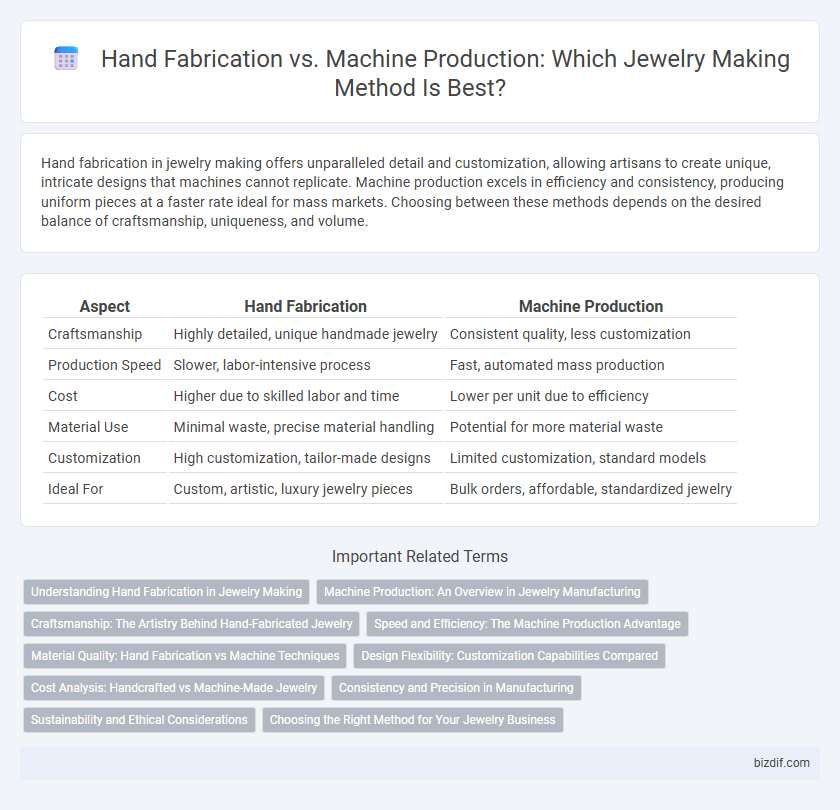

Hand fabrication in jewelry making offers unparalleled detail and customization, allowing artisans to create unique, intricate designs that machines cannot replicate. Machine production excels in efficiency and consistency, producing uniform pieces at a faster rate ideal for mass markets. Choosing between these methods depends on the desired balance of craftsmanship, uniqueness, and volume.

Table of Comparison

| Aspect | Hand Fabrication | Machine Production |

|---|---|---|

| Craftsmanship | Highly detailed, unique handmade jewelry | Consistent quality, less customization |

| Production Speed | Slower, labor-intensive process | Fast, automated mass production |

| Cost | Higher due to skilled labor and time | Lower per unit due to efficiency |

| Material Use | Minimal waste, precise material handling | Potential for more material waste |

| Customization | High customization, tailor-made designs | Limited customization, standard models |

| Ideal For | Custom, artistic, luxury jewelry pieces | Bulk orders, affordable, standardized jewelry |

Understanding Hand Fabrication in Jewelry Making

Hand fabrication in jewelry making involves crafting each component manually using tools such as saws, files, and soldering torches, allowing for precise customization and intricate detailing. This method emphasizes the jeweler's skill and artistry, producing unique pieces with exceptional craftsmanship that machine production often cannot replicate. Hand-fabricated jewelry offers superior control over design modifications and material choices, resulting in high-quality, personalized treasures.

Machine Production: An Overview in Jewelry Manufacturing

Machine production in jewelry manufacturing utilizes advanced technologies such as CNC machining, laser cutting, and 3D printing to achieve high precision and consistency. This method allows for mass production of intricate designs with reduced labor costs and faster turnaround times compared to traditional hand fabrication. Automation enhances the scalability of jewelry production while maintaining tight tolerances and repeatability across large volumes.

Craftsmanship: The Artistry Behind Hand-Fabricated Jewelry

Hand-fabricated jewelry showcases unparalleled craftsmanship through meticulous techniques like soldering, shaping, and engraving, which imbue each piece with unique artistry and character. Unlike machine production, which prioritizes speed and uniformity, hand fabrication emphasizes precision and individualized detail, resulting in jewelry that reflects the artisan's skill and creativity. This dedication to craftsmanship not only enhances the aesthetic value but also preserves traditional methods that machine production cannot replicate.

Speed and Efficiency: The Machine Production Advantage

Machine production in jewelry making significantly outpaces hand fabrication by enabling rapid, consistent output through automated processes such as casting, stamping, and CNC machining. This efficiency reduces labor costs and shortens production cycles, allowing manufacturers to meet high-volume demands effectively. Advanced machinery also enhances precision and repeatability, minimizing material waste and maximizing overall productivity.

Material Quality: Hand Fabrication vs Machine Techniques

Hand fabrication in jewelry making preserves superior material quality by allowing artisans to meticulously select and manipulate metals and gemstones, ensuring minimal stress and damage during shaping. Machine production often involves automated processes that can introduce microfractures or compromised integrity in metals due to high-pressure stamping or casting. Precision and control in hand fabrication lead to enhanced durability and aesthetic value of the final jewelry piece compared to mass-produced machine techniques.

Design Flexibility: Customization Capabilities Compared

Hand fabrication in jewelry making offers superior design flexibility, enabling intricate customization that machines often cannot replicate due to their standardized processes. Artisans can manipulate metals and gemstones with precision tailored to individual client specifications, creating unique, one-of-a-kind pieces. Machine production excels in consistency and speed but typically limits personalization options, making it less ideal for bespoke or highly detailed designs.

Cost Analysis: Handcrafted vs Machine-Made Jewelry

Hand-fabricated jewelry demands higher labor costs due to skilled craftsmanship and time-intensive processes, resulting in premium pricing. Machine-made jewelry benefits from economies of scale and automation, significantly reducing production expenses and retail prices. The cost analysis reveals handcrafted pieces offer unique value and customization, while machine production excels in affordability and mass production efficiency.

Consistency and Precision in Manufacturing

Hand fabrication in jewelry making offers unique craftsmanship but may vary slightly in consistency and precision due to the artisan's manual techniques. Machine production ensures uniformity and high precision by utilizing automated processes that replicate designs with exact measurements and minimal errors. Consistent quality control in machine manufacturing often results in jewelry that meets strict industry standards for accuracy and detail.

Sustainability and Ethical Considerations

Hand fabrication in jewelry making significantly reduces environmental impact by minimizing energy consumption and waste, contrasting with machine production that often relies on high-energy processes and generates substantial material scraps. Ethically, handcrafting supports artisan communities by preserving traditional skills and ensuring fair labor conditions, whereas mass-produced jewelry frequently involves questionable labor practices in lower-cost manufacturing hubs. Choosing hand-fabricated pieces promotes sustainable sourcing and transparent supply chains, aligning with growing consumer demand for responsible and eco-friendly jewelry.

Choosing the Right Method for Your Jewelry Business

Hand fabrication in jewelry making offers unparalleled customization, allowing artisans to create bespoke, intricate designs that meet niche market demands and command higher price points. Machine production excels in consistency and efficiency, enabling large-scale manufacturing with reduced labor costs, ideal for businesses targeting mass-market sales and rapid inventory turnover. Evaluating your brand's target audience, product complexity, and production volume is essential to selecting the optimal method that balances quality, cost, and scalability.

Hand fabrication vs Machine production Infographic

bizdif.com

bizdif.com