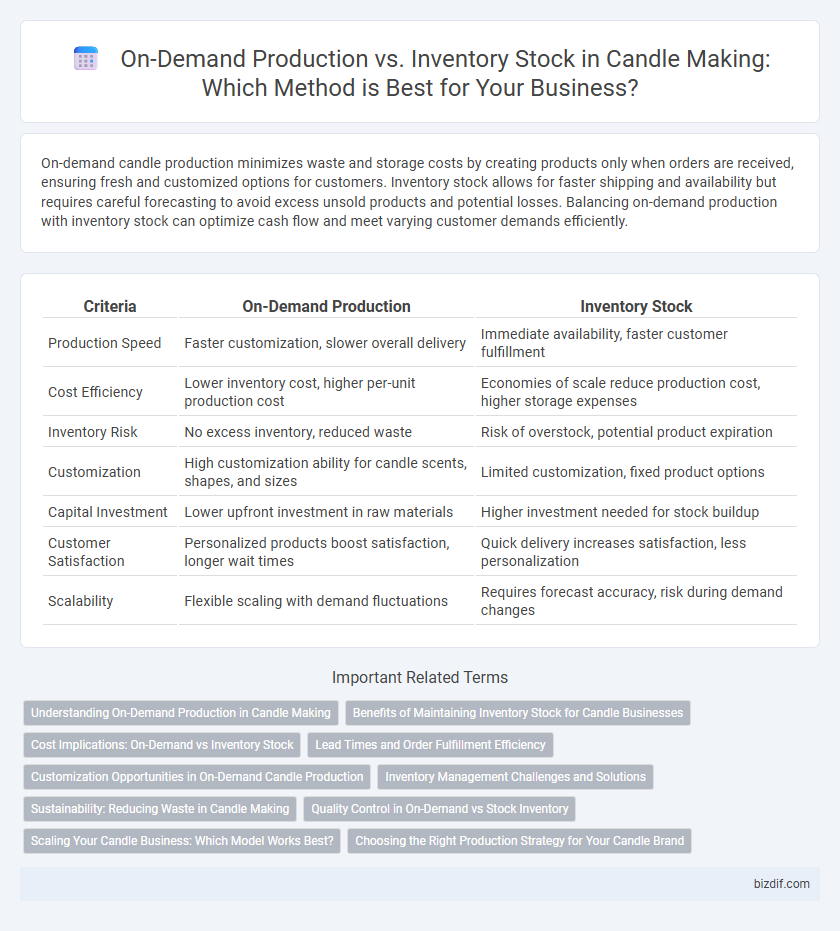

On-demand candle production minimizes waste and storage costs by creating products only when orders are received, ensuring fresh and customized options for customers. Inventory stock allows for faster shipping and availability but requires careful forecasting to avoid excess unsold products and potential losses. Balancing on-demand production with inventory stock can optimize cash flow and meet varying customer demands efficiently.

Table of Comparison

| Criteria | On-Demand Production | Inventory Stock |

|---|---|---|

| Production Speed | Faster customization, slower overall delivery | Immediate availability, faster customer fulfillment |

| Cost Efficiency | Lower inventory cost, higher per-unit production cost | Economies of scale reduce production cost, higher storage expenses |

| Inventory Risk | No excess inventory, reduced waste | Risk of overstock, potential product expiration |

| Customization | High customization ability for candle scents, shapes, and sizes | Limited customization, fixed product options |

| Capital Investment | Lower upfront investment in raw materials | Higher investment needed for stock buildup |

| Customer Satisfaction | Personalized products boost satisfaction, longer wait times | Quick delivery increases satisfaction, less personalization |

| Scalability | Flexible scaling with demand fluctuations | Requires forecast accuracy, risk during demand changes |

Understanding On-Demand Production in Candle Making

On-demand production in candle making involves creating candles only when orders are received, minimizing waste and storage costs while enabling customization. This method enhances cash flow by reducing inventory holding and allows producers to adapt quickly to changing customer preferences or seasonal trends. Implementing on-demand production requires efficient supply chain management and flexible manufacturing processes to meet delivery deadlines without compromising quality.

