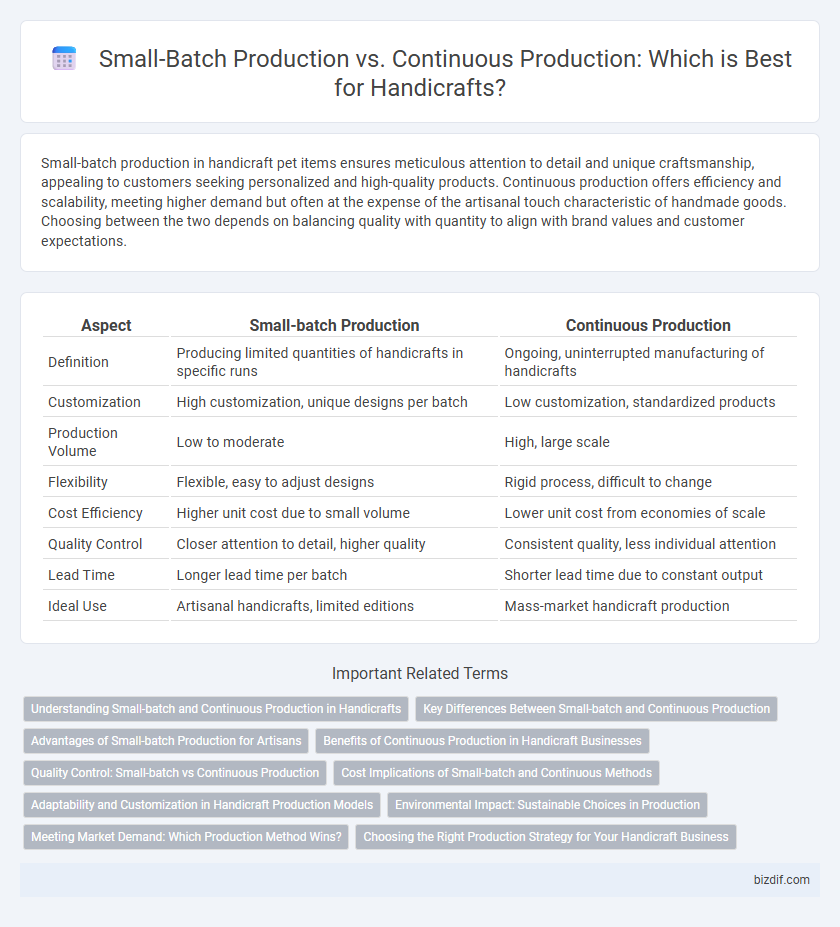

Small-batch production in handicraft pet items ensures meticulous attention to detail and unique craftsmanship, appealing to customers seeking personalized and high-quality products. Continuous production offers efficiency and scalability, meeting higher demand but often at the expense of the artisanal touch characteristic of handmade goods. Choosing between the two depends on balancing quality with quantity to align with brand values and customer expectations.

Table of Comparison

| Aspect | Small-batch Production | Continuous Production |

|---|---|---|

| Definition | Producing limited quantities of handicrafts in specific runs | Ongoing, uninterrupted manufacturing of handicrafts |

| Customization | High customization, unique designs per batch | Low customization, standardized products |

| Production Volume | Low to moderate | High, large scale |

| Flexibility | Flexible, easy to adjust designs | Rigid process, difficult to change |

| Cost Efficiency | Higher unit cost due to small volume | Lower unit cost from economies of scale |

| Quality Control | Closer attention to detail, higher quality | Consistent quality, less individual attention |

| Lead Time | Longer lead time per batch | Shorter lead time due to constant output |

| Ideal Use | Artisanal handicrafts, limited editions | Mass-market handicraft production |

Understanding Small-batch and Continuous Production in Handicrafts

Small-batch production in handicrafts involves creating limited quantities of unique, high-quality items, allowing artisans to maintain meticulous attention to detail and customization. Continuous production emphasizes efficiency and consistency by manufacturing larger volumes of products in a streamlined process, typically suited for simpler designs or standardized goods. Understanding these approaches helps artisans balance creativity with scalability, meeting diverse market demands while preserving craftsmanship.

