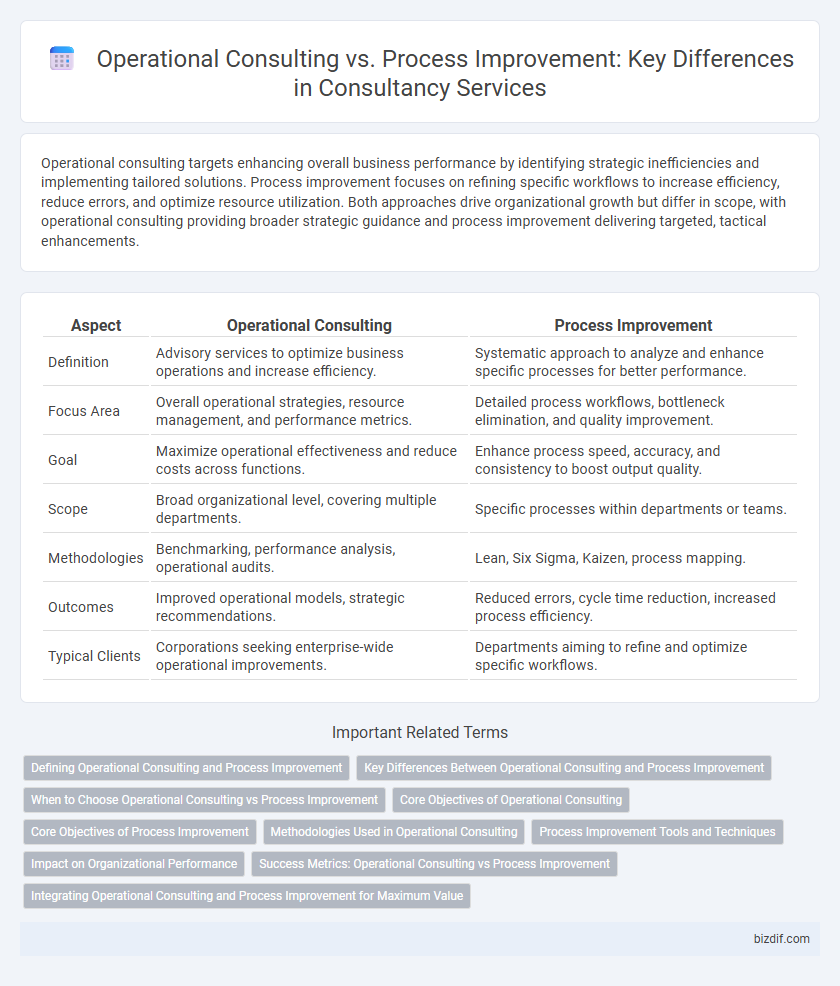

Operational consulting targets enhancing overall business performance by identifying strategic inefficiencies and implementing tailored solutions. Process improvement focuses on refining specific workflows to increase efficiency, reduce errors, and optimize resource utilization. Both approaches drive organizational growth but differ in scope, with operational consulting providing broader strategic guidance and process improvement delivering targeted, tactical enhancements.

Table of Comparison

| Aspect | Operational Consulting | Process Improvement |

|---|---|---|

| Definition | Advisory services to optimize business operations and increase efficiency. | Systematic approach to analyze and enhance specific processes for better performance. |

| Focus Area | Overall operational strategies, resource management, and performance metrics. | Detailed process workflows, bottleneck elimination, and quality improvement. |

| Goal | Maximize operational effectiveness and reduce costs across functions. | Enhance process speed, accuracy, and consistency to boost output quality. |

| Scope | Broad organizational level, covering multiple departments. | Specific processes within departments or teams. |

| Methodologies | Benchmarking, performance analysis, operational audits. | Lean, Six Sigma, Kaizen, process mapping. |

| Outcomes | Improved operational models, strategic recommendations. | Reduced errors, cycle time reduction, increased process efficiency. |

| Typical Clients | Corporations seeking enterprise-wide operational improvements. | Departments aiming to refine and optimize specific workflows. |

Defining Operational Consulting and Process Improvement

Operational consulting involves analyzing and optimizing an organization's overall business operations to enhance efficiency, reduce costs, and improve performance across departments. Process improvement focuses specifically on identifying, diagnosing, and refining individual workflows or procedures to eliminate bottlenecks and increase productivity. Both approaches prioritize systematic evaluation and restructuring but differ in scope, with operational consulting targeting broad organizational strategies and process improvement honing in on specific operational tasks.

