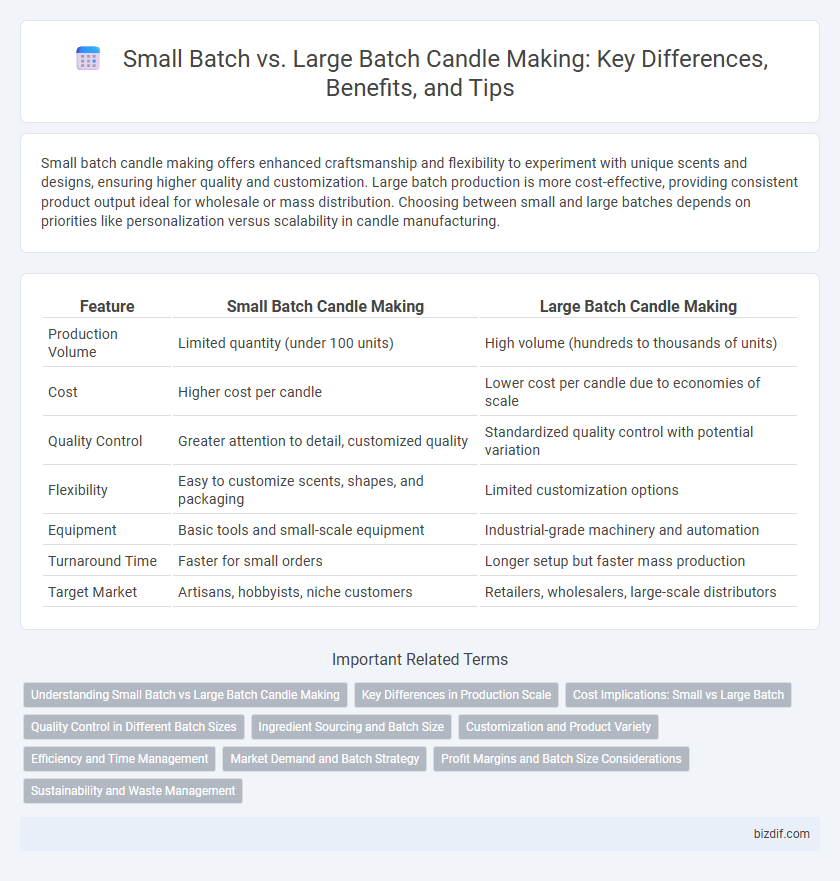

Small batch candle making offers enhanced craftsmanship and flexibility to experiment with unique scents and designs, ensuring higher quality and customization. Large batch production is more cost-effective, providing consistent product output ideal for wholesale or mass distribution. Choosing between small and large batches depends on priorities like personalization versus scalability in candle manufacturing.

Table of Comparison

| Feature | Small Batch Candle Making | Large Batch Candle Making |

|---|---|---|

| Production Volume | Limited quantity (under 100 units) | High volume (hundreds to thousands of units) |

| Cost | Higher cost per candle | Lower cost per candle due to economies of scale |

| Quality Control | Greater attention to detail, customized quality | Standardized quality control with potential variation |

| Flexibility | Easy to customize scents, shapes, and packaging | Limited customization options |

| Equipment | Basic tools and small-scale equipment | Industrial-grade machinery and automation |

| Turnaround Time | Faster for small orders | Longer setup but faster mass production |

| Target Market | Artisans, hobbyists, niche customers | Retailers, wholesalers, large-scale distributors |

Understanding Small Batch vs Large Batch Candle Making

Small batch candle making involves producing limited quantities, allowing for greater control over quality, customization, and experimentation with unique scents and designs. Large batch candle making emphasizes efficiency and cost-effectiveness by creating significant volumes, often standardizing ingredients and processes to ensure consistency. Understanding the differences helps artisans balance creativity with scalability to meet market demands effectively.

Key Differences in Production Scale

Small batch candle making involves producing limited quantities, emphasizing craftsmanship, customization, and quality control, suitable for artisanal and niche markets. Large batch production focuses on mass manufacturing, utilizing automated processes to achieve higher volume, consistency, and cost efficiency for mainstream distribution. The key differences lie in scale, production speed, resource allocation, and flexibility in design variations.

Cost Implications: Small vs Large Batch

Producing candles in small batches often results in higher costs per unit due to inefficient use of materials and equipment, along with increased labor expenses. Large batch production benefits from economies of scale, reducing raw material costs and increasing overall manufacturing efficiency. However, small batches offer flexibility for customization and testing new scents without significant upfront investment.

Quality Control in Different Batch Sizes

Small batch candle making allows for meticulous quality control, ensuring consistent scent throw, wax texture, and wick placement with each candle produced. Large batch production increases efficiency and output but poses challenges in maintaining uniformity, often requiring automated monitoring systems and rigorous sampling protocols. The difference in batch size directly influences the ability to detect imperfections early and adjust formulations for optimal candle performance.

Ingredient Sourcing and Batch Size

Small batch candle making allows for precise control over ingredient sourcing, often enabling the use of higher-quality, artisanal waxes and fragrances sourced in limited quantities. Large batch production requires bulk purchasing, which can reduce costs but may limit access to rare or premium materials due to volume constraints. Batch size directly influences ingredient freshness and customization potential, with smaller batches supporting more experimental and niche fragrance blends.

Customization and Product Variety

Small batch candle making allows for greater customization, enabling artisans to experiment with diverse scents, colors, and shapes tailored to niche markets. Large batch production emphasizes consistency and scale, often limiting product variety due to standardized processes. Customization thrives in small batches, while large batches maximize efficiency and meet high-volume demand.

Efficiency and Time Management

Small batch candle making allows for greater control over quality and customization but can be less efficient due to frequent setup and cleanup times. Large batch production maximizes time management by reducing repetition of preparation steps and increasing output per session. Balancing batch size is crucial to optimize workflow, minimize waste, and meet production deadlines effectively.

Market Demand and Batch Strategy

Small batch candle making caters to niche markets and allows for customization, aligning well with fluctuating or specialized market demand. Large batch production suits high-demand, consistent markets by maximizing efficiency and reducing per-unit costs. Choosing the right batch strategy depends on balancing market demand forecasts with production scalability and inventory management goals.

Profit Margins and Batch Size Considerations

Small batch candle making allows for higher profit margins per unit due to premium pricing and reduced waste, though it requires more labor-intensive processes and time investment. Large batch production benefits from economies of scale, lowering the cost per candle but often resulting in thinner profit margins and higher upfront material costs. Choosing between small and large batch sizes depends on balancing operational capacity, target market demand, and desired profit margin optimization.

Sustainability and Waste Management

Small batch candle making minimizes waste by using precise material quantities, reducing excess and unsold inventory, which supports sustainable production practices. Large batch production often leads to overproduction and increased packaging waste, posing challenges for efficient resource management. Prioritizing small batch processes enhances eco-friendly operations by enabling better control over raw material usage and waste disposal.

Small batch vs Large batch Infographic

bizdif.com

bizdif.com