Hand fabrication in jewelry making offers unparalleled precision and artistic expression, allowing artisans to create unique, customized pieces with intricate details. Machine fabrication emphasizes efficiency and consistency, producing high volumes of jewelry with uniform quality and faster turnaround times. Combining both methods can optimize production by balancing craftsmanship and scalability in the jewelry industry.

Table of Comparison

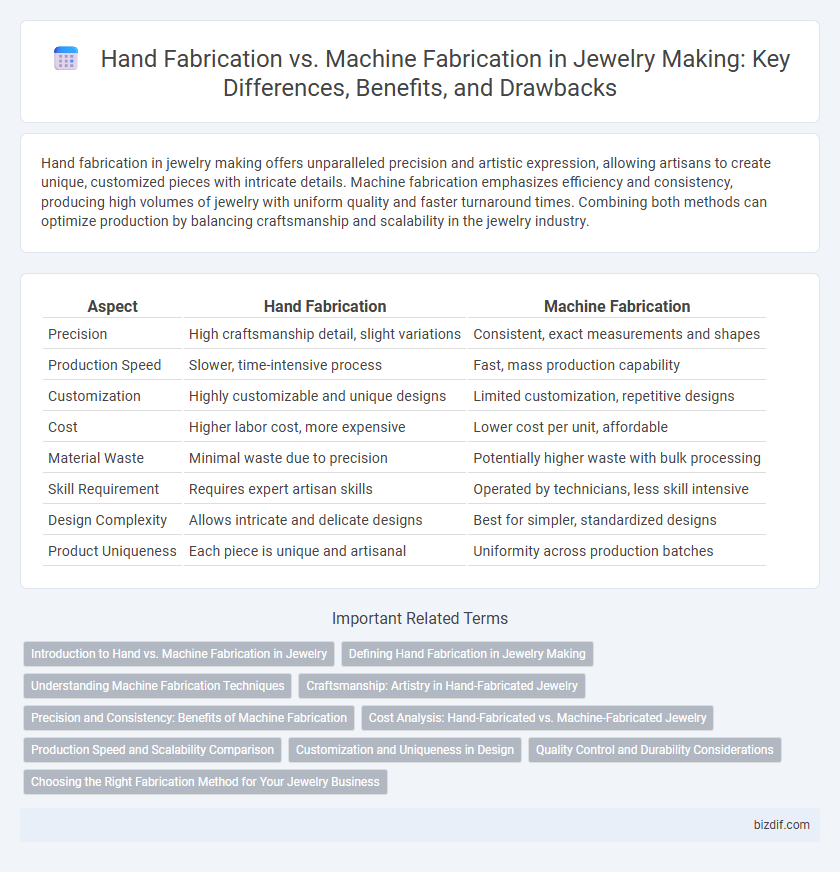

| Aspect | Hand Fabrication | Machine Fabrication |

|---|---|---|

| Precision | High craftsmanship detail, slight variations | Consistent, exact measurements and shapes |

| Production Speed | Slower, time-intensive process | Fast, mass production capability |

| Customization | Highly customizable and unique designs | Limited customization, repetitive designs |

| Cost | Higher labor cost, more expensive | Lower cost per unit, affordable |

| Material Waste | Minimal waste due to precision | Potentially higher waste with bulk processing |

| Skill Requirement | Requires expert artisan skills | Operated by technicians, less skill intensive |

| Design Complexity | Allows intricate and delicate designs | Best for simpler, standardized designs |

| Product Uniqueness | Each piece is unique and artisanal | Uniformity across production batches |

Introduction to Hand vs. Machine Fabrication in Jewelry

Hand fabrication in jewelry making involves skilled artisans shaping and assembling metals using tools like saws, hammers, and torches, allowing for intricate customization and unique designs. Machine fabrication utilizes advanced technologies such as CNC machines, laser cutters, and 3D printers to produce precise, consistent, and scalable components. The choice between hand and machine fabrication impacts craftsmanship quality, production speed, and design complexity in jewelry manufacturing.

