Hand pouring in candle making allows for precise control over wax temperature and fragrance distribution, resulting in a customized and artisanal finish. Machine pouring offers consistent volume and speed, ideal for large-scale production with uniform quality. Choosing between hand and machine pouring depends on balancing craftsmanship with efficiency in candle manufacturing.

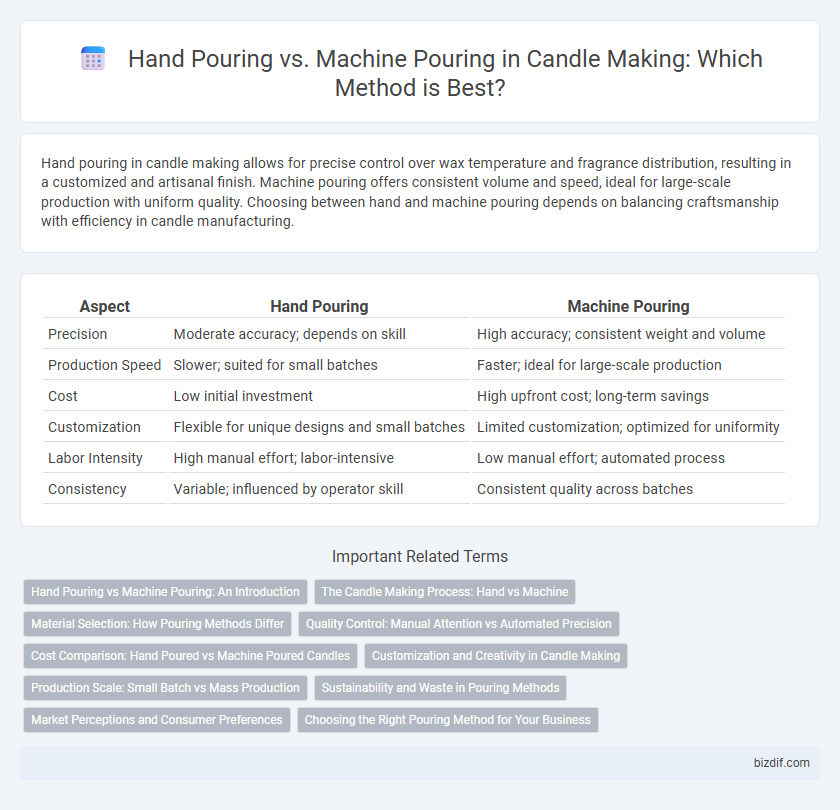

Table of Comparison

| Aspect | Hand Pouring | Machine Pouring |

|---|---|---|

| Precision | Moderate accuracy; depends on skill | High accuracy; consistent weight and volume |

| Production Speed | Slower; suited for small batches | Faster; ideal for large-scale production |

| Cost | Low initial investment | High upfront cost; long-term savings |

| Customization | Flexible for unique designs and small batches | Limited customization; optimized for uniformity |

| Labor Intensity | High manual effort; labor-intensive | Low manual effort; automated process |

| Consistency | Variable; influenced by operator skill | Consistent quality across batches |

Hand Pouring vs Machine Pouring: An Introduction

Hand pouring in candle making allows for greater control over wax temperature and fragrance distribution, resulting in a more artisanal, customized product. Machine pouring offers higher production speed and consistency, ideal for large-scale manufacturing with uniform quality. Choosing between hand and machine pouring depends on the desired balance between craftsmanship and efficiency in candle production.

The Candle Making Process: Hand vs Machine

Hand pouring in the candle making process offers artisans greater control over wax temperature and fragrance dispersion, resulting in customized, high-quality candles with unique aesthetic features. Machine pouring ensures consistent volume and uniformity, enhancing production speed and scalability for large batches while maintaining precise temperature regulation. Each method impacts the candle's texture, burn quality, and scent throw, making choice dependent on production goals and desired product characteristics.

Material Selection: How Pouring Methods Differ

Hand pouring in candle making allows for precise control over the temperature and flow rate, which is crucial when working with delicate wax blends like soy or beeswax to maintain their natural properties. Machine pouring, commonly used in mass production, can handle a wider range of materials but often requires waxes that solidify uniformly, such as paraffin, to ensure consistent mold filling and solidification. Material selection directly impacts the choice between hand and machine pouring, as the method determines the wax's thermal stability, fragrance retention, and appearance in the final candle product.

Quality Control: Manual Attention vs Automated Precision

Hand pouring in candle making allows for meticulous quality control through manual attention, enabling artisans to adjust wax temperature and fragrance levels in real-time to ensure optimal scent throw and burn consistency. Machine pouring offers automated precision with consistent fill volumes and reduced human error, resulting in uniform candles that meet strict production standards. Balancing these methods often depends on the scale of production and the desired level of customization in candle quality.

Cost Comparison: Hand Poured vs Machine Poured Candles

Hand poured candles typically involve higher labor costs due to the meticulous process and time-intensive craftsmanship, making them more expensive per unit. In contrast, machine poured candles benefit from automation, reducing labor expenses and allowing for larger batch production, which lowers the overall manufacturing cost. However, hand poured candles often offer superior quality and customization options that justify the premium price for many consumers.

Customization and Creativity in Candle Making

Hand pouring in candle making allows artisans to customize each batch with unique scents, colors, and designs, fostering greater creativity and personalized products. Machine pouring standardizes the process, enhancing efficiency and consistency but limiting the scope for individual artistic expression. Small-batch, hand-poured candles often appeal to niche markets seeking bespoke and artisanal qualities.

Production Scale: Small Batch vs Mass Production

Hand pouring offers precision and control ideal for small batch candle making, ensuring unique, artisanal quality with each piece. Machine pouring enables high-volume, consistent production suited for mass production, increasing efficiency and reducing labor costs. Choosing between these methods depends on the desired production scale, quality standards, and customization needs.

Sustainability and Waste in Pouring Methods

Hand pouring in candle making typically generates less waste due to precise control over wax usage, promoting sustainability by minimizing excess material. Machine pouring offers higher efficiency but may result in increased wax spillage and leftover batches, impacting waste management negatively. Choosing hand pouring supports eco-friendly practices through reduced resource consumption and lower environmental footprint.

Market Perceptions and Consumer Preferences

Hand pouring in candle making is often perceived as artisanal and authentic, attracting consumers who value craftsmanship and uniqueness. Machine pouring offers consistency and scalability, appealing to mass-market buyers seeking uniform quality and faster production. Market preferences tend to favor hand-poured candles in premium segments, while machine-poured options dominate commercial and gift markets due to affordability and availability.

Choosing the Right Pouring Method for Your Business

Hand pouring offers precise control over wax temperature and fragrance distribution, making it ideal for small batches or artisan candles where quality and customization are paramount. Machine pouring increases production speed and consistency, best suited for large-scale operations requiring uniformity and efficiency. Selecting the right pouring method depends on your business's scale, product range, and quality standards to balance craftsmanship with productivity.

Hand pouring vs Machine pouring Infographic

bizdif.com

bizdif.com