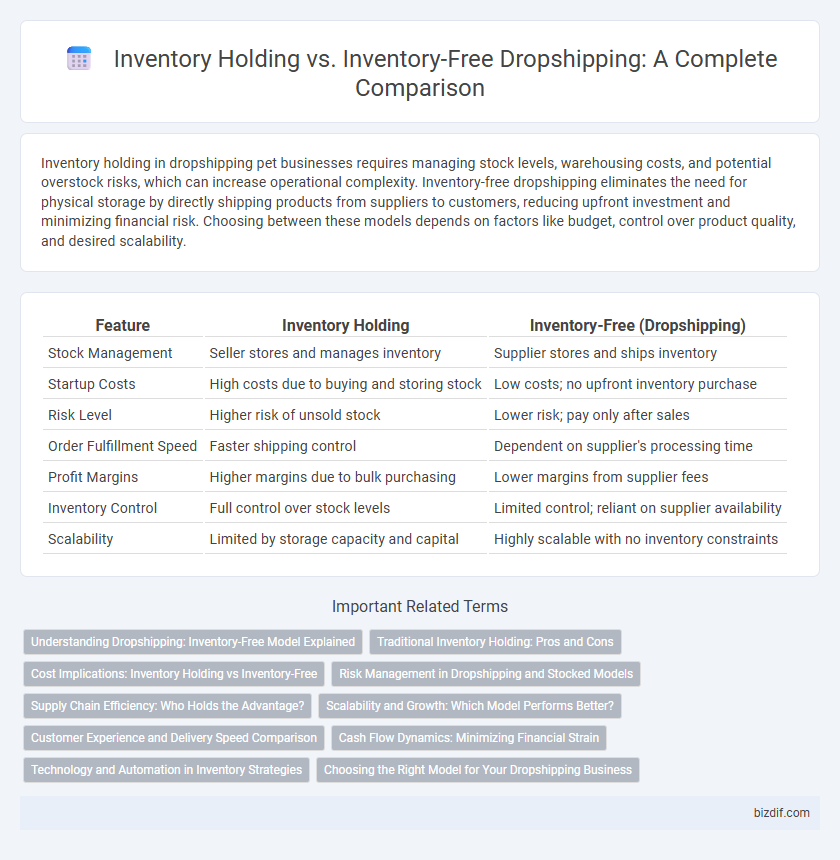

Inventory holding in dropshipping pet businesses requires managing stock levels, warehousing costs, and potential overstock risks, which can increase operational complexity. Inventory-free dropshipping eliminates the need for physical storage by directly shipping products from suppliers to customers, reducing upfront investment and minimizing financial risk. Choosing between these models depends on factors like budget, control over product quality, and desired scalability.

Table of Comparison

| Feature | Inventory Holding | Inventory-Free (Dropshipping) |

|---|---|---|

| Stock Management | Seller stores and manages inventory | Supplier stores and ships inventory |

| Startup Costs | High costs due to buying and storing stock | Low costs; no upfront inventory purchase |

| Risk Level | Higher risk of unsold stock | Lower risk; pay only after sales |

| Order Fulfillment Speed | Faster shipping control | Dependent on supplier's processing time |

| Profit Margins | Higher margins due to bulk purchasing | Lower margins from supplier fees |

| Inventory Control | Full control over stock levels | Limited control; reliant on supplier availability |

| Scalability | Limited by storage capacity and capital | Highly scalable with no inventory constraints |

Understanding Dropshipping: Inventory-Free Model Explained

The inventory-free model in dropshipping eliminates the need for sellers to stock products, reducing upfront costs and minimizing risk by directly shipping items from suppliers to customers. This approach streamlines operations, allowing entrepreneurs to focus on marketing and customer acquisition without managing warehouse logistics. Understanding this model is key to leveraging supplier partnerships and optimizing supply chain efficiency in dropshipping businesses.

