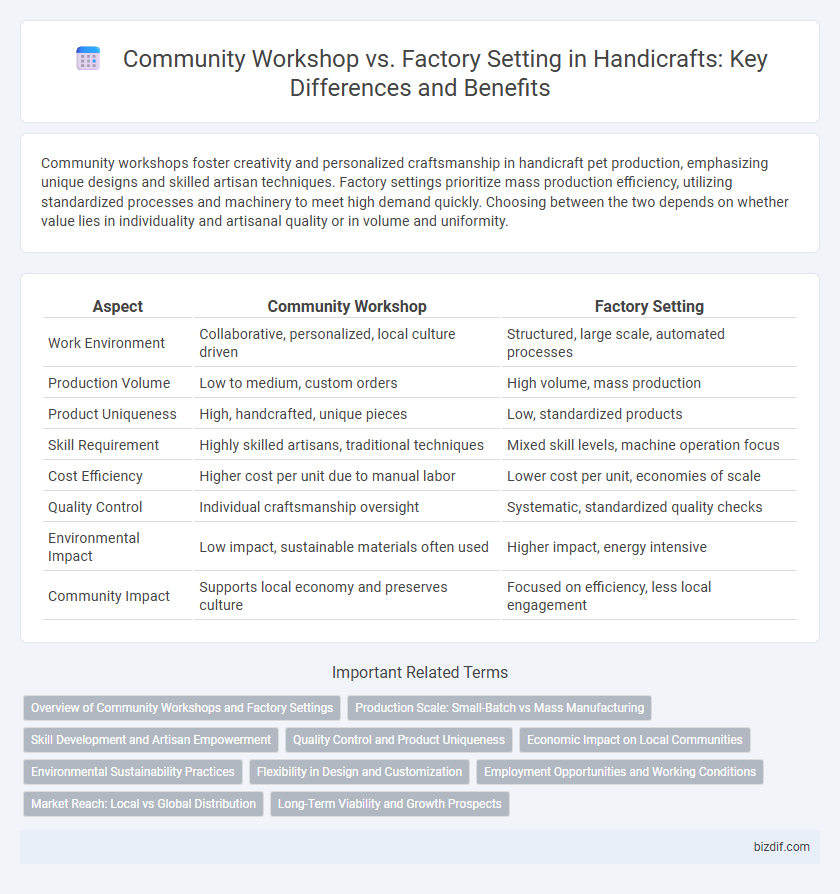

Community workshops foster creativity and personalized craftsmanship in handicraft pet production, emphasizing unique designs and skilled artisan techniques. Factory settings prioritize mass production efficiency, utilizing standardized processes and machinery to meet high demand quickly. Choosing between the two depends on whether value lies in individuality and artisanal quality or in volume and uniformity.

Table of Comparison

| Aspect | Community Workshop | Factory Setting |

|---|---|---|

| Work Environment | Collaborative, personalized, local culture driven | Structured, large scale, automated processes |

| Production Volume | Low to medium, custom orders | High volume, mass production |

| Product Uniqueness | High, handcrafted, unique pieces | Low, standardized products |

| Skill Requirement | Highly skilled artisans, traditional techniques | Mixed skill levels, machine operation focus |

| Cost Efficiency | Higher cost per unit due to manual labor | Lower cost per unit, economies of scale |

| Quality Control | Individual craftsmanship oversight | Systematic, standardized quality checks |

| Environmental Impact | Low impact, sustainable materials often used | Higher impact, energy intensive |

| Community Impact | Supports local economy and preserves culture | Focused on efficiency, less local engagement |

Overview of Community Workshops and Factory Settings

Community workshops emphasize handcrafted techniques, local skill development, and personalized craftsmanship, fostering cultural preservation and sustainable practices. Factory settings prioritize mass production, standardized quality control, and efficiency through mechanization, often resulting in higher output but less uniqueness. The choice between the two impacts product authenticity, social value, and economic scalability in the handicraft industry.

Production Scale: Small-Batch vs Mass Manufacturing

Community workshops specialize in small-batch production, allowing artisans to create unique, high-quality handicrafts with personalized attention to detail. Factory settings prioritize mass manufacturing, utilizing automated processes to produce large quantities efficiently but often sacrificing the individual craftsmanship element. Small-batch production supports creativity and customization, whereas mass manufacturing ensures consistent output and lower per-unit costs.

Skill Development and Artisan Empowerment

Community workshops offer personalized skill development through hands-on training, fostering creativity and mastery in traditional handicraft techniques. They empower artisans by providing a supportive environment for innovation and direct engagement with their craft, enhancing both confidence and economic independence. Factory settings prioritize efficiency and mass production, which often limits opportunities for skill diversification and individual artisan growth.

Quality Control and Product Uniqueness

Community workshops excel in quality control by allowing artisans to meticulously oversee each step, ensuring exceptional craftsmanship and unique product details. Factory settings prioritize mass production efficiency, which can result in uniform but less distinctive items due to automated processes and standardized quality checks. The personalized attention in community workshops fosters innovation and individuality, making each handicraft piece distinct compared to the homogeneity of factory outputs.

Economic Impact on Local Communities

Community workshops in handicraft production generate substantial economic impact by creating local employment opportunities and fostering skill development, which supports small-scale entrepreneurs and preserves cultural heritage. These workshops often circulate income within the community, promoting sustainable economic growth and reducing urban migration. In contrast, factory settings prioritize mass production with limited local economic benefits, as profits frequently flow to external investors and jobs tend to be fewer and less skill-intensive.

Environmental Sustainability Practices

Community workshops in handicraft prioritize sustainable materials, local sourcing, and minimal waste production, significantly reducing their carbon footprint compared to factory settings. Factories often rely on mass production techniques that consume higher energy levels and produce increased emissions, challenging environmental sustainability goals. Emphasizing hands-on craftsmanship in community workshops fosters eco-friendly practices such as recycling scrap materials and utilizing renewable energy sources.

Flexibility in Design and Customization

Community workshops excel in flexibility, allowing artisans to customize designs with intricate, personalized details that reflect individual creativity. Factories prioritize standardized production processes, limiting opportunities for unique customization but ensuring consistent quality and faster output. The adaptability of community workshops supports diverse artistic expressions and bespoke handicraft products tailored to specific customer preferences.

Employment Opportunities and Working Conditions

Community workshops foster inclusive employment opportunities by engaging local artisans in skill development and sustainable craftsmanship, resulting in flexible working conditions tailored to individual needs. Factory settings often provide higher volume job availability but may involve repetitive tasks, regimented schedules, and less personalized work environments. The emphasis on manual dexterity and creative expression in community workshops contrasts with the mechanized, efficiency-driven focus of factories, affecting employee satisfaction and retention.

Market Reach: Local vs Global Distribution

Community workshops excel in crafting unique, handcrafted products that cater to local markets, emphasizing personalized customer experiences and regional cultural significance. Factory settings utilize mass production techniques and advanced logistics systems to achieve expansive global distribution, meeting high-volume demand efficiently. This contrast highlights how community workshops prioritize local authenticity, while factories focus on scalable market reach.

Long-Term Viability and Growth Prospects

Community workshops foster skill retention and cultural heritage, essential for long-term viability in handicraft sectors through personalized craftsmanship and local engagement. Factory settings enable scalable production and consistent quality, supporting growth prospects by meeting market demands efficiently and incorporating advanced technology. Balancing artisanal authenticity with industrial efficiency often determines sustainable expansion and resilience in the handicraft industry.

Community workshop vs Factory setting Infographic

bizdif.com

bizdif.com