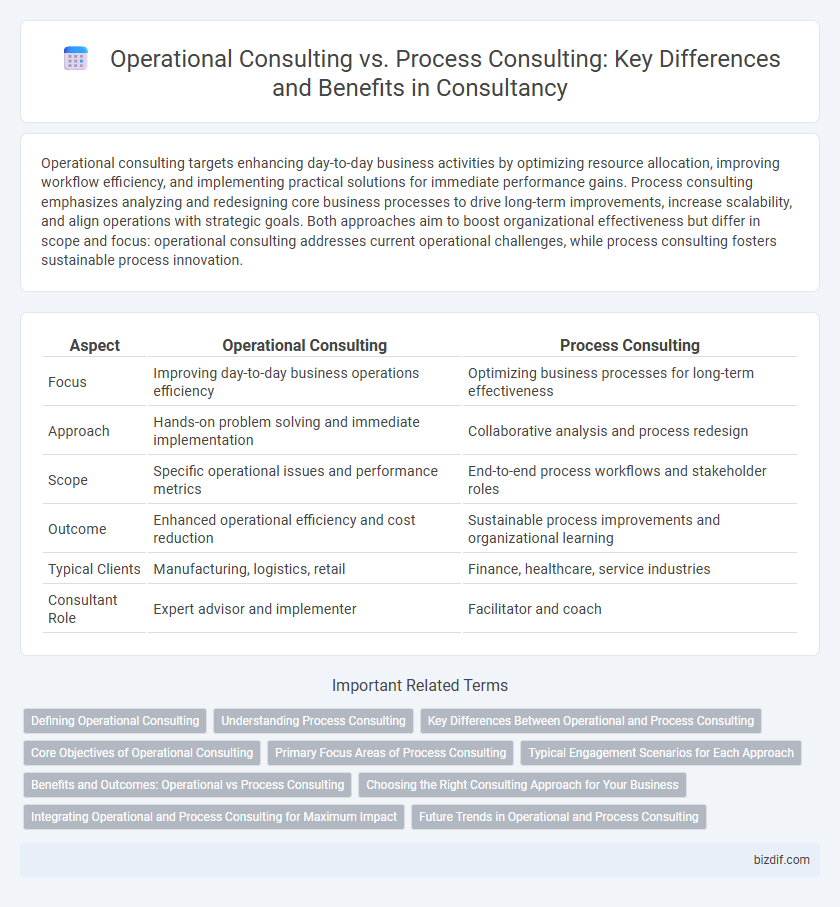

Operational consulting targets enhancing day-to-day business activities by optimizing resource allocation, improving workflow efficiency, and implementing practical solutions for immediate performance gains. Process consulting emphasizes analyzing and redesigning core business processes to drive long-term improvements, increase scalability, and align operations with strategic goals. Both approaches aim to boost organizational effectiveness but differ in scope and focus: operational consulting addresses current operational challenges, while process consulting fosters sustainable process innovation.

Table of Comparison

| Aspect | Operational Consulting | Process Consulting |

|---|---|---|

| Focus | Improving day-to-day business operations efficiency | Optimizing business processes for long-term effectiveness |

| Approach | Hands-on problem solving and immediate implementation | Collaborative analysis and process redesign |

| Scope | Specific operational issues and performance metrics | End-to-end process workflows and stakeholder roles |

| Outcome | Enhanced operational efficiency and cost reduction | Sustainable process improvements and organizational learning |

| Typical Clients | Manufacturing, logistics, retail | Finance, healthcare, service industries |

| Consultant Role | Expert advisor and implementer | Facilitator and coach |

Defining Operational Consulting

Operational consulting focuses on optimizing day-to-day business functions to enhance efficiency, reduce costs, and improve overall performance within an organization's operational framework. This approach involves analyzing workflows, resource allocation, and operational bottlenecks to implement practical solutions that drive measurable improvements. Emphasis is placed on tactical execution and aligning operations with strategic business goals to ensure sustainable growth and competitive advantage.