Key Differences Between Operational Consulting and Process Improvement

Operational consulting focuses on analyzing and optimizing the overall business operations to enhance efficiency, productivity, and profitability across departments. Process improvement targets specific workflows or processes within an organization to eliminate waste, reduce cycle times, and improve quality using methodologies like Lean and Six Sigma. Key differences lie in scope, with operational consulting addressing broader organizational changes and strategy, while process improvement concentrates on detailed, incremental enhancements within existing processes.

When to Choose Operational Consulting vs Process Improvement

Choose operational consulting when organizations face strategic challenges that require expert guidance to optimize overall business performance and align operations with long-term goals. Process improvement is best suited for organizations aiming to enhance specific workflows, increase efficiency, and reduce costs through targeted analysis and refinement of existing processes. Selecting the right approach depends on whether the focus is on broad operational transformation or incremental enhancements within defined processes.

Core Objectives of Operational Consulting

Operational consulting focuses on enhancing business performance by optimizing core operational functions such as supply chain management, production efficiency, and resource allocation. The core objectives involve identifying bottlenecks, reducing operational costs, and implementing scalable solutions that align with strategic goals. Unlike broader process improvement initiatives, operational consulting emphasizes actionable strategies that drive measurable improvements in day-to-day business operations.

Core Objectives of Process Improvement

Process Improvement centers on enhancing efficiency, quality, and consistency within existing workflows to reduce waste and increase customer satisfaction. It targets identifying bottlenecks, eliminating redundant steps, and standardizing processes to optimize resource utilization. Operational Consulting often incorporates these process optimizations but emphasizes broader strategic alignment and organizational change management.

Methodologies Used in Operational Consulting

Operational consulting utilizes methodologies such as Lean Six Sigma, Agile frameworks, and Business Process Management (BPM) to optimize organizational efficiency and performance. These approaches emphasize data-driven analysis, continuous improvement, and cross-functional collaboration to identify bottlenecks and implement scalable solutions. Process improvement focuses specifically on refining existing workflows, while operational consulting integrates broader strategic insights with these methodologies to enhance overall business operations.

Process Improvement Tools and Techniques

Process Improvement in consultancy leverages specialized tools and techniques such as Lean, Six Sigma, and Kaizen to enhance operational efficiency and reduce waste. These methodologies utilize data-driven approaches like DMAIC (Define, Measure, Analyze, Improve, Control) and value stream mapping to identify bottlenecks and optimize workflows. Unlike broader Operational Consulting, which may address strategic and organizational changes, Process Improvement focuses specifically on refining internal processes to achieve measurable performance improvements.

Impact on Organizational Performance

Operational consulting drives organizational performance by aligning business strategies with operational capabilities, enhancing resource allocation, and optimizing workflows to achieve measurable efficiency gains. Process improvement focuses specifically on analyzing and refining individual processes, reducing waste, and increasing productivity, thereby delivering targeted enhancements within specific operational areas. Together, these approaches contribute to sustained performance improvement by blending strategic operational changes with granular process optimizations.

Success Metrics: Operational Consulting vs Process Improvement

Operational consulting success metrics often focus on key performance indicators (KPIs) such as return on investment (ROI), cost reduction, and operational efficiency gains. Process improvement success is typically measured by cycle time reduction, error rate decrease, and enhanced process throughput. Both approaches rely on quantitative data analysis but prioritize different metrics aligned with strategic versus tactical objectives.

Integrating Operational Consulting and Process Improvement for Maximum Value

Integrating operational consulting with process improvement drives transformational business outcomes by aligning strategic goals with efficient workflows. Operational consulting identifies overarching challenges and designs tailored strategies, while process improvement refines specific activities to enhance productivity and reduce waste. Leveraging both approaches ensures holistic optimization, maximizing value through sustained performance enhancements and scalable solutions.

Operational Consulting vs Process Improvement Infographic

bizdif.com

bizdif.com