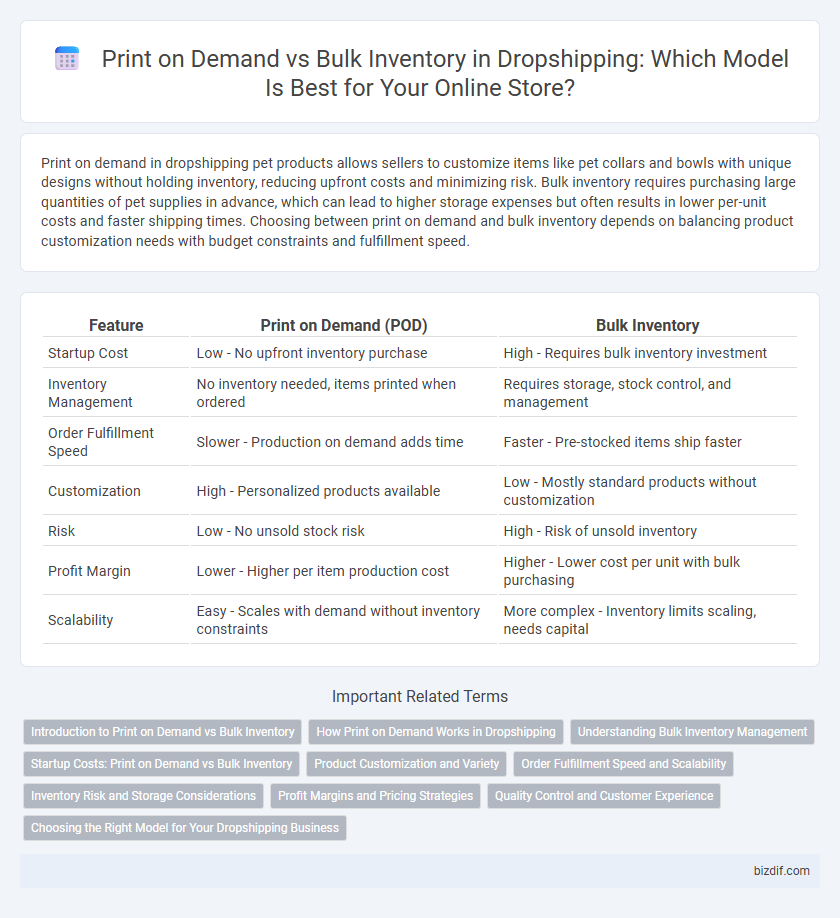

Print on demand in dropshipping pet products allows sellers to customize items like pet collars and bowls with unique designs without holding inventory, reducing upfront costs and minimizing risk. Bulk inventory requires purchasing large quantities of pet supplies in advance, which can lead to higher storage expenses but often results in lower per-unit costs and faster shipping times. Choosing between print on demand and bulk inventory depends on balancing product customization needs with budget constraints and fulfillment speed.

Table of Comparison

| Feature | Print on Demand (POD) | Bulk Inventory |

|---|---|---|

| Startup Cost | Low - No upfront inventory purchase | High - Requires bulk inventory investment |

| Inventory Management | No inventory needed, items printed when ordered | Requires storage, stock control, and management |

| Order Fulfillment Speed | Slower - Production on demand adds time | Faster - Pre-stocked items ship faster |

| Customization | High - Personalized products available | Low - Mostly standard products without customization |

| Risk | Low - No unsold stock risk | High - Risk of unsold inventory |

| Profit Margin | Lower - Higher per item production cost | Higher - Lower cost per unit with bulk purchasing |

| Scalability | Easy - Scales with demand without inventory constraints | More complex - Inventory limits scaling, needs capital |

Introduction to Print on Demand vs Bulk Inventory

Print on Demand (POD) allows entrepreneurs to create customizable products without holding inventory by printing items only after a sale is made, reducing upfront costs and minimizing risk. Bulk Inventory requires purchasing large quantities of products in advance, which leads to higher inventory investment but offers faster shipping times and potentially higher profit margins. Choosing between POD and bulk inventory depends on factors like cash flow, product variety, and scalability goals in a dropshipping business.

