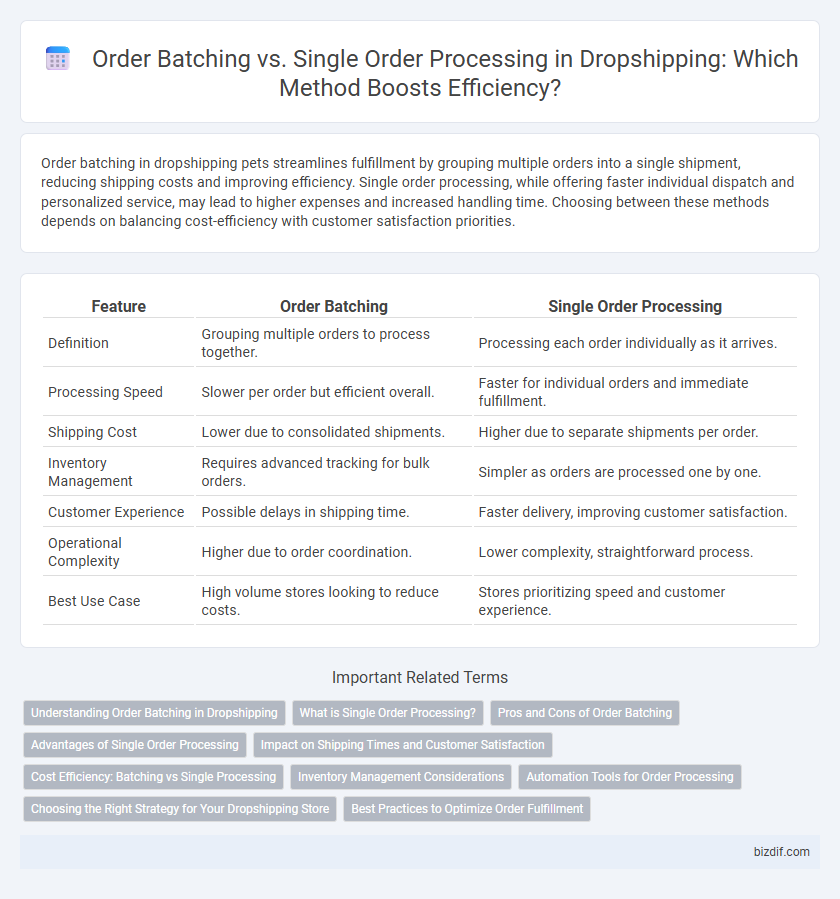

Order batching in dropshipping pets streamlines fulfillment by grouping multiple orders into a single shipment, reducing shipping costs and improving efficiency. Single order processing, while offering faster individual dispatch and personalized service, may lead to higher expenses and increased handling time. Choosing between these methods depends on balancing cost-efficiency with customer satisfaction priorities.

Table of Comparison

| Feature | Order Batching | Single Order Processing |

|---|---|---|

| Definition | Grouping multiple orders to process together. | Processing each order individually as it arrives. |

| Processing Speed | Slower per order but efficient overall. | Faster for individual orders and immediate fulfillment. |

| Shipping Cost | Lower due to consolidated shipments. | Higher due to separate shipments per order. |

| Inventory Management | Requires advanced tracking for bulk orders. | Simpler as orders are processed one by one. |

| Customer Experience | Possible delays in shipping time. | Faster delivery, improving customer satisfaction. |

| Operational Complexity | Higher due to order coordination. | Lower complexity, straightforward process. |

| Best Use Case | High volume stores looking to reduce costs. | Stores prioritizing speed and customer experience. |

Understanding Order Batching in Dropshipping

Order batching in dropshipping consolidates multiple customer orders into a single shipment, reducing shipping costs and streamlining fulfillment. This method improves inventory management by synchronizing stock levels and minimizes packaging waste, leading to higher operational efficiency. Efficient order batching depends on accurate demand forecasting and reliable supplier coordination to prevent delays and maintain customer satisfaction.