Traditional Inventory Holding: Pros and Cons

Traditional inventory holding in dropshipping involves purchasing and storing products upfront, allowing sellers to manage stock levels and fulfill orders quickly. This model offers benefits such as better control over product quality and faster shipping times, but it also carries risks like higher upfront costs, potential overstock, and the need for warehousing space. Managing inventory effectively is crucial to minimizing losses and maintaining profitability in this approach.

Cost Implications: Inventory Holding vs Inventory-Free

Inventory holding in dropshipping incurs costs such as warehousing, insurance, and risk of unsold stock, which can significantly impact overall profitability. Inventory-free models eliminate these expenses by shipping directly from suppliers to customers, reducing upfront investment and minimizing financial risk. However, inventory-free may face higher per-unit costs and less control over stock availability, influencing pricing strategies and profit margins.

Risk Management in Dropshipping and Stocked Models

Dropshipping minimizes financial risk by eliminating the need for inventory holding, allowing retailers to sell products without upfront stock investment, thus reducing losses from unsold items. Inventory-free models rely heavily on supplier reliability and efficient order fulfillment to maintain customer satisfaction and avoid stockouts or delays. In contrast, stocked models require significant capital for inventory management, increasing the risk of overstocking and obsolescence but providing greater control over product availability and shipping speed.

Supply Chain Efficiency: Who Holds the Advantage?

Inventory-free dropshipping eliminates the need for warehousing, reducing overhead costs and enabling faster response to market demand fluctuations. Inventory holding allows for greater control over stock quality and faster shipping times, which can enhance customer satisfaction and reduce return rates. Supply chain efficiency depends on a business's ability to balance inventory costs with order fulfillment speed, with inventory-free models excelling in flexibility and inventory holding models in reliability.

Scalability and Growth: Which Model Performs Better?

Inventory-free dropshipping offers superior scalability by eliminating the need for upfront stock investment, allowing businesses to quickly expand product offerings without increased overhead. Inventory-holding models face growth limitations due to storage costs, inventory management, and increased risk of unsold products. Companies seeking rapid market entry and flexible scaling typically achieve faster growth with inventory-free approaches.

Customer Experience and Delivery Speed Comparison

Inventory-free dropshipping enhances customer experience by offering a wide product selection without storage limitations, but delivery speed can be slower due to supplier processing and shipping times. Inventory holding allows merchants to control stock levels, resulting in faster order fulfillment and improved delivery reliability, which directly benefits customer satisfaction. Balancing inventory strategies is crucial to optimize both product availability and prompt delivery in the competitive dropshipping market.

Cash Flow Dynamics: Minimizing Financial Strain

Inventory-free dropshipping significantly improves cash flow dynamics by eliminating the need for upfront inventory purchases, reducing financial risk and strain. Without holding stock, businesses avoid tying up capital in unsold products, enabling faster liquidity turnover and operational flexibility. This model supports scalable growth while maintaining minimal overhead costs, critical for sustaining healthy cash flow.

Technology and Automation in Inventory Strategies

Inventory-free dropshipping leverages advanced automation tools and real-time data integration to streamline order processing without the need for physical stock, reducing overhead costs and minimizing risk. Technology-powered inventory holding models utilize predictive analytics and inventory management software to optimize stock levels, enhance demand forecasting, and prevent stockouts or overstock situations. Both strategies benefit from cloud-based platforms and API integrations that enable seamless communication between suppliers, warehouses, and e-commerce systems for efficient supply chain execution.

Choosing the Right Model for Your Dropshipping Business

Choosing the right inventory model for your dropshipping business significantly impacts operational efficiency and customer satisfaction. Inventory holding offers control over stock quality and faster shipping times, ideal for high-demand or niche products, while inventory-free approaches minimize upfront costs and reduce financial risk by relying on suppliers to manage stock and fulfillment. Evaluating factors like order volume, supplier reliability, and cash flow helps determine whether an inventory holding or inventory-free model aligns best with your business goals.

Inventory Holding vs Inventory-Free Infographic

bizdif.com

bizdif.com