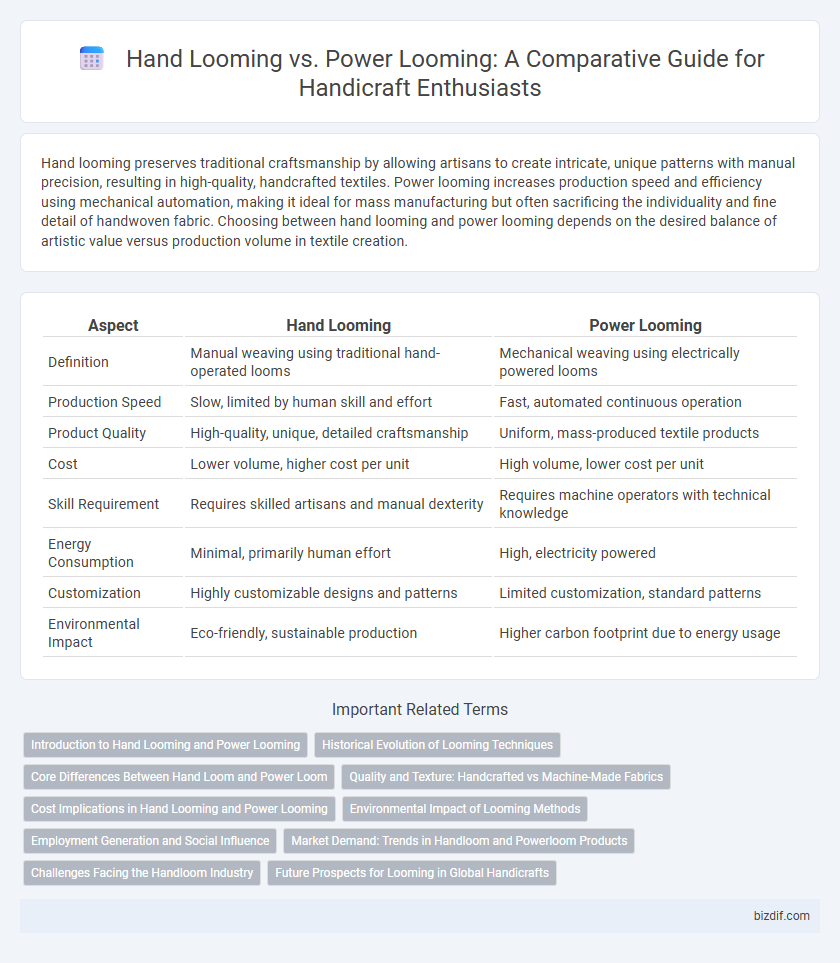

Hand looming preserves traditional craftsmanship by allowing artisans to create intricate, unique patterns with manual precision, resulting in high-quality, handcrafted textiles. Power looming increases production speed and efficiency using mechanical automation, making it ideal for mass manufacturing but often sacrificing the individuality and fine detail of handwoven fabric. Choosing between hand looming and power looming depends on the desired balance of artistic value versus production volume in textile creation.

Table of Comparison

| Aspect | Hand Looming | Power Looming |

|---|---|---|

| Definition | Manual weaving using traditional hand-operated looms | Mechanical weaving using electrically powered looms |

| Production Speed | Slow, limited by human skill and effort | Fast, automated continuous operation |

| Product Quality | High-quality, unique, detailed craftsmanship | Uniform, mass-produced textile products |

| Cost | Lower volume, higher cost per unit | High volume, lower cost per unit |

| Skill Requirement | Requires skilled artisans and manual dexterity | Requires machine operators with technical knowledge |

| Energy Consumption | Minimal, primarily human effort | High, electricity powered |

| Customization | Highly customizable designs and patterns | Limited customization, standard patterns |

| Environmental Impact | Eco-friendly, sustainable production | Higher carbon footprint due to energy usage |

Introduction to Hand Looming and Power Looming

Hand looming involves weaving fabric manually using traditional hand-operated looms, emphasizing craftsmanship and intricate patterns often found in artisanal textiles. Power looming utilizes mechanized looms powered by electricity, enabling mass production and consistent fabric quality with higher speed and efficiency. The choice between hand looming and power looming impacts the texture, cultural value, and economic scale of textile production.

