Hand-poured candles offer unique craftsmanship and attention to detail, resulting in distinct textures and personalized scents. Machine-made candles provide consistent quality and uniformity, ideal for mass production with precise safety standards. Choosing between the two depends on the desired balance between artisanal charm and efficient manufacturing.

Table of Comparison

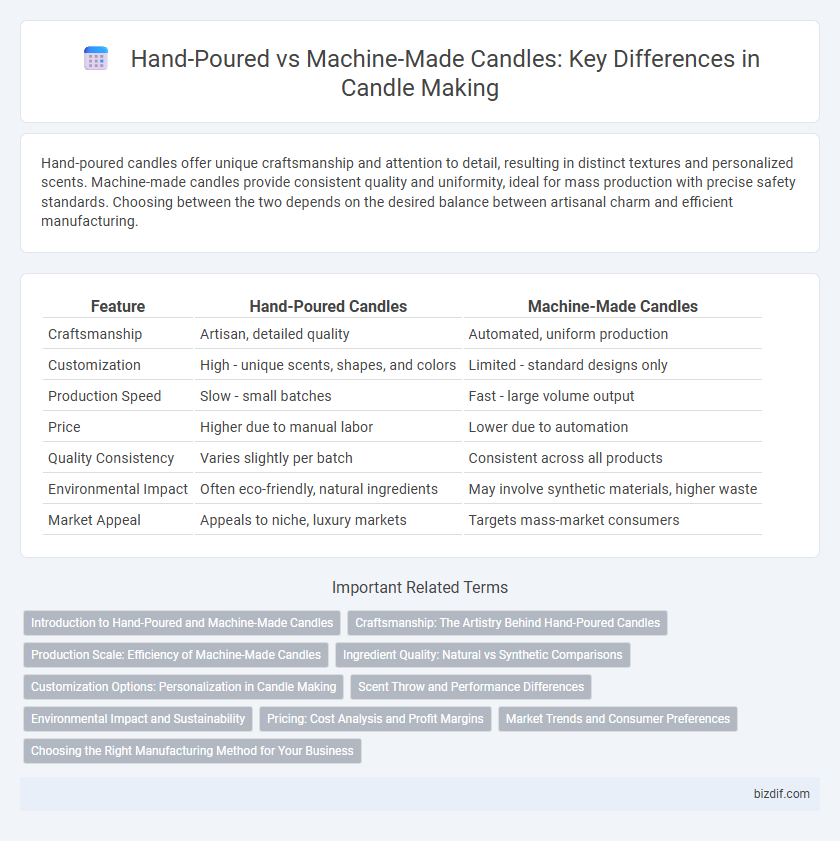

| Feature | Hand-Poured Candles | Machine-Made Candles |

|---|---|---|

| Craftsmanship | Artisan, detailed quality | Automated, uniform production |

| Customization | High - unique scents, shapes, and colors | Limited - standard designs only |

| Production Speed | Slow - small batches | Fast - large volume output |

| Price | Higher due to manual labor | Lower due to automation |

| Quality Consistency | Varies slightly per batch | Consistent across all products |

| Environmental Impact | Often eco-friendly, natural ingredients | May involve synthetic materials, higher waste |

| Market Appeal | Appeals to niche, luxury markets | Targets mass-market consumers |

Introduction to Hand-Poured and Machine-Made Candles

Hand-poured candles are crafted individually, allowing for careful attention to detail and the use of high-quality ingredients such as natural soy or beeswax. Machine-made candles, produced in large quantities through automated processes, offer consistent shapes and sizes but may contain synthetic additives. The choice between hand-poured and machine-made candles impacts factors like fragrance strength, burn time, and environmental footprint.

Craftsmanship: The Artistry Behind Hand-Poured Candles

Hand-poured candles exemplify superior craftsmanship, with artisans meticulously controlling the wax temperature, pouring speed, and scent infusion to create unique, high-quality products. This manual process allows for intricate design elements and personalized fragrance blends that machine-made candles often lack. The artistry behind hand-poured candles results in a more refined finish, enhanced fragrance retention, and a distinctive aesthetic appeal valued by connoisseurs and collectors.

Production Scale: Efficiency of Machine-Made Candles

Machine-made candles offer significantly higher production efficiency, enabling manufacturers to produce thousands of units daily compared to the limited output of hand-poured candles. Automated processes ensure consistent quality and speed, reducing labor costs and time per candle. This scalability makes machine-made candles ideal for mass-market retail and large-scale distribution channels.

Ingredient Quality: Natural vs Synthetic Comparisons

Hand-poured candles typically use higher-quality natural ingredients like beeswax, soy wax, and essential oils, ensuring a cleaner burn and eco-friendly composition. Machine-made candles often rely on synthetic waxes and fragrance oils, which can emit stronger artificial scents and potential toxins. Selecting natural ingredients in hand-poured candles enhances overall safety, scent authenticity, and environmental sustainability.

Customization Options: Personalization in Candle Making

Hand-poured candles offer extensive customization options, allowing artisans to tailor scents, colors, and shapes precisely to customer preferences. Machine-made candles prioritize uniformity and mass production, limiting personalized features and unique designs. Customization in hand-poured candle making enhances the customer experience by providing bespoke, artisanal products that reflect individual style and ambiance.

Scent Throw and Performance Differences

Hand-poured candles typically offer a stronger scent throw due to the careful layering of fragrance oils and slower cooling process, which enhances scent diffusion. Machine-made candles, while produced faster and more uniformly, often have a less intense aroma because of the rapid manufacturing timeline and consistent wax density. Performance-wise, hand-poured candles usually burn more evenly and slowly, providing a longer-lasting fragrance experience compared to the sometimes uneven burn and quicker melting of machine-made candles.

Environmental Impact and Sustainability

Hand-poured candles typically have a lower environmental impact due to smaller production scales and reduced energy consumption compared to machine-made candles, which often require large factories and significant power use. Sustainable materials, such as soy wax or beeswax, are more commonly used in artisanal hand-poured candles, minimizing reliance on petroleum-based paraffin wax prevalent in mass production. Choosing hand-poured candles supports eco-friendly practices by promoting biodegradable packaging and reducing industrial waste.

Pricing: Cost Analysis and Profit Margins

Hand-poured candles typically have higher production costs due to labor-intensive processes and smaller batch sizes, resulting in higher retail prices but potentially larger profit margins per unit. Machine-made candles benefit from economies of scale, lowering production costs and enabling competitive pricing but often yielding slimmer profit margins. Pricing strategies must balance material expenses, labor investment, and market positioning to maximize profitability in hand-poured versus machine-made candle segments.

Market Trends and Consumer Preferences

Hand-poured candles dominate niche markets due to their artisanal appeal and customization options, attracting consumers seeking unique, high-quality scents and eco-friendly ingredients. Machine-made candles, favored for mass production, offer consistency and affordability, appealing to price-sensitive buyers and large retailers. Market trends indicate a growing consumer shift towards handcrafted candles driven by sustainability and personalization, influencing brand strategies and product development.

Choosing the Right Manufacturing Method for Your Business

Hand-poured candles offer artisanal quality and customization, appealing to customers seeking unique, small-batch products with intricate scent blends and eco-friendly ingredients. Machine-made candles provide scalability, consistent output, and lower labor costs, making them ideal for businesses targeting mass production and broader market distribution. Evaluating your brand's target audience, production volume, and budget constraints is crucial when choosing between hand-poured craftsmanship and automated manufacturing processes.

Hand-poured candles vs Machine-made candles Infographic

bizdif.com

bizdif.com