What is Single Order Processing?

Single order processing in dropshipping refers to handling and fulfilling each customer order independently, without grouping multiple orders together. This method ensures personalized attention to order details and faster response times per individual purchase, enhancing customer satisfaction. However, it may result in higher shipping costs and longer overall processing times compared to order batching strategies.

Pros and Cons of Order Batching

Order batching in dropshipping consolidates multiple orders for simultaneous processing, reducing shipping costs and improving fulfillment efficiency. This method can lead to faster processing times for bulk shipments but may delay individual order dispatch, potentially affecting customer satisfaction. However, it optimizes inventory management and minimizes packaging waste, balancing cost savings with the risk of slower delivery.

Advantages of Single Order Processing

Single order processing in dropshipping offers faster fulfillment times by handling each order individually, reducing the risk of errors and improving customer satisfaction. This method allows for real-time inventory updates, minimizing stockouts and overselling issues. Enhanced tracking and personalized packaging options create a seamless buying experience that drives repeat business and brand loyalty.

Impact on Shipping Times and Customer Satisfaction

Order batching in dropshipping consolidates multiple orders for simultaneous processing, reducing shipping costs but potentially delaying delivery times compared to single order processing. Single order processing ensures faster shipment dispatch, enhancing customer satisfaction through quicker delivery but may increase shipping expenses. Balancing order batching with timely fulfillment optimizes shipping efficiency while maintaining positive customer experiences.

Cost Efficiency: Batching vs Single Processing

Order batching significantly reduces shipping and handling costs by consolidating multiple orders into one shipment, lowering per-unit expenses and maximizing carrier discounts. Single order processing, while faster for individual shipments, incurs higher cumulative costs due to repeated packaging and shipping fees. For dropshipping businesses aiming to optimize cost efficiency, batching orders offers a strategic advantage by minimizing overhead and enhancing profit margins.

Inventory Management Considerations

Order batching enhances inventory management by consolidating multiple orders into one shipment, reducing stock discrepancies and lowering handling costs, which improves stock accuracy and fulfillment efficiency. Single order processing allows for real-time inventory updates, minimizing the risk of overselling and enabling precise stock level adjustments for each item sold. Efficient inventory management in dropshipping depends on balancing order batching to optimize shipping logistics and single order processing to maintain accurate stock visibility.

Automation Tools for Order Processing

Automation tools for order processing in dropshipping significantly enhance efficiency by enabling order batching, which consolidates multiple orders into a single shipment to reduce costs and improve delivery speed. Single order processing automation offers real-time tracking and personalized customer communication, ensuring accuracy and timely updates for each purchase. Advanced platforms integrate both batching and single order capabilities, optimizing inventory management and streamlining workflow for scalable dropshipping operations.

Choosing the Right Strategy for Your Dropshipping Store

Order batching in dropshipping consolidates multiple customer orders into a single shipment, reducing shipping costs and improving fulfillment efficiency. Single order processing prioritizes speed by shipping each order individually, enhancing customer satisfaction with faster delivery times. Selecting the right strategy depends on product type, customer expectations, and supplier capabilities to balance cost savings and delivery speed effectively.

Best Practices to Optimize Order Fulfillment

Order batching streamlines order fulfillment by grouping multiple orders for simultaneous processing, reducing handling time and shipping costs, while single order processing focuses on immediate individual order shipment to enhance customer satisfaction. Best practices for optimizing order fulfillment include leveraging automation tools to efficiently categorize orders based on destination, product type, or shipping priority, ensuring accurate inventory updates, and balancing batch sizes to minimize delays without compromising delivery speed. Implementing a hybrid approach tailored to product demand and customer expectations maximizes operational efficiency and improves overall order accuracy.

Order Batching vs Single Order Processing Infographic

bizdif.com

bizdif.com