Key Differences Between Small-batch and Continuous Production

Small-batch production emphasizes handcrafted quality, customization, and flexibility, producing limited quantities tailored to specific customer needs. Continuous production focuses on high-volume manufacturing, maximizing efficiency, and reducing per-unit costs through automation and standardized processes. Key differences include scale, production speed, level of human involvement, and adaptability to design changes.

Advantages of Small-batch Production for Artisans

Small-batch production allows artisans to maintain high-quality standards by ensuring meticulous attention to each piece, fostering uniqueness and craftsmanship. It offers greater flexibility in design adjustments and customization, enabling creators to respond quickly to market trends and customer preferences. This production method reduces inventory risks and supports sustainable practices by minimizing waste and resource use.

Benefits of Continuous Production in Handicraft Businesses

Continuous production in handicraft businesses ensures consistent product quality and increased manufacturing efficiency by streamlining repetitive processes. This approach reduces lead times and lowers cost per unit, enabling artisans to meet higher demand without compromising craftsmanship. Implementing continuous production supports scalability and sustained revenue growth while maintaining the unique, high-quality attributes of handcrafted goods.

Quality Control: Small-batch vs Continuous Production

Small-batch production allows for meticulous quality control due to the limited quantity of items, enabling artisans to inspect and refine each piece thoroughly. Continuous production, while efficient for mass manufacturing, often relies on automated quality checks that may miss subtle defects present in handcrafted goods. Prioritizing small-batch production ensures superior craftsmanship and consistent quality, essential in the handicraft industry.

Cost Implications of Small-batch and Continuous Methods

Small-batch production in handicrafts often involves higher per-unit costs due to limited economies of scale and increased labor intensity. Continuous production reduces unit costs by streamlining processes and maximizing output efficiency, but may sacrifice customization and artisanal quality. Cost implications in small-batch methods include investment in skilled craftsmanship and material variety, whereas continuous production emphasizes automation and standardized inputs to lower expenses.

Adaptability and Customization in Handicraft Production Models

Small-batch production in handicraft allows for high adaptability and extensive customization, enabling artisans to tailor each product to specific customer preferences. Continuous production focuses on efficiency and consistency, often limiting the ability to implement unique design alterations or respond quickly to changing trends. Handicraft businesses prioritizing personalized craftsmanship benefit from small-batch models that support creative flexibility and detailed customization.

Environmental Impact: Sustainable Choices in Production

Small-batch production in handicrafts minimizes environmental impact by reducing waste and conserving resources through more precise material use and less energy consumption. Continuous production often leads to higher resource depletion and increased carbon emissions due to large-scale, nonstop manufacturing processes. Prioritizing small-batch methods supports sustainability by fostering eco-friendly practices and minimizing the ecological footprint within the handmade goods industry.

Meeting Market Demand: Which Production Method Wins?

Small-batch production excels in meeting niche market demands with tailored, high-quality handicraft products, allowing artisans to quickly adapt to consumer preferences and seasonal trends. Continuous production suits mass-market demands by enabling consistent output and economies of scale but often sacrifices customization and craftsmanship. For unique, personalized handicrafts, small-batch production remains the preferred method to satisfy discerning customers seeking authenticity and exclusivity.

Choosing the Right Production Strategy for Your Handicraft Business

Small-batch production in handicraft businesses allows for greater customization, higher-quality control, and reduced inventory risk, making it ideal for artisanal, unique products. Continuous production suits businesses targeting larger markets with consistent demand, enabling cost efficiency and faster turnaround times. Evaluating product complexity, market size, and customer preferences helps determine the optimal strategy for profitability and brand reputation.

Small-batch Production vs Continuous Production Infographic

bizdif.com

bizdif.com