Direct shipping in dropshipping pet products allows sellers to reduce upfront costs and avoid inventory management by having suppliers ship items directly to customers. Inventory holding offers faster delivery times and greater control over product quality, enhancing customer satisfaction and brand reputation. Choosing between these methods depends on balancing operational control with flexibility and financial investment.

Table of Comparison

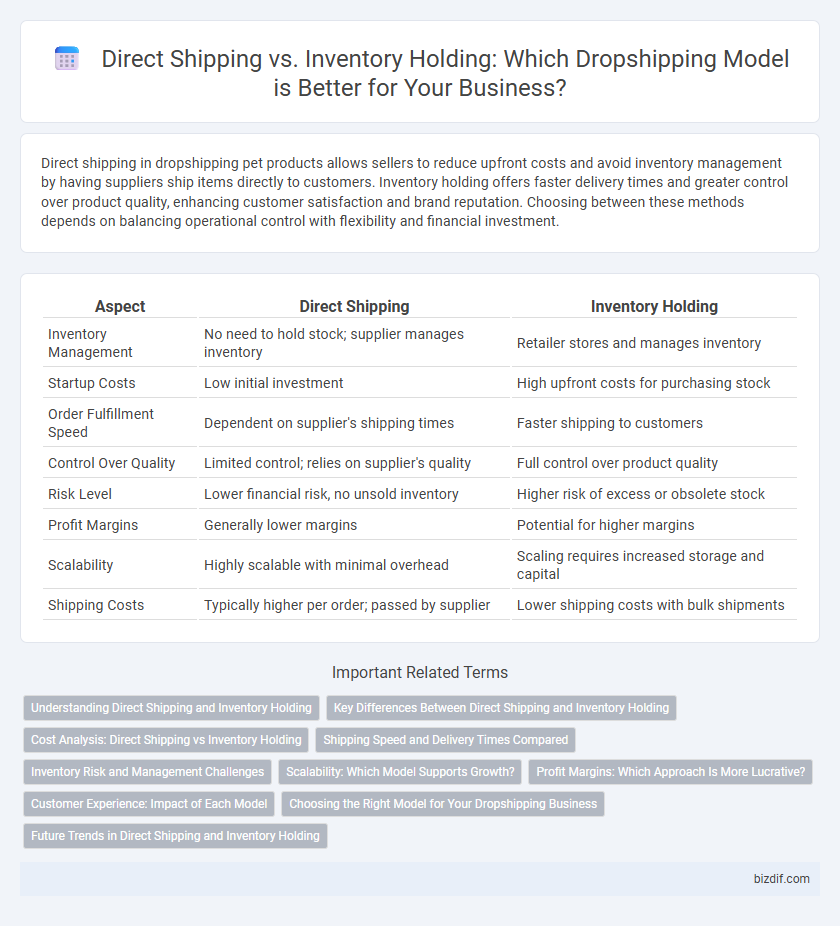

| Aspect | Direct Shipping | Inventory Holding |

|---|---|---|

| Inventory Management | No need to hold stock; supplier manages inventory | Retailer stores and manages inventory |

| Startup Costs | Low initial investment | High upfront costs for purchasing stock |

| Order Fulfillment Speed | Dependent on supplier's shipping times | Faster shipping to customers |

| Control Over Quality | Limited control; relies on supplier's quality | Full control over product quality |

| Risk Level | Lower financial risk, no unsold inventory | Higher risk of excess or obsolete stock |

| Profit Margins | Generally lower margins | Potential for higher margins |

| Scalability | Highly scalable with minimal overhead | Scaling requires increased storage and capital |

| Shipping Costs | Typically higher per order; passed by supplier | Lower shipping costs with bulk shipments |

Understanding Direct Shipping and Inventory Holding

Direct shipping in dropshipping involves suppliers shipping products directly to customers, eliminating the need for sellers to maintain inventory, which reduces upfront costs and storage risks. Inventory holding requires sellers to purchase and store products, allowing for faster order fulfillment and greater control over quality and packaging. Understanding the trade-offs between direct shipping and inventory holding is crucial for optimizing supply chain efficiency and customer satisfaction in e-commerce.

