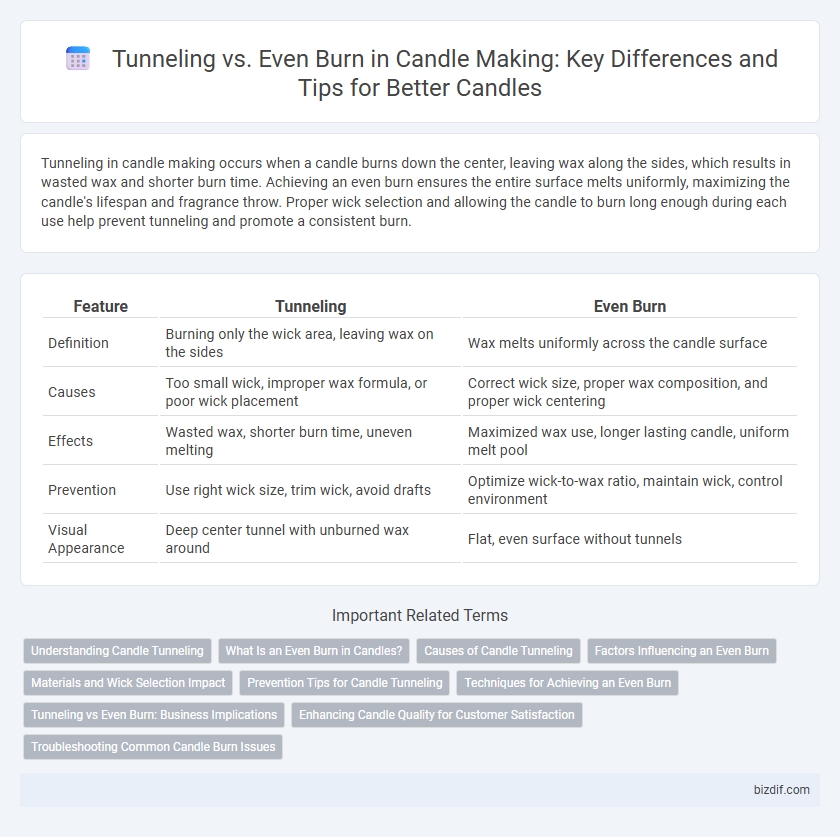

Tunneling in candle making occurs when a candle burns down the center, leaving wax along the sides, which results in wasted wax and shorter burn time. Achieving an even burn ensures the entire surface melts uniformly, maximizing the candle's lifespan and fragrance throw. Proper wick selection and allowing the candle to burn long enough during each use help prevent tunneling and promote a consistent burn.

Table of Comparison

| Feature | Tunneling | Even Burn |

|---|---|---|

| Definition | Burning only the wick area, leaving wax on the sides | Wax melts uniformly across the candle surface |

| Causes | Too small wick, improper wax formula, or poor wick placement | Correct wick size, proper wax composition, and proper wick centering |

| Effects | Wasted wax, shorter burn time, uneven melting | Maximized wax use, longer lasting candle, uniform melt pool |

| Prevention | Use right wick size, trim wick, avoid drafts | Optimize wick-to-wax ratio, maintain wick, control environment |

| Visual Appearance | Deep center tunnel with unburned wax around | Flat, even surface without tunnels |

Understanding Candle Tunneling

Candle tunneling occurs when a narrow channel forms down the center of the wax, causing uneven wax melting and reducing burn time. Understanding candle tunneling involves recognizing factors such as wick size, wax type, and burning duration that contribute to this issue. Optimizing wick placement and trimming ensures an even burn that maximizes candle longevity and fragrance release.

What Is an Even Burn in Candles?

An even burn in candles occurs when the wax melts uniformly across the entire surface, preventing tunneling and maximizing the candle's lifespan and fragrance release. Proper wick size and trimming are essential factors that promote an even burn by ensuring the flame remains steady and consumes the wax evenly. Achieving an even burn enhances safety, improves air quality, and delivers consistent illumination throughout the candle's use.

Causes of Candle Tunneling

Candle tunneling primarily occurs when the wick is too small for the candle's diameter, causing a narrow melt pool that fails to reach the edges. Using candles in drafty areas or cutting the wick too short also leads to uneven heat distribution, promoting tunneling. Poor wax formulation or additives that increase the melting point may prevent the wax from fully liquefying, intensifying the tunneling effect.

Factors Influencing an Even Burn

Factors influencing an even burn in candle making include wick size, wax type, and candle diameter. Using a wick that matches the candle's diameter ensures the flame heats the wax evenly, preventing tunneling where wax burns down the center while solid wax remains on the sides. Proper temperature during pouring and allowing the candle to cure also contribute to a uniform melt pool and consistent burn.

Materials and Wick Selection Impact

Tunneling in candle making often results from improper wick selection or incompatible wax materials, causing the flame to burn unevenly and deepening the center of the candle. Choosing the right wick size and type, matched to the wax blend--such as cotton or wood wicks for soy or paraffin wax--ensures a consistent heat distribution that promotes an even burn. Materials with additives or a high fragrance load can also influence wick performance, making precise wick selection critical to prevent tunneling and achieve a uniform melting pool.

Prevention Tips for Candle Tunneling

Preventing candle tunneling starts with trimming the wick to 1/4 inch before each burn to ensure an even flame and optimal wax melt pool. Allow the candle to burn long enough for the wax to melt across the entire surface during the first use, preventing uneven wax levels. Avoid burning candles in drafty areas, as fluctuations in airflow can cause the flame to create tunnels instead of a consistent, even burn.

Techniques for Achieving an Even Burn

Achieving an even burn in candle making requires specific techniques such as selecting the correct wick size tailored to the candle's diameter and wax type, ensuring consistent temperature control during the pouring process, and allowing proper curing time for the wax to solidify uniformly. Proper wick centering prevents tunneling, where the wax burns down the middle, leaving unmelted wax around the edges. Monitoring and adjusting these factors results in a smooth, efficient burn that maximizes candle longevity and fragrance throw.

Tunneling vs Even Burn: Business Implications

Tunneling in candle making leads to wasted wax and reduced burn time, negatively impacting customer satisfaction and increasing return rates. Even burn enhances product quality, ensuring optimal use of wax, which boosts brand reputation and customer loyalty. Businesses prioritizing even burn achieve better cost efficiency and higher profit margins due to consistent, high-performing candles.

Enhancing Candle Quality for Customer Satisfaction

Tunneling in candles causes uneven wax melting, reducing burn time and overall candle quality, which can disappoint customers. An even burn ensures the entire candle surface melts uniformly, maximizing scent throw and enhancing visual appeal. Optimizing wax formulation and wick size is essential to prevent tunneling and deliver a premium candle experience that boosts customer satisfaction.

Troubleshooting Common Candle Burn Issues

Tunneling occurs when a candle burns down the center, leaving excess wax on the sides, often caused by improper wick size or drafty conditions. An even burn requires a correctly sized wick and a stable environment to ensure the flame melts the wax uniformly across the surface. Troubleshooting common candle burn issues involves adjusting wick height, avoiding drafts, and ensuring the candle is burned long enough for the entire surface to melt evenly on the first use.

Tunneling vs Even burn Infographic

bizdif.com

bizdif.com