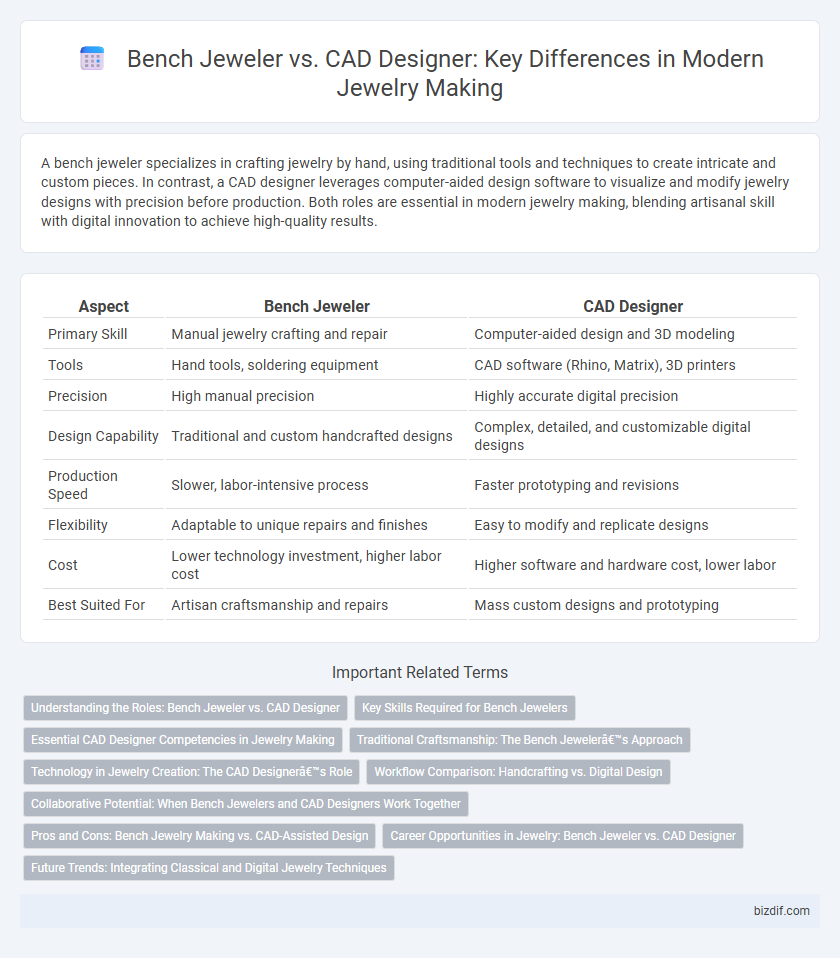

A bench jeweler specializes in crafting jewelry by hand, using traditional tools and techniques to create intricate and custom pieces. In contrast, a CAD designer leverages computer-aided design software to visualize and modify jewelry designs with precision before production. Both roles are essential in modern jewelry making, blending artisanal skill with digital innovation to achieve high-quality results.

Table of Comparison

| Aspect | Bench Jeweler | CAD Designer |

|---|---|---|

| Primary Skill | Manual jewelry crafting and repair | Computer-aided design and 3D modeling |

| Tools | Hand tools, soldering equipment | CAD software (Rhino, Matrix), 3D printers |

| Precision | High manual precision | Highly accurate digital precision |

| Design Capability | Traditional and custom handcrafted designs | Complex, detailed, and customizable digital designs |

| Production Speed | Slower, labor-intensive process | Faster prototyping and revisions |

| Flexibility | Adaptable to unique repairs and finishes | Easy to modify and replicate designs |

| Cost | Lower technology investment, higher labor cost | Higher software and hardware cost, lower labor |

| Best Suited For | Artisan craftsmanship and repairs | Mass custom designs and prototyping |

Understanding the Roles: Bench Jeweler vs. CAD Designer

Bench jewelers specialize in hands-on fabrication, repair, and finishing of jewelry using traditional tools and techniques, ensuring each piece meets high standards of craftsmanship. CAD designers utilize advanced computer-aided design software to create precise, customizable digital models that streamline the production process and enable complex, innovative designs. Understanding these roles highlights the complementary skills essential for modern jewelry making, combining artisanal expertise with technological innovation.

