Inventory holding in dropshipping pet businesses allows sellers to maintain stock of popular pet products, ensuring faster shipping and better control over quality but requires upfront investment and storage space. Zero inventory dropshipping eliminates the need for warehousing by directly sourcing products from suppliers after orders are placed, reducing financial risk and overhead costs. Choosing between these methods depends on balancing speed, control, and capital availability for pet product sellers.

Table of Comparison

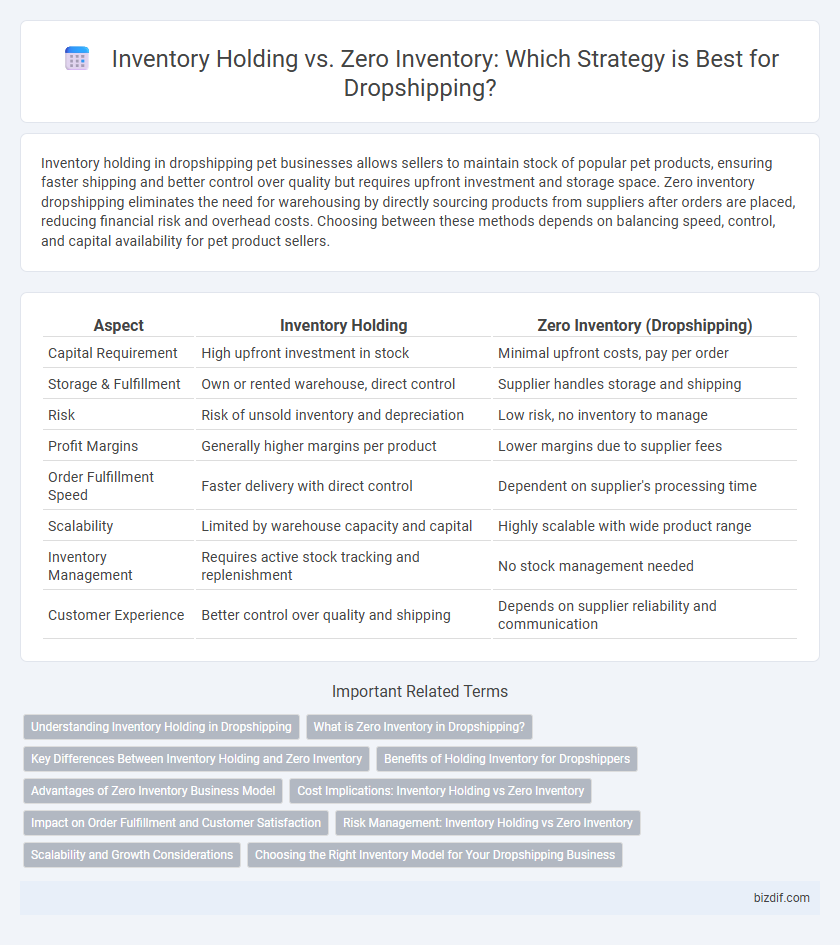

| Aspect | Inventory Holding | Zero Inventory (Dropshipping) |

|---|---|---|

| Capital Requirement | High upfront investment in stock | Minimal upfront costs, pay per order |

| Storage & Fulfillment | Own or rented warehouse, direct control | Supplier handles storage and shipping |

| Risk | Risk of unsold inventory and depreciation | Low risk, no inventory to manage |

| Profit Margins | Generally higher margins per product | Lower margins due to supplier fees |

| Order Fulfillment Speed | Faster delivery with direct control | Dependent on supplier's processing time |

| Scalability | Limited by warehouse capacity and capital | Highly scalable with wide product range |

| Inventory Management | Requires active stock tracking and replenishment | No stock management needed |

| Customer Experience | Better control over quality and shipping | Depends on supplier reliability and communication |

Understanding Inventory Holding in Dropshipping

Inventory holding in dropshipping requires merchants to maintain a stock of products, allowing faster shipping and better quality control compared to zero inventory models. Managing inventory holding demands investment in warehousing, order fulfillment processes, and accurate demand forecasting to prevent overstock or stockouts. This approach can enhance customer satisfaction through reliable availability but increases operational complexity and upfront costs.