Key Differences Between Direct Shipping and Inventory Holding

Direct shipping involves sending products directly from suppliers to customers, minimizing storage costs and reducing delivery times, whereas inventory holding requires maintaining stock in warehouses, which increases overhead expenses but allows faster order fulfillment. Inventory holding provides greater control over product quality and packaging, while direct shipping often relies on third-party suppliers, potentially impacting consistency and customer experience. Choosing between these models depends on factors like cash flow, scalability, shipping speed, and inventory management capabilities.

Cost Analysis: Direct Shipping vs Inventory Holding

Direct shipping eliminates the need for warehousing costs, reducing upfront investment and lowering financial risk compared to inventory holding, which requires capital tied up in stock and storage fees. Inventory holding can offer faster delivery times and bulk purchasing discounts but increases costs through inventory management, potential obsolescence, and spoilage. Analyzing cost structures reveals direct shipping as a lean model ideal for limited budgets, while inventory holding benefits businesses with high sales volume and demand predictability.

Shipping Speed and Delivery Times Compared

Direct shipping typically offers faster delivery times since products are sent directly from suppliers to customers, bypassing the need for inventory storage and handling. Inventory holding involves pre-stocking items, which can shorten shipping times if products are stored close to the customer, but may lead to delays if inventory management is inefficient. Shipping speed in dropshipping heavily depends on supplier location and logistics, whereas inventory holding relies on warehouse proximity and stock levels.

Inventory Risk and Management Challenges

Direct shipping minimizes inventory risk by eliminating the need to store products, reducing upfront costs and unsold stock liabilities. In contrast, inventory holding requires significant investment in warehousing, exposes sellers to stock obsolescence, and demands complex inventory management systems to track and replenish products efficiently. Businesses must weigh the trade-offs between operational control in inventory holding and the lower financial risk offered by direct shipping models.

Scalability: Which Model Supports Growth?

Direct shipping offers superior scalability by eliminating the need for upfront inventory investment, allowing businesses to quickly expand product offerings and enter new markets with minimal risk. Inventory holding requires significant capital and storage space, limiting the ability to rapidly scale operations due to stock management and increased overhead costs. Therefore, dropshipping supports faster and more flexible growth compared to traditional inventory-holding models.

Profit Margins: Which Approach Is More Lucrative?

Direct shipping offers lower upfront costs by eliminating inventory expenses, leading to higher profit margins per sale despite thinner individual markups. Inventory holding demands significant capital for stock but enables bulk purchasing discounts and better control over pricing, often resulting in stronger overall profit margins. Evaluating product demand consistency and supplier reliability is crucial to determining which approach yields greater profitability for a specific dropshipping business.

Customer Experience: Impact of Each Model

Direct shipping offers faster delivery times and real-time order tracking, enhancing customer satisfaction through prompt service. Inventory holding allows better quality control and faster response to returns or exchanges, boosting reliability. Customers typically value speedy delivery and accurate order fulfillment, making the choice between models pivotal for optimized user experience in dropshipping.

Choosing the Right Model for Your Dropshipping Business

Selecting the appropriate dropshipping model hinges on factors like capital investment, control over inventory, and fulfillment speed. Direct shipping minimizes upfront costs and storage responsibilities by sending products directly from suppliers to customers, optimizing cash flow but potentially extending delivery times. Inventory holding demands higher initial investment and storage management but enhances product availability and shipping speed, catering to businesses aiming for quicker customer satisfaction and brand control.

Future Trends in Direct Shipping and Inventory Holding

Future trends in direct shipping emphasize faster delivery times through advanced logistics technology, increased automation, and AI-driven inventory management to minimize delays and reduce costs. Inventory holding is evolving with hybrid fulfillment models, integrating localized warehouses and real-time stock tracking to balance customer demand and supply chain flexibility. Both models are leveraging sustainable packaging and eco-friendly practices to meet growing consumer expectations for environmental responsibility in dropshipping.

Direct Shipping vs Inventory Holding Infographic

bizdif.com

bizdif.com