CAD design in jewelry making offers precise, scalable, and easily modifiable models that streamline the creation process and reduce errors. Traditional sketching allows for more artistic freedom and immediate visualization of creative ideas, capturing unique hand-drawn aesthetics. Combining CAD design with traditional sketching can enhance both technical accuracy and artistic expression in custom jewelry pieces.

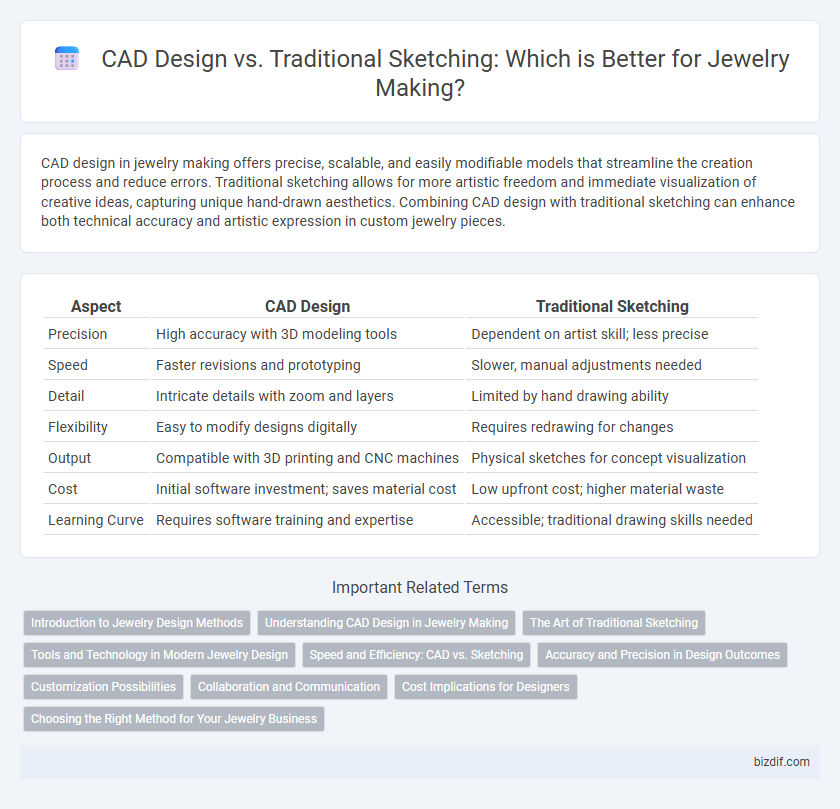

Table of Comparison

| Aspect | CAD Design | Traditional Sketching |

|---|---|---|

| Precision | High accuracy with 3D modeling tools | Dependent on artist skill; less precise |

| Speed | Faster revisions and prototyping | Slower, manual adjustments needed |

| Detail | Intricate details with zoom and layers | Limited by hand drawing ability |

| Flexibility | Easy to modify designs digitally | Requires redrawing for changes |

| Output | Compatible with 3D printing and CNC machines | Physical sketches for concept visualization |

| Cost | Initial software investment; saves material cost | Low upfront cost; higher material waste |

| Learning Curve | Requires software training and expertise | Accessible; traditional drawing skills needed |

Introduction to Jewelry Design Methods

CAD design in jewelry making offers precision and the ability to create complex, highly detailed models with 3D visualization, reducing errors before production. Traditional sketching relies on hand-drawn concepts that capture artistic expression and allow for immediate creative exploration, but may lack the accuracy of digital methods. Both CAD and sketching are essential in the jewelry design process, balancing technical innovation with creative spontaneity.

Understanding CAD Design in Jewelry Making

CAD design in jewelry making revolutionizes the creative process by enabling precise, three-dimensional modeling with advanced software tools such as Rhino, MatrixGold, and JewelCAD. This digital approach allows designers to visualize intricate details, make quick modifications, and produce accurate prototypes with 3D printing, significantly reducing material waste and production time. Integrating CAD design enhances customization capabilities and facilitates seamless communication between designers and manufacturers, improving overall efficiency and craftsmanship quality.

The Art of Traditional Sketching

Traditional sketching in jewelry making captures the artisan's original vision through hand-drawn designs that emphasize individuality and craftsmanship. This method allows for spontaneous creativity, detailed line work, and organic shapes that often inspire unique, personalized pieces. While CAD design offers precision and efficiency, the art of traditional sketching preserves the human touch integral to bespoke jewelry creation.

Tools and Technology in Modern Jewelry Design

CAD design in modern jewelry utilizes advanced software like Rhino and MatrixGold, enabling precise 3D modeling and intricate customization that traditional sketching with pencils and paper cannot achieve. Digital tools offer enhanced efficiency, allowing designers to visualize and modify pieces with high accuracy before production, reducing errors and material waste. Traditional sketching remains valuable for initial concept development but lacks the scalability and technical integration inherent in CAD technology.

Speed and Efficiency: CAD vs. Sketching

CAD design significantly accelerates the jewelry making process by enabling precise modifications and instant visualizations, reducing the time from concept to prototype compared to traditional sketching. Traditional sketching, while valuable for initial creativity, often requires multiple revisions and lacks the immediate accuracy of digital models. The efficiency of CAD is enhanced by tools like 3D rendering and automated measurements, streamlining workflow and minimizing errors in jewelry design.

Accuracy and Precision in Design Outcomes

CAD design in jewelry making enables exceptional accuracy and precision by utilizing digital tools that create detailed 3D models, minimizing human error and allowing exact measurements to the micron level. Traditional sketching, while artistically valuable, often lacks the precise dimensional control needed for intricate designs, resulting in potential variations between concept and final piece. The digital accuracy of CAD not only streamlines production but also enhances consistency in replicating complex jewelry components.

Customization Possibilities

CAD design offers unparalleled customization possibilities in jewelry making by enabling precise modifications and intricate detailing that are difficult to achieve with traditional sketching. Designers can easily experiment with various gemstones, metals, and shapes in real-time, ensuring a perfect fit and unique personalization for each piece. In contrast, traditional sketching relies heavily on the artist's manual skill and interpretation, limiting the complexity and repetition accuracy of custom designs.

Collaboration and Communication

CAD design in jewelry making enables seamless collaboration through digital files that can be easily shared and edited in real time, enhancing communication between designers, clients, and manufacturers. Traditional sketching offers a more tactile and immediate expression of creativity but often requires physical meetings and can lead to slower feedback loops. Integrating CAD tools with hand-drawn sketches bridges the gap by combining precise digital communication with the personal touch of traditional artistry.

Cost Implications for Designers

CAD design significantly reduces material waste and prototyping expenses compared to traditional sketching, lowering overall production costs for jewelry designers. Digital tools enable precise alterations and quick iterations without the need for costly physical models, streamlining the design process. While initial investment in CAD software and hardware can be high, long-term savings and increased efficiency often outweigh these upfront costs.

Choosing the Right Method for Your Jewelry Business

Choosing between CAD design and traditional sketching in jewelry making depends on factors like project complexity, precision requirements, and production scale. CAD design offers enhanced accuracy, 3D visualization, and easier modifications, ideal for intricate or mass-produced pieces. Traditional sketching allows for personal creativity and quicker initial concept development, suited for bespoke or artisanal jewelry businesses emphasizing unique craftsmanship.

CAD Design vs Traditional Sketching Infographic

bizdif.com

bizdif.com