What is Zero Inventory in Dropshipping?

Zero inventory in dropshipping refers to a business model where sellers do not store any products physically; instead, they forward customer orders directly to suppliers, who then ship items straight to the buyers. This approach eliminates the need for inventory holding, significantly reducing upfront costs and risks related to unsold stock. Dropshipping platforms like Shopify and Oberlo support zero inventory by integrating supplier catalogs with online stores, enabling seamless order fulfillment without inventory management.

Key Differences Between Inventory Holding and Zero Inventory

Inventory holding involves maintaining physical stock in warehouses, enabling faster shipping times and control over product quality but requires upfront investment and storage costs. Zero inventory, typical in dropshipping, eliminates the need for stock management by relying on suppliers to ship directly to customers, reducing overhead but potentially increasing delivery times and dependence on suppliers. The key differences lie in inventory risk, capital commitment, and fulfillment control, influencing business scalability and customer experience.

Benefits of Holding Inventory for Dropshippers

Holding inventory in dropshipping enables faster order fulfillment and enhances customer satisfaction by reducing delivery times. Maintaining stock allows better quality control and accurate product availability, minimizing the risk of cancellations and returns. Bulk purchasing through inventory holding also lowers per-unit costs, increasing profit margins for dropshippers.

Advantages of Zero Inventory Business Model

Zero inventory dropshipping eliminates the need for upfront stock investment, significantly reducing financial risk and storage costs. This model offers greater flexibility to test and expand product offerings without the constraints of physical inventory management. Faster scalability and streamlined operations enhance cash flow and improve the overall business agility in competitive markets.

Cost Implications: Inventory Holding vs Zero Inventory

Inventory holding in dropshipping increases costs through warehousing fees, stock depreciation, and capital tied up in unsold products, impacting cash flow and profitability. Zero inventory dropshipping eliminates storage expenses and reduces financial risk by purchasing products only after customer orders, improving cost-efficiency. Evaluating these cost implications helps businesses optimize operating expenses and maintain healthier profit margins.

Impact on Order Fulfillment and Customer Satisfaction

Inventory holding allows faster order fulfillment since products are ready to ship, significantly enhancing customer satisfaction through reduced delivery times and reliable stock availability. Zero inventory, common in dropshipping, relies heavily on supplier efficiency, which can lead to delays and stockouts, potentially lowering customer satisfaction. Effective communication and supplier partnerships are crucial to mitigate fulfillment issues in zero inventory models and maintain positive customer experiences.

Risk Management: Inventory Holding vs Zero Inventory

Inventory holding exposes dropshipping businesses to risks such as overstock, obsolescence, and high warehousing costs, which can lead to increased financial loss and reduced cash flow. Zero inventory models minimize these risks by eliminating stock-related expenses and enabling real-time order fulfillment directly from suppliers, enhancing flexibility and reducing capital tied up in products. Effective risk management in dropshipping involves balancing inventory holding's control over stock availability against zero inventory's agility and cost-efficiency.

Scalability and Growth Considerations

Dropshipping's zero inventory model enables rapid scalability by eliminating the need for upfront stock investment, reducing financial risk and allowing businesses to quickly test and expand product offerings. In contrast, inventory holding requires significant capital and storage resources, potentially limiting growth speed but offering better control over product quality and shipping times. For scalable growth, zero inventory models thrive on flexible supplier networks and efficient order fulfillment systems.

Choosing the Right Inventory Model for Your Dropshipping Business

Choosing the right inventory model for your dropshipping business significantly impacts cash flow and operational efficiency. Inventory holding requires upfront investment and storage management but offers faster shipping and better quality control, while zero inventory relies on supplier stock, minimizing costs and risks but may face longer delivery times and less control over product availability. Evaluate factors like capital availability, supplier reliability, and customer expectations to optimize your inventory strategy for profitability and scalability.

Inventory Holding vs Zero Inventory Infographic

bizdif.com

bizdif.com