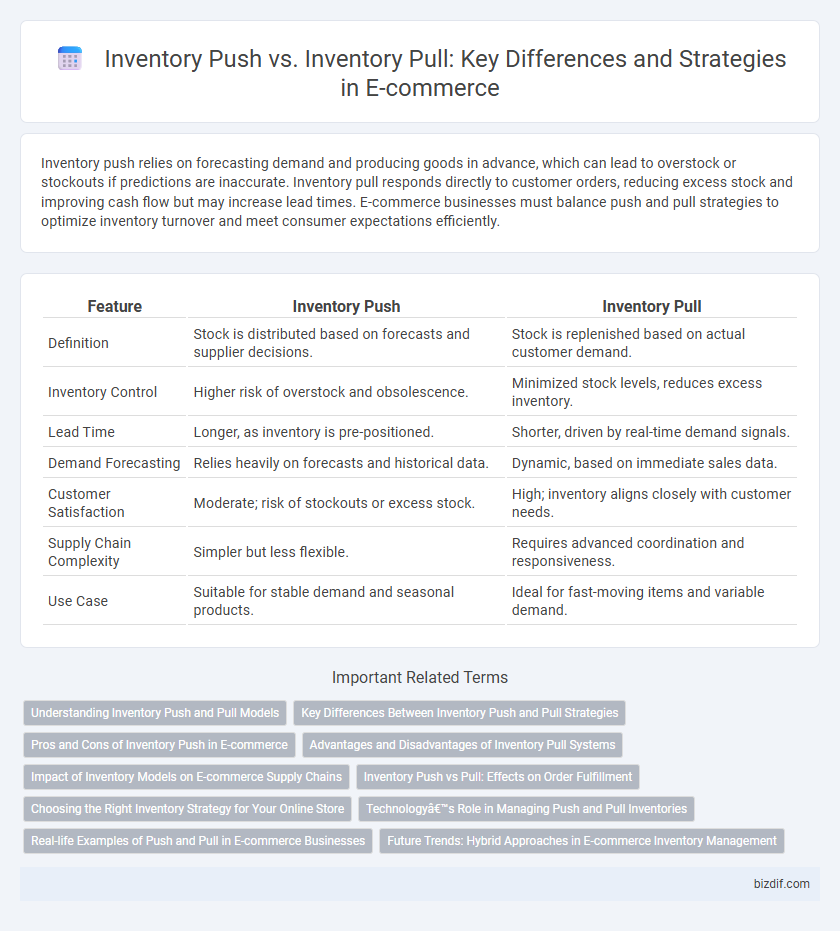

Inventory push relies on forecasting demand and producing goods in advance, which can lead to overstock or stockouts if predictions are inaccurate. Inventory pull responds directly to customer orders, reducing excess stock and improving cash flow but may increase lead times. E-commerce businesses must balance push and pull strategies to optimize inventory turnover and meet consumer expectations efficiently.

Table of Comparison

| Feature | Inventory Push | Inventory Pull |

|---|---|---|

| Definition | Stock is distributed based on forecasts and supplier decisions. | Stock is replenished based on actual customer demand. |

| Inventory Control | Higher risk of overstock and obsolescence. | Minimized stock levels, reduces excess inventory. |

| Lead Time | Longer, as inventory is pre-positioned. | Shorter, driven by real-time demand signals. |

| Demand Forecasting | Relies heavily on forecasts and historical data. | Dynamic, based on immediate sales data. |

| Customer Satisfaction | Moderate; risk of stockouts or excess stock. | High; inventory aligns closely with customer needs. |

| Supply Chain Complexity | Simpler but less flexible. | Requires advanced coordination and responsiveness. |

| Use Case | Suitable for stable demand and seasonal products. | Ideal for fast-moving items and variable demand. |

Understanding Inventory Push and Pull Models

Inventory push and pull models represent two distinct approaches to managing stock in e-commerce. The push model relies on forecasting demand and pushing products to warehouses or stores before customer orders, optimizing bulk inventory availability and reducing lead times. The pull model, driven by real-time customer orders, replenishes inventory only when necessary, minimizing overstock risks and improving cash flow efficiency.

