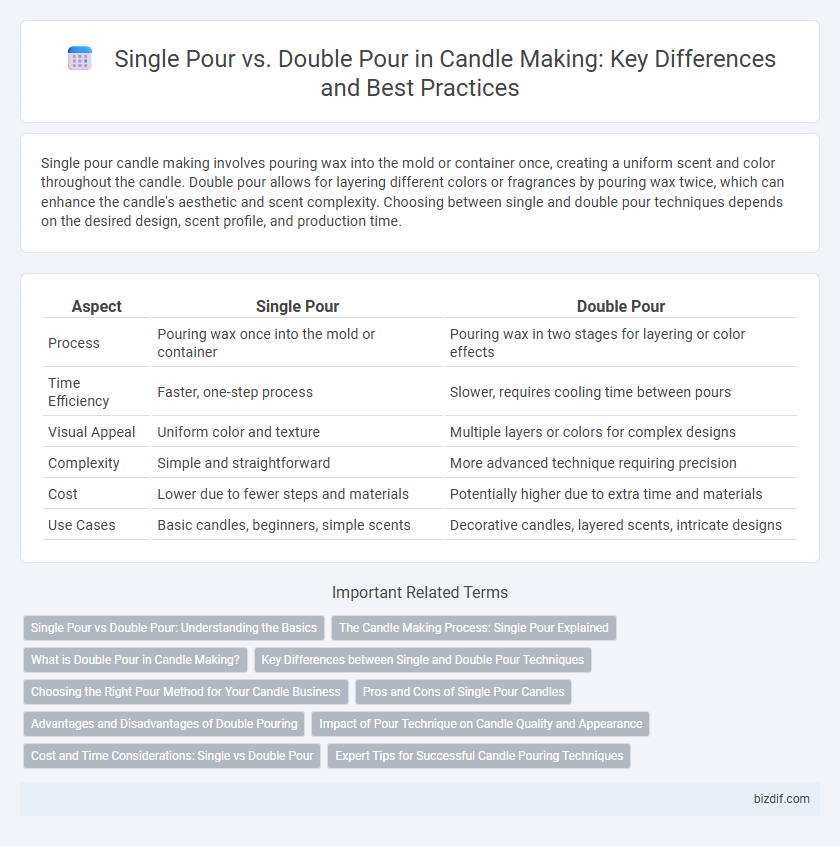

Single pour candle making involves pouring wax into the mold or container once, creating a uniform scent and color throughout the candle. Double pour allows for layering different colors or fragrances by pouring wax twice, which can enhance the candle's aesthetic and scent complexity. Choosing between single and double pour techniques depends on the desired design, scent profile, and production time.

Table of Comparison

| Aspect | Single Pour | Double Pour |

|---|---|---|

| Process | Pouring wax once into the mold or container | Pouring wax in two stages for layering or color effects |

| Time Efficiency | Faster, one-step process | Slower, requires cooling time between pours |

| Visual Appeal | Uniform color and texture | Multiple layers or colors for complex designs |

| Complexity | Simple and straightforward | More advanced technique requiring precision |

| Cost | Lower due to fewer steps and materials | Potentially higher due to extra time and materials |

| Use Cases | Basic candles, beginners, simple scents | Decorative candles, layered scents, intricate designs |

Single Pour vs Double Pour: Understanding the Basics

Single pour candles involve pouring the entire wax mixture into the mold at once, resulting in a uniform texture and quicker production time. Double pour candles require two separate pours, allowing for better control over scent layering and reducing air bubbles or imperfections. Understanding these basic differences helps candle makers choose the optimal technique for desired aesthetics and fragrance release.

The Candle Making Process: Single Pour Explained

Single pour candle making involves pouring melted wax into the mold or container once, allowing it to cool and solidify in a consistent layer. This method streamlines production and reduces cooling time, making it ideal for simple designs and uniform candles. The single pour process helps minimize air bubbles and ensures a smooth, even surface for a clean, professional finish.

What is Double Pour in Candle Making?

Double pour in candle making refers to the technique where wax is poured into the mold or container in two separate stages, allowing the first layer to partially solidify before adding the second. This method enhances the candle's structural integrity and reduces imperfections such as sinkholes or uneven surfaces. Double pouring is commonly used for layered or multi-scented candles to achieve distinct color separation and fragrance blending.

Key Differences between Single and Double Pour Techniques

Single pour candle making involves pouring melted wax into a mold or container in one continuous process, which creates a uniform finish and is ideal for simpler designs and faster production. Double pour technique requires two separate wax pours, often with a cooling period between, allowing for layered colors, intricate designs, and improved structural integrity. Key differences include the complexity of appearance, time investment, and the ability to incorporate multiple wax types or scents.

Choosing the Right Pour Method for Your Candle Business

Selecting the ideal pour method directly impacts candle quality and production efficiency, with single pour offering faster creation and consistent texture, while double pour ensures enhanced scent layering and structural integrity. For businesses prioritizing speed and cost-effectiveness, single pour suits mass production, whereas double pour caters to premium, multi-layered candle lines. Understanding your target market and product goals helps optimize ingredient use, curing times, and scent diffusion for competitive candle offerings.

Pros and Cons of Single Pour Candles

Single pour candles offer a smooth, consistent surface and faster production time, making them ideal for small batches and beginners in candle making. They can sometimes result in uneven scent distribution compared to double pour methods, which may affect the candle's fragrance throw. Single pour candles also tend to have less durability in layered designs, limiting creative options but enhancing efficiency in simple candle styles.

Advantages and Disadvantages of Double Pouring

Double pouring in candle making offers better color layering and enhanced scent distribution, resulting in visually appealing candles with richer fragrance profiles. However, this method requires more time and precision to avoid uneven surfaces or color bleeding between layers. While double pouring can improve aesthetic and olfactory qualities, it demands careful temperature control and increased labor compared to single pour techniques.

Impact of Pour Technique on Candle Quality and Appearance

Single pour techniques in candle making create a uniform wax surface with fewer imperfections, resulting in a smoother, consistent appearance and improved structural integrity. Double pour methods allow for layering effects and enhanced scent throw by controlling fragrance oil distribution, but may introduce visible lines and variability in texture. The choice between single and double pour impacts not only the aesthetic appeal but also burn quality, with double pours offering customization at the expense of potential visual inconsistencies.

Cost and Time Considerations: Single vs Double Pour

Single pour candle making reduces production time by eliminating the wait between layers, allowing for faster batch completion and lower labor costs. Double pour methods increase material expenses due to the need for multiple wax batches and extend production time because each layer requires cooling and curing before the next pour. Choosing single pour optimizes cost efficiency and accelerates turnaround, while double pour offers design versatility at the expense of increased time and cost.

Expert Tips for Successful Candle Pouring Techniques

Mastering candle making requires understanding the differences between single pour and double pour techniques to achieve flawless finishes. Single pour involves pouring the entire wax at once, ideal for smaller batches or simple designs, while double pour allows layering for complex aesthetics and enhanced scent diffusion. Expert tips include monitoring wax temperature closely, pouring at recommended temperatures (typically 130-140degF for soy wax), and allowing sufficient cooling time between pours to prevent cracking and uneven surfaces.

Single pour vs Double pour Infographic

bizdif.com

bizdif.com