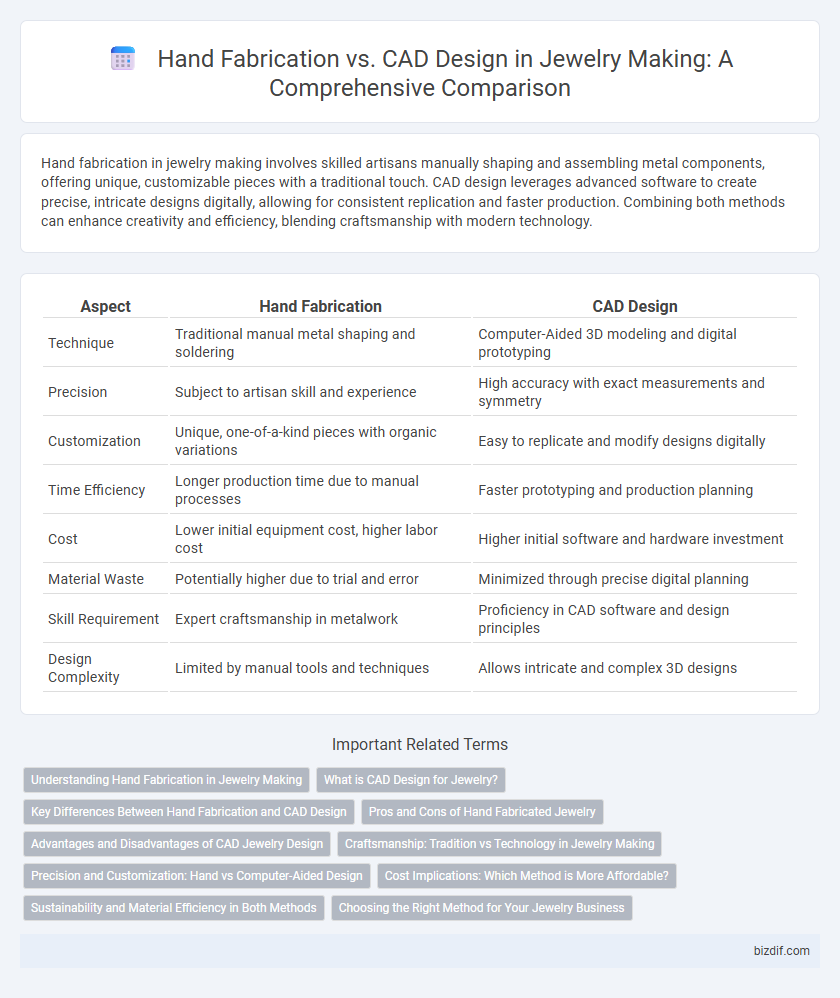

Hand fabrication in jewelry making involves skilled artisans manually shaping and assembling metal components, offering unique, customizable pieces with a traditional touch. CAD design leverages advanced software to create precise, intricate designs digitally, allowing for consistent replication and faster production. Combining both methods can enhance creativity and efficiency, blending craftsmanship with modern technology.

Table of Comparison

| Aspect | Hand Fabrication | CAD Design |

|---|---|---|

| Technique | Traditional manual metal shaping and soldering | Computer-Aided 3D modeling and digital prototyping |

| Precision | Subject to artisan skill and experience | High accuracy with exact measurements and symmetry |

| Customization | Unique, one-of-a-kind pieces with organic variations | Easy to replicate and modify designs digitally |

| Time Efficiency | Longer production time due to manual processes | Faster prototyping and production planning |

| Cost | Lower initial equipment cost, higher labor cost | Higher initial software and hardware investment |

| Material Waste | Potentially higher due to trial and error | Minimized through precise digital planning |

| Skill Requirement | Expert craftsmanship in metalwork | Proficiency in CAD software and design principles |

| Design Complexity | Limited by manual tools and techniques | Allows intricate and complex 3D designs |

Understanding Hand Fabrication in Jewelry Making

Hand fabrication in jewelry making involves crafting pieces by manually shaping metals using tools such as saws, files, and hammers, allowing for intricate, one-of-a-kind designs with high attention to detail. This traditional technique relies heavily on the artisan's skill and experience to manipulate metal sheets, wires, and components, producing unique textures and custom fittings unattainable by automated processes. Understanding hand fabrication is essential for creating personalized jewelry that highlights craftsmanship and artistic expression beyond digital precision.

