Hand fabrication in jewelry making delivers unique, customizable pieces through skilled craftsmanship and intricate detailing that machines cannot replicate. Machine manufacture offers high efficiency and consistent precision, ideal for mass production and uniform designs. Choosing between the two depends on the desired balance of artistry and scalability in jewelry creation.

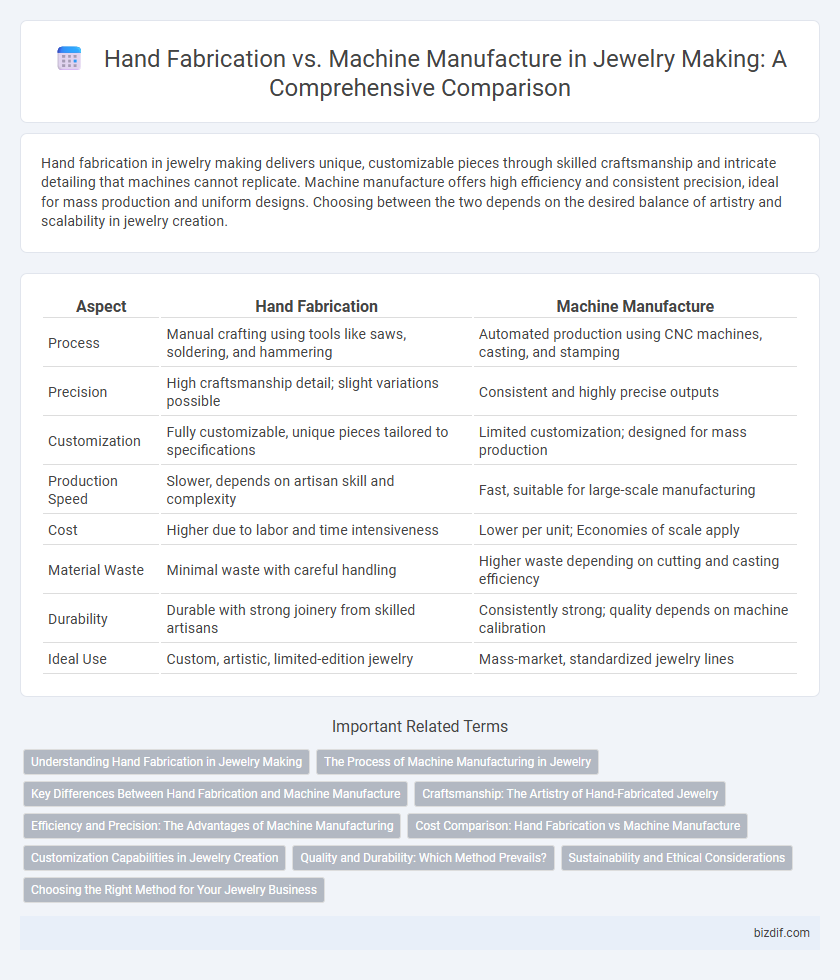

Table of Comparison

| Aspect | Hand Fabrication | Machine Manufacture |

|---|---|---|

| Process | Manual crafting using tools like saws, soldering, and hammering | Automated production using CNC machines, casting, and stamping |

| Precision | High craftsmanship detail; slight variations possible | Consistent and highly precise outputs |

| Customization | Fully customizable, unique pieces tailored to specifications | Limited customization; designed for mass production |

| Production Speed | Slower, depends on artisan skill and complexity | Fast, suitable for large-scale manufacturing |

| Cost | Higher due to labor and time intensiveness | Lower per unit; Economies of scale apply |

| Material Waste | Minimal waste with careful handling | Higher waste depending on cutting and casting efficiency |

| Durability | Durable with strong joinery from skilled artisans | Consistently strong; quality depends on machine calibration |

| Ideal Use | Custom, artistic, limited-edition jewelry | Mass-market, standardized jewelry lines |

Understanding Hand Fabrication in Jewelry Making

Hand fabrication in jewelry making involves skilled artisans shaping and assembling metal components using traditional tools such as hammers, saws, and soldering torches, resulting in unique, customizable pieces. This method allows for intricate detailing and personalization that machines often cannot replicate, enhancing the artistic value and craftsmanship of the jewelry. Unlike machine manufacture which emphasizes mass production and uniformity, hand fabrication prioritizes precision, creativity, and quality in every piece.