Understanding Process Consulting

Process Consulting emphasizes gaining deep insights into an organization's workflows and identifying inefficiencies through collaborative analysis with clients. Unlike Operational Consulting, which often prescribes specific solutions and improvements, Process Consulting facilitates client-driven problem-solving by enhancing understanding and ownership of processes. This approach prioritizes sustainable change by aligning processes with strategic goals and empowering internal teams to optimize performance.

Key Differences Between Operational and Process Consulting

Operational consulting focuses on improving overall business performance by identifying inefficiencies in daily operations, resource allocation, and management strategies. Process consulting concentrates specifically on analyzing and redesigning workflows, aiming to enhance process efficiency, reduce waste, and improve quality control. Key differences include the broader scope of operational consulting compared to the targeted, process-specific approach of process consulting, which typically involves detailed mapping and optimization of business processes.

Core Objectives of Operational Consulting

Operational consulting targets enhancing business performance by optimizing resource allocation, improving operational efficiency, and driving cost reduction across core functions. It focuses on implementing strategic initiatives that align with organizational goals, including streamlining workflows, leveraging technology integration, and improving supply chain management. Process consulting, in contrast, centers on analyzing and redesigning specific processes to boost productivity and quality within defined operational areas.

Primary Focus Areas of Process Consulting

Process consulting primarily focuses on analyzing and improving internal workflows, communication channels, and decision-making processes within an organization to enhance operational efficiency and employee collaboration. It emphasizes facilitating change through guided discovery and support rather than providing direct solutions, enabling teams to identify root causes and develop sustainable improvements. Key areas include process mapping, stakeholder engagement, and continuous feedback loops to optimize performance and adaptability.

Typical Engagement Scenarios for Each Approach

Operational consulting typically involves engagements centered on improving day-to-day business functions, such as supply chain optimization, cost reduction strategies, and performance management to enhance efficiency and productivity. Process consulting focuses on redesigning and streamlining workflows, business processes, and organizational procedures, often through mapping, analysis, and implementation of process improvements to drive long-term adaptability. Typical scenarios for operational consulting include tackling immediate operational challenges and turnaround strategies, whereas process consulting is engaged during digital transformation initiatives, process automation projects, and quality management system enhancements.

Benefits and Outcomes: Operational vs Process Consulting

Operational consulting drives improvements in organizational efficiency by optimizing resource allocation and enhancing workforce productivity, leading to measurable cost reductions and faster project delivery. Process consulting focuses on refining business workflows and systematizing procedures, which fosters consistency, reduces errors, and improves quality control across departments. Combining both approaches results in synergistic benefits, including streamlined operations, higher customer satisfaction, and sustained competitive advantage.

Choosing the Right Consulting Approach for Your Business

Operational consulting focuses on improving a company's day-to-day activities and resource management to enhance efficiency and productivity. Process consulting emphasizes analyzing and redesigning business workflows and procedures to optimize performance and reduce bottlenecks. Selecting the right consulting approach depends on your business goals: operational consulting suits immediate operational improvements, while process consulting is ideal for long-term strategic process enhancements.

Integrating Operational and Process Consulting for Maximum Impact

Integrating operational consulting and process consulting enhances organizational performance by aligning strategic initiatives with efficient workflows and resource management. Operational consulting focuses on optimizing overall business functions and performance metrics, while process consulting targets specific procedural improvements and workflow refinements. Combining these approaches ensures a holistic transformation, driving sustainable growth, operational agility, and increased competitive advantage.

Future Trends in Operational and Process Consulting

Emerging future trends in operational and process consulting emphasize the integration of artificial intelligence and automation to enhance efficiency and decision-making accuracy. Data-driven insights are increasingly leveraged to customize solutions for complex business challenges, driving sustainable operational improvements. Consultants are also focusing on agile methodologies and real-time process optimization to adapt to rapidly evolving market demands.

Operational Consulting vs Process Consulting Infographic

bizdif.com

bizdif.com