What is CAD Design for Jewelry?

CAD design for jewelry involves using computer-aided software to create precise 3D models of jewelry pieces. This technology allows designers to visualize intricate details and make modifications easily before production. CAD enhances accuracy, reduces material waste, and enables complex designs that might be difficult to achieve with traditional hand fabrication.

Key Differences Between Hand Fabrication and CAD Design

Hand fabrication in jewelry making involves manually shaping and assembling metals and gemstones using traditional tools, which allows for intricate, customized details and a tactile craftsmanship experience. CAD design utilizes computer software to create precise digital models, enabling efficient modifications, consistent reproducibility, and seamless integration with 3D printing or CNC machining processes. The key differences lie in the level of manual skill, design flexibility, production speed, and the ability to visualize complex geometries before manufacturing.

Pros and Cons of Hand Fabricated Jewelry

Hand fabricated jewelry offers unparalleled craftsmanship, allowing for intricate, personalized designs that reflect the artisan's skill and creativity. This method provides greater control over details and unique finishes, making each piece one-of-a-kind, though it can be more time-consuming and costly compared to CAD design. However, hand fabrication's reliance on traditional techniques may limit complex geometries achievable with CAD software but enhances the authenticity and tactile quality prized by collectors.

Advantages and Disadvantages of CAD Jewelry Design

CAD jewelry design offers precise customization, allowing intricate and complex patterns that are difficult to achieve with hand fabrication, enhancing creativity and reducing production time. It enables easy modifications and rapid prototyping, minimizing material waste and improving efficiency in design iterations. However, CAD requires significant software expertise and upfront investment in technology, and it may lack the unique artisanal touch and character inherent in handcrafted jewelry pieces.

Craftsmanship: Tradition vs Technology in Jewelry Making

Hand fabrication in jewelry making emphasizes traditional craftsmanship, where skilled artisans manually shape, solder, and texture metals to create unique pieces reflecting personal artistry and heritage techniques. CAD design leverages advanced software to produce precise, complex designs with efficiency and repeatability, enabling intricate detailing that might be difficult or time-consuming by hand. Combining both methods often results in innovative jewelry that balances the tactile quality of handcrafted work with the accuracy and customization possibilities of digital technology.

Precision and Customization: Hand vs Computer-Aided Design

Hand fabrication in jewelry making offers unparalleled customization through skilled craftsmanship, allowing intricate details that reflect personal artistry and traditional techniques. Computer-Aided Design (CAD) enhances precision by enabling exact measurements, complex geometries, and consistent replication, which are difficult to achieve manually. Combining hand fabrication with CAD design optimizes both creative flexibility and technical accuracy for bespoke jewelry pieces.

Cost Implications: Which Method is More Affordable?

Hand fabrication in jewelry making typically involves higher labor costs due to the skill and time required for manual work, making it less affordable for large-scale production. CAD design reduces expenses by streamlining the design process and enabling precise, repeatable models, which lowers overall manufacturing costs, especially for intricate designs. For budget-conscious jewelers, CAD design offers a cost-effective solution without compromising customization and detail quality.

Sustainability and Material Efficiency in Both Methods

Hand fabrication in jewelry making often results in minimal material waste due to precise manual cutting and shaping, promoting sustainable craftsmanship. CAD design enhances material efficiency by enabling accurate mapping and simulation, reducing errors and excess use of precious metals. Both methods contribute to sustainable jewelry production by optimizing resource use--hand fabrication through skilled material handling and CAD through digital precision.

Choosing the Right Method for Your Jewelry Business

Hand fabrication offers unparalleled customization and artisanal quality, ideal for bespoke or limited-edition jewelry collections. CAD design enhances precision and scalability, streamlining production for high-volume orders and intricate designs with repeatable accuracy. Evaluating your business goals, target market, and production capacity helps determine whether handcrafted techniques or digital modeling best suits your jewelry manufacturing needs.

Hand Fabrication vs CAD Design Infographic

bizdif.com

bizdif.com