Key Differences Between Inventory Push and Pull Strategies

Inventory Push strategy involves forecasting demand and proactively stocking products based on predicted sales, which can lead to overstock or stockouts if predictions are inaccurate. Inventory Pull strategy relies on actual customer demand to trigger replenishment, minimizing excess inventory but requiring speedy supply chain responsiveness. The key difference lies in demand forecasting versus demand-driven inventory management, impacting cash flow, storage costs, and customer satisfaction in e-commerce operations.

Pros and Cons of Inventory Push in E-commerce

Inventory Push in e-commerce enables proactive stock management by forecasting demand and allocating products to warehouses ahead of time, which reduces delivery times and improves customer satisfaction. However, it carries the risk of overstocking, increased holding costs, and potential obsolescence if demand predictions are inaccurate. This method suits businesses with stable demand patterns but can lead to inefficiencies in highly dynamic markets.

Advantages and Disadvantages of Inventory Pull Systems

Inventory pull systems in e-commerce optimize stock levels by triggering replenishment based on actual customer demand, reducing overstock and minimizing holding costs. These systems enhance responsiveness to market trends, but may increase the risk of stockouts and delays due to reliance on real-time data accuracy and supply chain agility. Effective implementation requires robust demand forecasting tools and seamless supplier coordination to balance inventory availability with cost efficiency.

Impact of Inventory Models on E-commerce Supply Chains

Inventory push models in e-commerce rely on forecasting demand to stock products in advance, resulting in higher carrying costs but improved product availability and faster delivery times. Inventory pull models minimize inventory levels by replenishing stock based on actual customer orders, reducing storage expenses and mitigating overstock risks but potentially increasing lead times. The choice between push and pull inventory strategies significantly influences supply chain responsiveness, cost efficiency, and customer satisfaction in e-commerce operations.

Inventory Push vs Pull: Effects on Order Fulfillment

Inventory push systems maintain stock based on forecasted demand, potentially leading to overstocking or stockouts, which can delay order fulfillment due to excess inventory or lack of products. Inventory pull systems rely on real-time customer orders to trigger replenishment, enhancing order accuracy and reducing storage costs but risking longer lead times if supply chains are slow. Effective order fulfillment in e-commerce depends on balancing push and pull strategies to optimize inventory levels, reduce delivery times, and meet customer expectations consistently.

Choosing the Right Inventory Strategy for Your Online Store

Choosing the right inventory strategy for your online store hinges on balancing demand forecasting and supply chain efficiency. Inventory push relies on proactive stocking based on predicted sales, ideal for products with stable demand, while inventory pull activates replenishment only after customer orders, reducing holding costs and minimizing stockouts for customized or volatile items. Analyzing sales data, customer behavior, and supplier lead times helps online retailers optimize inventory levels and enhance cash flow management.

Technology’s Role in Managing Push and Pull Inventories

Technology enhances inventory management by enabling real-time data analytics and automation, allowing e-commerce businesses to optimize both push and pull inventory strategies. Advanced systems integrate demand forecasting, warehouse management, and supply chain visibility to balance stock levels, reducing overstock and stockouts. Machine learning algorithms further refine inventory decisions by adapting to market trends and customer behavior patterns efficiently.

Real-life Examples of Push and Pull in E-commerce Businesses

Inventory push models in e-commerce involve pre-stocking goods based on demand forecasts, as demonstrated by Amazon's distribution centers which hold large inventories to ensure rapid delivery. Conversely, inventory pull systems rely on real-time customer orders to trigger stock replenishment, exemplified by Zappos, which uses data-driven demand signals to restock shoes only when customers place orders. These strategies balance operational costs and customer satisfaction by aligning inventory management with sales dynamics in the e-commerce sector.

Future Trends: Hybrid Approaches in E-commerce Inventory Management

Emerging hybrid inventory management models combine push and pull strategies to enhance responsiveness and efficiency in e-commerce. Advanced AI algorithms analyze customer demand patterns and supply chain data to dynamically shift inventory allocation between centralized warehouses and decentralized fulfillment centers. This integration aims to reduce stockouts and overstock situations by leveraging real-time data analytics and predictive forecasting in omnichannel retail environments.

Inventory Push vs Inventory Pull Infographic

bizdif.com

bizdif.com