How Print on Demand Works in Dropshipping

Print on Demand in dropshipping allows sellers to offer customized products without holding inventory by partnering with suppliers who print and ship items only after receiving customer orders. This model reduces upfront costs and minimizes storage risks by automating order fulfillment directly from the supplier to the customer. It leverages real-time printing technology and seamless integration with e-commerce platforms to ensure efficient processing and delivery.

Understanding Bulk Inventory Management

Bulk inventory management involves purchasing large quantities of products upfront, optimizing storage, and implementing efficient stock tracking systems to reduce costs and avoid stockouts. Properly managed bulk inventory enhances cash flow predictability and ensures faster shipping times compared to print on demand models. Advanced software tools automate reorder points and inventory forecasting, streamlining operations for scalable dropshipping businesses.

Startup Costs: Print on Demand vs Bulk Inventory

Print on Demand requires minimal startup costs since products are only manufactured after a sale is made, eliminating upfront inventory expenses. Bulk Inventory demands significant initial investment to purchase large quantities of stock, increasing financial risk and storage costs. Entrepreneurs seeking low-risk entry often prefer Print on Demand to reduce capital expenditure and inventory management challenges.

Product Customization and Variety

Print on Demand offers extensive product customization options, allowing sellers to create unique designs tailored to niche markets without holding physical inventory, which increases variety and reduces upfront costs. In contrast, Bulk Inventory requires purchasing and storing large quantities of pre-made products, limiting customization but enabling faster shipping and potentially higher profit margins. Choosing between these models depends on the balance between customization flexibility and operational efficiency desired by the dropshipping business.

Order Fulfillment Speed and Scalability

Print on Demand offers faster order fulfillment by printing items only after a customer places an order, eliminating inventory storage and reducing upfront costs. Bulk Inventory involves pre-purchasing stock, which can speed up shipping times but requires significant storage space and higher initial investment. Scalability in Print on Demand is more flexible as it adapts to demand fluctuations without the risk of unsold inventory, whereas Bulk Inventory scalability depends on managing stock levels and warehouse capacity.

Inventory Risk and Storage Considerations

Print on Demand eliminates inventory risk by producing items only after a customer order is placed, reducing storage costs and minimizing unsold stock. Bulk Inventory requires upfront investment in products and warehouse space, increasing the risk of excess or obsolete inventory. Choosing Print on Demand supports leaner business operations with lower financial exposure compared to traditional bulk stock management.

Profit Margins and Pricing Strategies

Print on Demand offers higher profit margins per sale due to its low upfront costs and customized pricing flexibility, though the per-unit cost is typically higher than bulk inventory. Bulk inventory allows for lower product costs through volume discounts, enabling competitive pricing strategies but requires significant initial investment and risk of unsold stock. Effective pricing strategies balance the higher production cost of Print on Demand with niche market targeting, while bulk inventory strategies rely on economies of scale and aggressive pricing to maximize overall profitability.

Quality Control and Customer Experience

Print on Demand offers superior quality control by producing each item individually, reducing defects and allowing for customization that enhances customer satisfaction. Bulk Inventory requires upfront investment and risks overstocking or stockouts, which can compromise product quality and delay shipping times, negatively impacting the customer experience. Prioritizing Print on Demand streamlines inventory management and ensures consistent product standards, fostering stronger brand loyalty.

Choosing the Right Model for Your Dropshipping Business

Print on Demand offers low upfront costs and minimal inventory risk by producing items only after a sale is made, ideal for entrepreneurs testing new designs or niches. Bulk Inventory requires significant upfront investment and storage but enables faster shipping and higher profit margins through economies of scale. Selecting the right dropshipping model depends on balancing cash flow, scalability, and customer expectations for delivery speed.

Print on Demand vs Bulk Inventory Infographic

bizdif.com

bizdif.com