Historical Evolution of Looming Techniques

Hand looming originated thousands of years ago as a manual craft relying on human skill to interlace threads, forming intricate fabric patterns unique to cultural identities. The Industrial Revolution introduced power looms powered by steam and electricity, exponentially increasing textile production speed and consistency while reducing labor intensity. This technological leap transformed weaving from artisanal craftsmanship into large-scale industrial manufacturing, reshaping global textile economies and accessibility.

Core Differences Between Hand Loom and Power Loom

Handloom weaving is characterized by manual operation, using simple tools to create intricate, heritage-rich textiles with unique textures and limited production speed, emphasizing artisanal craftsmanship. Power looms use mechanized, electrically driven systems to produce fabric at high speed and volume, ensuring uniformity and cost-effectiveness suitable for mass manufacturing. The primary differences lie in the mode of operation, production capacity, fabric quality, and cultural value associated with each weaving method.

Quality and Texture: Handcrafted vs Machine-Made Fabrics

Handloom fabrics exhibit unique texture and superior quality due to the meticulous craftsmanship and natural irregularities in each weave, resulting in breathable, durable, and aesthetically rich textiles. Power loom fabrics offer uniformity and speed but often lack the intricate detail and softness found in handloom products, sometimes producing stiffer, less breathable materials. The choice between handloom and power loom reflects a trade-off between artisanal authenticity with enhanced tactile appeal and mass-produced efficiency.

Cost Implications in Hand Looming and Power Looming

Hand looming involves significant labor costs due to manual weaving processes, resulting in lower production volumes but higher-quality artisanal products. Power looming reduces labor expenses by automating weaving, enabling mass production and lower per-unit costs, but often compromises on fabric uniqueness. The initial investment in power looms is substantial, while hand looms require minimal capital, making cost implications a crucial factor in choosing between handcrafted and machine-made textiles.

Environmental Impact of Looming Methods

Hand looming significantly reduces energy consumption and carbon emissions compared to power looming, which relies heavily on electricity and industrial machinery. The manual process of hand looming produces minimal waste and uses sustainable raw materials, promoting eco-friendly textile production. In contrast, power looming contributes to higher levels of pollution and resource depletion due to large-scale synthetic fiber use and chemical processing.

Employment Generation and Social Influence

Hand looming generates significant rural employment by utilizing skilled artisans, preserving traditional craftsmanship and fostering community livelihoods in handloom clusters. Power looming, while enhancing productivity and meeting large-scale textile demands, often leads to mechanization that reduces direct labor opportunities but contributes to industrial growth and urban migration. Social influence of hand looming strengthens cultural identity and supports sustainable practices, whereas power looming impacts societal structures by shifting workforce dynamics and altering economic dependencies.

Market Demand: Trends in Handloom and Powerloom Products

Handloom products are increasingly favored for their unique craftsmanship and eco-friendly qualities, appealing to a growing market seeking sustainable and artisanal goods. Powerloom products dominate the market due to their mass production capabilities, lower costs, and consistency, meeting the high demand for affordable and readily available textiles. Current trends reveal a rising niche market for handloom textiles in fashion and home decor, while powerloom fabrics remain essential for large-scale garment and industrial textile production.

Challenges Facing the Handloom Industry

Handloom industry faces significant challenges including competition from power looms that offer higher production speed and lower costs, leading to reduced demand for handcrafted textiles. Limited market access, inconsistent raw material supply, and lack of modern technology integration constrain the growth and sustainability of handloom artisans. Preservation of traditional skills is threatened by declining youth involvement and inadequate government support programs.

Future Prospects for Looming in Global Handicrafts

Hand looming continues to thrive in global handicrafts due to its cultural authenticity and sustainable production methods, appealing to eco-conscious consumers. Power looming offers scalability and consistency, meeting increasing demand in mass markets but often lacks artisanal value. Future prospects lie in integrating traditional handloom skills with modern technology to enhance efficiency while preserving craftsmanship for competitive advantage in international markets.

Hand Looming vs Power Looming Infographic

bizdif.com

bizdif.com