Hand-poured candles offer unique craftsmanship and personalized scents that machine-made candles often lack, providing a distinct, artisanal touch. Machine-made candles are produced quickly and consistently, ensuring uniformity in size, shape, and fragrance strength across large batches. Choosing hand-poured candles supports small businesses and allows for custom blends, while machine-made options cater to affordability and mass availability.

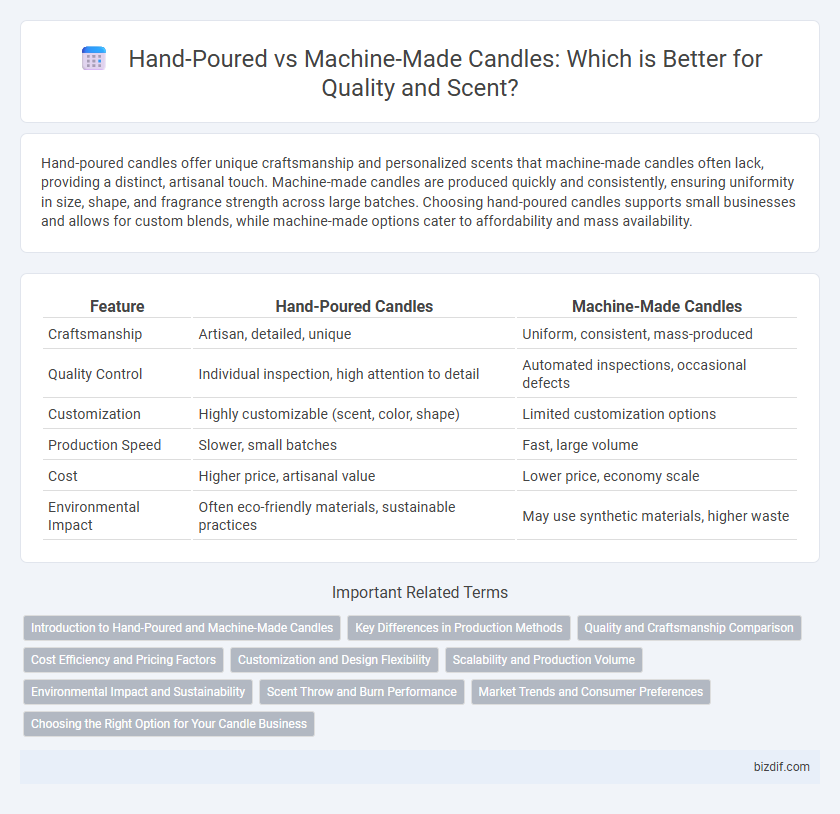

Table of Comparison

| Feature | Hand-Poured Candles | Machine-Made Candles |

|---|---|---|

| Craftsmanship | Artisan, detailed, unique | Uniform, consistent, mass-produced |

| Quality Control | Individual inspection, high attention to detail | Automated inspections, occasional defects |

| Customization | Highly customizable (scent, color, shape) | Limited customization options |

| Production Speed | Slower, small batches | Fast, large volume |

| Cost | Higher price, artisanal value | Lower price, economy scale |

| Environmental Impact | Often eco-friendly materials, sustainable practices | May use synthetic materials, higher waste |

Introduction to Hand-Poured and Machine-Made Candles

Hand-poured candles are crafted by artisans who carefully pour melted wax into molds, allowing for precise control over ingredients and designs that produce unique, high-quality products. Machine-made candles are produced using automated processes that enable mass production with consistent shapes and sizes, reducing costs and increasing availability. Understanding the differences in manufacturing techniques helps consumers choose between customizable hand-poured candles and efficient, standardized machine-made options.

Key Differences in Production Methods

Hand-poured candles are crafted by manually pouring melted wax into molds, allowing precise control over temperature and fragrance infusion, resulting in unique variations and artisanal quality. Machine-made candles are produced using automated systems that ensure uniformity, speed, and large-scale output, with consistent dimensions and appearance. The key differences lie in the level of craftsmanship, production speed, and customization capabilities between hand-poured and machine-made candle manufacturing.

Quality and Craftsmanship Comparison

Hand-poured candles exhibit superior craftsmanship through artisanal techniques that ensure precise wax blending, personalized scent infusion, and meticulous curing processes, resulting in a unique, high-quality product. Machine-made candles offer uniformity and mass production efficiency but often lack the detailed attention to texture, scent layering, and aesthetic nuances found in hand-poured varieties. The artisanal approach elevates fragrance throw and burn consistency, making hand-poured candles favored for premium and bespoke candle collections.

Cost Efficiency and Pricing Factors

Hand-poured candles often incur higher production costs due to labor-intensive processes and slower output rates, resulting in premium pricing. Machine-made candles benefit from automation, significantly reducing manufacturing expenses and allowing for lower retail prices. Pricing factors also include material quality, customization options, and batch size, with machine-made candles favoring mass production economies of scale.

Customization and Design Flexibility

Hand-poured candles offer unparalleled customization and design flexibility, allowing artisans to experiment with unique scents, colors, and shapes tailored to specific preferences. Machine-made candles, while efficient for mass production, typically follow standardized designs that limit personalization options. This distinction makes hand-poured candles ideal for bespoke creations and artistic expression in candle making.

Scalability and Production Volume

Hand-poured candles emphasize artisanal quality but face limitations in scalability and production volume due to time-intensive processes. Machine-made candles enable mass production with consistent output, significantly increasing scalability and meeting high market demand efficiently. Automation reduces labor costs and accelerates production cycles, making machine manufacturing ideal for large-scale candle businesses.

Environmental Impact and Sustainability

Hand-poured candles typically have a lower environmental impact due to smaller batch sizes, reduced energy consumption, and the use of natural, biodegradable ingredients like soy or beeswax. Machine-made candles often involve mass production processes that consume more energy and rely on synthetic materials, which can contribute to higher carbon footprints and increased waste. Choosing hand-poured candles supports sustainable practices by minimizing resource usage and encouraging eco-friendly sourcing.

Scent Throw and Burn Performance

Hand-poured candles often exhibit superior scent throw and more consistent burn performance due to the meticulous control over wax temperature and fragrance distribution. Machine-made candles may have less intense fragrance diffusion and uneven burning as industrial processes prioritize speed over precision. Research shows that artisan hand-poured candles maintain fragrance integrity longer and provide a cleaner, slower burn compared to mass-produced alternatives.

Market Trends and Consumer Preferences

Hand-poured candles dominate niche markets due to their artisanal quality and customizable features, appealing to consumers seeking unique, high-quality products. Machine-made candles capture mass markets by offering consistent quality and lower prices, driving widespread adoption in retail chains. Current market trends indicate a growing consumer preference for hand-poured candles in boutique and luxury segments, reflecting increased demand for craftsmanship and personalization.

Choosing the Right Option for Your Candle Business

Hand-poured candles offer unique craftsmanship and customization that appeals to niche markets seeking artisanal quality. Machine-made candles provide higher production speed and consistency, ideal for scaling businesses targeting mass-market distribution. Evaluating factors like target audience, production volume, and budget helps determine the best manufacturing method for your candle business.

Hand-poured vs Machine-made Infographic

bizdif.com

bizdif.com