Defining Hand Fabrication in Jewelry Making

Hand fabrication in jewelry making involves creating pieces by manually shaping, cutting, and assembling metals and other materials using traditional tools such as saws, files, and torches. This technique allows for intricate designs and custom detailing that reflect the artisan's skill and creativity, distinguishing each piece as unique. Emphasizing craftsmanship, hand fabrication often results in higher-quality, personalized jewelry compared to standard machine-produced items.

Understanding Machine Fabrication Techniques

Machine fabrication techniques in jewelry making employ precision tools such as CNC milling, laser cutting, and 3D printing to create intricate designs with high accuracy and repeatability. These methods enable faster production times compared to hand fabrication, allowing for consistent quality in mass manufacturing. Understanding these technologies is essential for modern jewelers seeking efficiency and scalability without compromising artistic detail.

Craftsmanship: Artistry in Hand-Fabricated Jewelry

Hand fabrication in jewelry making emphasizes meticulous craftsmanship, where artisans precisely shape, solder, and finish each piece by hand, resulting in unique, one-of-a-kind designs with intricate details. This artisanal process allows for greater creative freedom and customization compared to machine fabrication, which often relies on standardized production techniques. The artistry involved in hand-fabricated jewelry ensures exceptional quality, character, and individuality that mechanical methods typically cannot replicate.

Precision and Consistency: Benefits of Machine Fabrication

Machine fabrication in jewelry making ensures unmatched precision and consistency, using computer-aided design (CAD) and CNC machining to produce intricate and uniform pieces. This technology reduces human error, allowing for tight tolerances and repeatable designs that maintain exact detail across multiple items. High precision in machine fabrication supports efficient production workflows and meets industry standards for quality control.

Cost Analysis: Hand-Fabricated vs. Machine-Fabricated Jewelry

Hand-fabricated jewelry typically incurs higher labor costs due to the intensive skilled craftsmanship required, resulting in increased production expenses compared to machine-fabricated pieces. Machine fabrication reduces costs through automation, enabling mass production and consistent precision, thus lowering per-unit pricing. Material wastage is often minimized in machine processes, providing further cost efficiencies that contrast with the more variable material use in hand-fabrication.

Production Speed and Scalability Comparison

Hand fabrication in jewelry making offers superior customization and intricate detail but is limited in production speed and scalability, typically producing a few pieces per day. Machine fabrication significantly increases production speed, enabling mass production of hundreds or thousands of pieces with consistent quality. Scalability favors machine fabrication due to automated processes that reduce labor costs and allow rapid adjustment to market demand.

Customization and Uniqueness in Design

Hand fabrication in jewelry making enables unparalleled customization and unique design details, as each piece is crafted individually by skilled artisans who can adjust every element to client specifications. Machine fabrication offers precision and consistency ideal for mass production but limits the ability to incorporate distinct, personalized features. Custom jewelry clients seeking one-of-a-kind items often prefer hand fabrication for its creative flexibility and artisanal craftsmanship.

Quality Control and Durability Considerations

Hand fabrication in jewelry making allows for meticulous quality control, as artisans can inspect and adjust each piece throughout the process, ensuring precise craftsmanship and unique details. Machine fabrication offers consistent durability by producing uniform components with tightly controlled tolerances, reducing human error and enhancing structural integrity. Both methods emphasize quality and durability, but hand fabrication prioritizes bespoke refinement while machine fabrication excels in repeatability and material strength.

Choosing the Right Fabrication Method for Your Jewelry Business

Hand fabrication offers unparalleled customization and artisanal quality, making it ideal for bespoke or high-end jewelry businesses valuing craftsmanship. Machine fabrication excels in producing large volumes with consistent precision, reducing labor costs and increasing scalability for commercial operations. Evaluating factors like production volume, design complexity, budget, and brand identity helps jewelry businesses select the optimal fabrication method to maximize efficiency and market appeal.

Hand fabrication vs machine fabrication Infographic

bizdif.com

bizdif.com