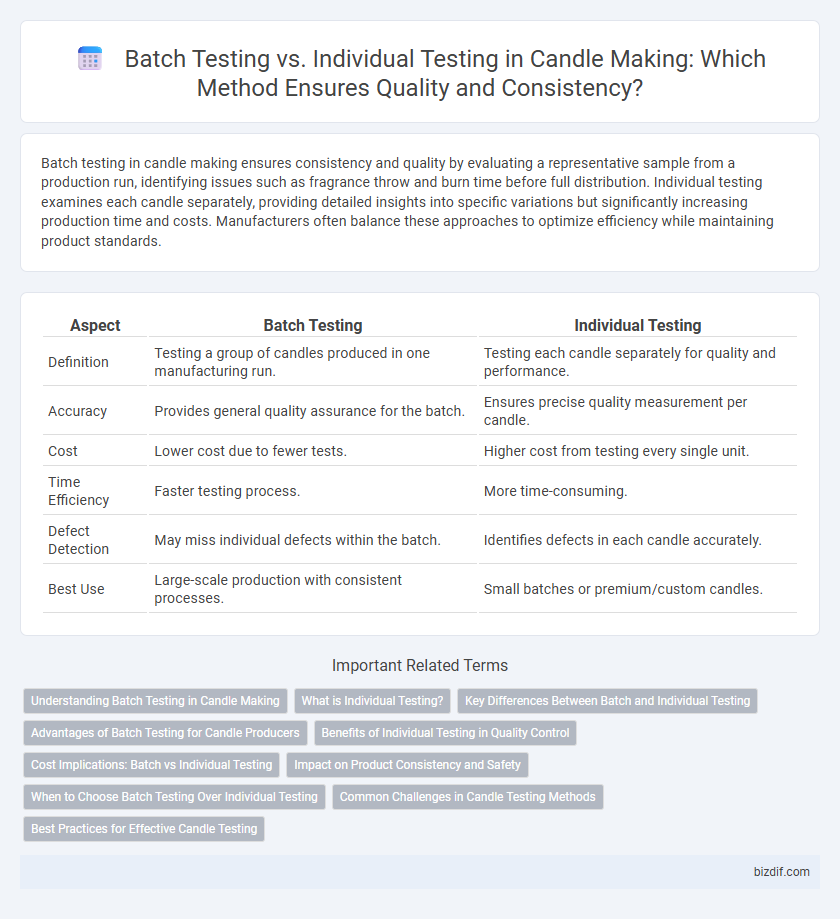

Batch testing in candle making ensures consistency and quality by evaluating a representative sample from a production run, identifying issues such as fragrance throw and burn time before full distribution. Individual testing examines each candle separately, providing detailed insights into specific variations but significantly increasing production time and costs. Manufacturers often balance these approaches to optimize efficiency while maintaining product standards.

Table of Comparison

| Aspect | Batch Testing | Individual Testing |

|---|---|---|

| Definition | Testing a group of candles produced in one manufacturing run. | Testing each candle separately for quality and performance. |

| Accuracy | Provides general quality assurance for the batch. | Ensures precise quality measurement per candle. |

| Cost | Lower cost due to fewer tests. | Higher cost from testing every single unit. |

| Time Efficiency | Faster testing process. | More time-consuming. |

| Defect Detection | May miss individual defects within the batch. | Identifies defects in each candle accurately. |

| Best Use | Large-scale production with consistent processes. | Small batches or premium/custom candles. |

Understanding Batch Testing in Candle Making

Batch testing in candle making involves evaluating a representative sample from a large production run to ensure consistency in scent, burn quality, and safety standards across all candles produced. This method identifies potential formulation or manufacturing issues before mass distribution, enhancing reliability and reducing waste. It is a cost-effective approach compared to individual testing, maintaining quality control while optimizing production efficiency.

What is Individual Testing?

Individual testing in candle making involves evaluating each candle separately to ensure quality and consistency in scent throw, burn time, and appearance. This process identifies defects or variations in every single candle, helping maintain high standards and customer satisfaction. Unlike batch testing, individual testing provides precise data for each product rather than aggregated results.

Key Differences Between Batch and Individual Testing

Batch testing in candle making involves evaluating a sample from an entire batch to ensure consistent fragrance throw, burn quality, and safety standards, while individual testing examines each candle separately for defects or variations. Batch testing enhances efficiency by identifying issues at a group level, whereas individual testing provides precise quality control for each product. Key differences lie in the scope, time investment, and level of detail, with batch testing suited for large-scale production and individual testing essential for high-end or small-batch candle makers.

Advantages of Batch Testing for Candle Producers

Batch testing in candle making allows producers to efficiently assess the consistency and quality of a whole production run, reducing time and costs associated with individual testing of each candle. This method ensures uniform scent throw, burn time, and safety standards across the batch, minimizing variability and improving customer satisfaction. By identifying defects or formulation issues early, batch testing streamlines quality control processes and increases production scalability for candle manufacturers.

Benefits of Individual Testing in Quality Control

Individual testing in candle making ensures precise quality control by evaluating each candle's burn time, scent throw, and wick performance, leading to consistent product reliability. This method identifies defects or inconsistencies in every single unit, preventing defective candles from reaching customers and enhancing overall satisfaction. Thorough individual testing reduces the risk of recalls and strengthens brand reputation through uncompromised quality standards.

Cost Implications: Batch vs Individual Testing

Batch testing in candle making significantly reduces costs by allowing multiple candles to be evaluated together, minimizing labor and material expenses per unit. Individual testing, while more precise, increases production costs due to the need for separate analysis of each candle, which consumes more time and resources. Manufacturers often favor batch testing to maintain budget efficiency without compromising essential quality control standards.

Impact on Product Consistency and Safety

Batch testing in candle making ensures uniformity in scent, burn time, and safety by evaluating a representative sample from each production batch, reducing variability and maintaining consistent quality standards. Individual testing, while more time-consuming, allows for precise identification of defects or variations in each candle, enhancing safety by catching anomalies that batch testing might miss. Implementing a balanced approach combining batch and individual testing optimizes product consistency and minimizes safety risks, crucial for consumer trust and regulatory compliance.

When to Choose Batch Testing Over Individual Testing

Batch testing is ideal when producing large quantities of candles with consistent formulas, as it ensures uniform quality and reduces testing time and costs. Choose batch testing when raw materials and processes remain unchanged across multiple units, allowing efficient detection of variations within the entire batch. Individual testing becomes unnecessary unless customization or small-scale production demands precise quality control for each candle.

Common Challenges in Candle Testing Methods

Batch testing in candle making often faces challenges such as inconsistent wax composition and temperature variations that affect scent throw and burn quality across the entire batch. Individual testing, while more precise, can be time-consuming and may not capture variability within the batch, leading to potential quality control gaps. Both methods struggle with accurately predicting long-term candle performance due to variables like wick behavior and fragrance oil stability during extended burns.

Best Practices for Effective Candle Testing

Batch testing in candle making ensures consistent fragrance throw and burn quality across multiple units, optimizing production efficiency and reducing defects. Individual testing, though time-consuming, provides detailed insights into each candle's performance, identifying anomalies in wick behavior or wax melt pool formation. Combining both methods balances scalability and precision, ensuring high-quality candles while minimizing waste and customer complaints.

Batch testing vs Individual testing Infographic

bizdif.com

bizdif.com