Key Skills Required for Bench Jewelers

Bench jewelers require expert manual dexterity, precision soldering, and stone setting skills to craft and repair intricate jewelry pieces. Proficiency in metalworking techniques, such as shaping, engraving, and polishing, ensures high-quality, detailed finishes. Strong knowledge of gemstones, materials, and traditional tools distinguishes bench jewelers from CAD designers who primarily focus on digital modeling.

Essential CAD Designer Competencies in Jewelry Making

Essential CAD designer competencies in jewelry making include proficiency in 3D modeling software such as Rhino, Matrix, or JewelCAD, enabling precise and detailed digital designs. Strong understanding of gemstone settings, metal properties, and manufacturing processes ensures designs are both aesthetically pleasing and feasible for production. Attention to detail, creativity, and the ability to translate client concepts into accurate virtual prototypes are critical skills distinguishing CAD designers from traditional bench jewelers.

Traditional Craftsmanship: The Bench Jeweler’s Approach

The bench jeweler's approach centers on traditional craftsmanship, utilizing hands-on techniques such as soldering, engraving, and stone setting to create unique, custom pieces. This method emphasizes tactile precision and artistic skill, often resulting in jewelry with distinctive character and nuanced detail. Unlike CAD designers who rely on digital models, bench jewelers bring a personal touch through manual fabrication and time-honored tools.

Technology in Jewelry Creation: The CAD Designer’s Role

CAD designers revolutionize jewelry creation by leveraging advanced software to create precise 3D models that streamline the manufacturing process and reduce errors. Unlike traditional bench jewelers who manually craft each piece, CAD designers utilize computer-aided design technology to visualize complex designs with exceptional accuracy and customization. This integration of technology enhances efficiency, allows for intricate detailing, and facilitates easy modifications before production, significantly impacting modern jewelry craftsmanship.

Workflow Comparison: Handcrafting vs. Digital Design

Bench jewelers rely on traditional handcrafting techniques, using tools such as files, saws, and torches to shape metals and set stones, allowing for tactile precision and artistic expression. CAD designers employ software like Rhino or MatrixGold to create detailed 3D models, streamlining design iterations and enabling complex geometries that are difficult to achieve by hand. The workflow for handcrafting demands physical skill and time-intensive processes, while digital design accelerates prototyping and facilitates seamless integration with 3D printing and CNC machining technologies.

Collaborative Potential: When Bench Jewelers and CAD Designers Work Together

Collaboration between bench jewelers and CAD designers unlocks unparalleled creative potential, blending traditional craftsmanship with advanced digital precision to produce intricate, custom pieces. CAD designers translate artistic visions into accurate 3D models, which bench jewelers skillfully bring to life through manual techniques, ensuring both design fidelity and artisanal quality. This synergy enhances efficiency, reduces errors, and expands the possibilities for innovation in jewelry making.

Pros and Cons: Bench Jewelry Making vs. CAD-Assisted Design

Bench jewelry making offers hands-on craftsmanship with direct material manipulation, enabling intricate, one-of-a-kind custom pieces but requires significant skill and time investment. CAD-assisted design streamlines the creative process with precise digital modeling and faster prototyping, ideal for complex or repetitive designs, yet may lack the unique artisanal touch and demands technical proficiency in software. Choosing between bench jeweler and CAD designer depends on project complexity, desired personalization, and production scale.

Career Opportunities in Jewelry: Bench Jeweler vs. CAD Designer

Career opportunities in jewelry vary significantly between bench jewelers and CAD designers. Bench jewelers excel in hands-on craftsmanship, repair, and custom piece creation, often working in traditional jewelry stores or independent workshops. CAD designers leverage advanced software to create precise, complex designs for manufacturers and brands, opening paths in digital production, prototyping, and high-tech jewelry design studios.

Future Trends: Integrating Classical and Digital Jewelry Techniques

Future trends in jewelry making emphasize the integration of classical bench jeweler craftsmanship with advanced CAD design, creating a hybrid approach that enhances precision and creativity. Bench jewelers bring expert hand-finishing skills essential for unique detailing, while CAD designers utilize digital tools to streamline prototyping and complex geometries. This fusion promotes innovation, enabling designers to leverage technology without sacrificing artisanal quality in customized jewelry pieces.

Bench jeweler vs CAD designer Infographic

bizdif.com

bizdif.com