Benefits of Maintaining Inventory Stock for Candle Businesses

Maintaining inventory stock in candle making ensures faster order fulfillment, enhancing customer satisfaction and repeat business. It reduces the risk of production delays during peak seasons or unexpected demand spikes by having ready-to-ship products. Inventory stock also allows businesses to benefit from bulk purchasing of raw materials, lowering production costs and increasing profit margins.

Cost Implications: On-Demand vs Inventory Stock

On-demand candle production minimizes upfront inventory costs by producing only what is needed, reducing storage expenses and waste from unsold stock. Inventory stock requires significant capital investment in raw materials and finished candles, increasing holding costs and the risk of product obsolescence or damage. Balancing on-demand and inventory strategies optimizes cash flow and cost efficiency in candle manufacturing operations.

Lead Times and Order Fulfillment Efficiency

On-demand production in candle making significantly reduces lead times by manufacturing products only after receiving orders, ensuring fresh stock and minimizing storage costs. Inventory stock allows for faster order fulfillment since products are pre-made and readily available, but it can result in higher holding expenses and risk of excess inventory. Balancing on-demand production and inventory stock optimizes efficiency by aligning manufacturing schedules with fluctuating customer demand and peak order volumes.

Customization Opportunities in On-Demand Candle Production

On-demand candle production enables extensive customization opportunities by allowing makers to tailor scents, colors, and shapes according to individual customer preferences without the constraints of pre-made inventory stock. This flexibility reduces waste and storage costs while meeting unique market demands more effectively. Custom scents and personalized designs can be created quickly, enhancing customer satisfaction and fostering brand loyalty in a competitive candle making industry.

Inventory Management Challenges and Solutions

Inventory stock in candle making often leads to challenges such as overstocking, product obsolescence, and increased storage costs due to fluctuations in demand and seasonal trends. Implementing real-time inventory tracking systems and demand forecasting software can optimize stock levels, reduce waste, and enhance cash flow management. Lean inventory practices and just-in-time replenishment further minimize holding costs while ensuring the availability of raw materials and finished products.

Sustainability: Reducing Waste in Candle Making

On-demand candle production significantly reduces waste by minimizing overstock and unsold inventory, aligning with sustainable manufacturing principles. Inventory stock often leads to excess candles that may expire or degrade, increasing material waste and environmental impact. Implementing on-demand systems optimizes resource use, lowers emissions from storage and transportation, and supports eco-friendly practices in candle making.

Quality Control in On-Demand vs Stock Inventory

On-demand production in candle making allows for stringent quality control by minimizing storage time and reducing the risk of product degradation, ensuring each candle meets freshness and consistency standards. In contrast, inventory stock often faces challenges such as wax discoloration, scent fading, and wick deformation due to prolonged storage, which can compromise the final product's quality. Implementing on-demand manufacturing enhances customer satisfaction by delivering candles with optimal scent throw, burn time, and aesthetic appeal.

Scaling Your Candle Business: Which Model Works Best?

On-demand production minimizes upfront inventory costs and reduces waste, making it ideal for scaling a candle business with diverse, customizable products. Inventory stock allows faster order fulfillment and bulk purchasing discounts, supporting high-volume sales and consistent demand. Choosing the right model depends on balancing cash flow flexibility with customer expectations for delivery speed and product variety.

Choosing the Right Production Strategy for Your Candle Brand

On-demand production minimizes waste and allows for customization, ideal for small-scale or artisanal candle brands seeking flexibility. Inventory stock supports faster order fulfillment and consistency, benefiting larger brands with steady demand and established product lines. Evaluating order volume, cash flow, and market trends helps candle makers choose the best strategy for balancing efficiency and customer satisfaction.

On-demand production vs Inventory stock Infographic

bizdif.com

bizdif.com