The Process of Machine Manufacturing in Jewelry

Machine manufacturing in jewelry involves precision techniques such as casting, stamping, and CNC milling to produce consistent and intricate designs at scale. Advanced machinery enables rapid replication of detailed patterns with minimal human intervention, ensuring uniformity and reducing production time. This process is ideal for mass-market jewelry, balancing efficiency with high-quality finishes.

Key Differences Between Hand Fabrication and Machine Manufacture

Hand fabrication in jewelry making involves skilled artisans shaping and assembling pieces manually, allowing for unique, customizable designs with intricate details. Machine manufacture relies on automated processes such as casting and stamping, producing consistent, high-volume output at faster speeds but with less individual variation. Key differences include the level of craftsmanship, production time, scalability, and cost, where hand fabrication emphasizes artistry and customization, while machine manufacture prioritizes efficiency and uniformity.

Craftsmanship: The Artistry of Hand-Fabricated Jewelry

Hand-fabricated jewelry exemplifies unparalleled craftsmanship, where skilled artisans meticulously shape, solder, and finish each piece, ensuring unique detail and artistic expression. Unlike machine manufacture, which often relies on mass production and uniformity, hand fabrication allows for intricate designs and personalized touches that enhance the jewelry's value and distinctiveness. The artistry inherent in hand fabrication emphasizes creativity, precision, and the timeless tradition of jewelry making.

Efficiency and Precision: The Advantages of Machine Manufacturing

Machine manufacturing in jewelry making offers superior efficiency by significantly reducing production time compared to hand fabrication. Advanced computer-aided design (CAD) and computer numerical control (CNC) machines ensure high precision and consistency, minimizing human error and material waste. This technology allows for complex and intricate designs to be replicated with exact accuracy, enhancing both quality and scalability in jewelry production.

Cost Comparison: Hand Fabrication vs Machine Manufacture

Hand fabrication in jewelry making involves skilled artisans meticulously crafting each piece, resulting in higher labor costs and longer production times. Machine manufacture significantly reduces expenses through automation, enabling mass production and consistent quality at a lower per-unit cost. Cost comparison reveals that hand fabrication suits custom, high-end designs while machine manufacturing benefits large-scale, budget-conscious jewelry production.

Customization Capabilities in Jewelry Creation

Hand fabrication in jewelry making offers unparalleled customization capabilities, allowing artisans to create unique, intricately detailed pieces tailored to individual specifications and personal styles. Machine manufacture enables efficient mass production but often limits design flexibility and intricate customization due to standardized processes and patterns. Custom jewelry creation benefits from hand fabrication's adaptability, making it the preferred method for one-of-a-kind pieces with personalized features.

Quality and Durability: Which Method Prevails?

Hand fabrication in jewelry making ensures superior quality and durability through meticulous craftsmanship and individualized attention to detail, resulting in unique, resilient pieces. Machine manufacture offers consistent precision and faster production but often lacks the bespoke sturdiness achievable by skilled artisans. The enduring value and robustness of hand-fabricated jewelry generally surpass machine-made counterparts, making it the preferred method for high-quality, durable designs.

Sustainability and Ethical Considerations

Hand fabrication in jewelry making often offers greater sustainability by minimizing energy consumption and reducing waste compared to machine manufacture, which typically relies on high-energy processes and mass production. Artisans can source ethically obtained materials and employ techniques that prioritize eco-friendly practices, enhancing the environmental and social responsibility of each piece. In contrast, machine manufacturing may involve complex supply chains with less transparency, increasing the risk of unethical sourcing and environmental harm.

Choosing the Right Method for Your Jewelry Business

Hand fabrication allows for unique, customized jewelry pieces with intricate details, appealing to clients seeking personalized designs and artisanal quality. Machine manufacture offers high efficiency and consistency, ideal for mass production and maintaining uniformity across large batches. Selecting the right method depends on your business goals, target market, and desired balance between craftsmanship and scalability.

Hand fabrication vs Machine manufacture Infographic

bizdif.com

bizdif.com