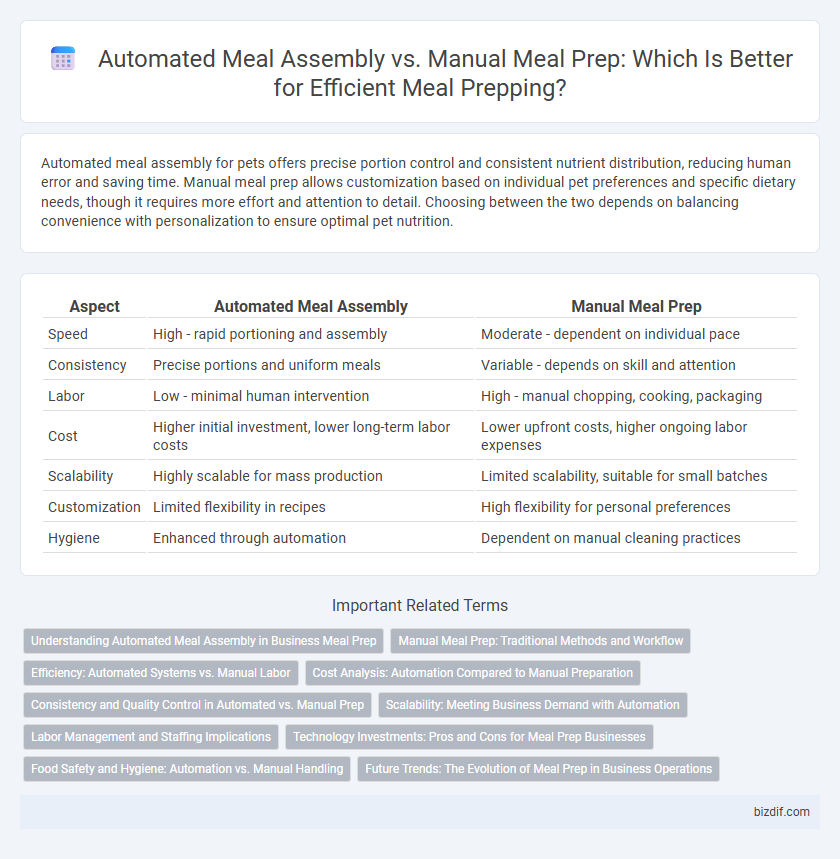

Automated meal assembly for pets offers precise portion control and consistent nutrient distribution, reducing human error and saving time. Manual meal prep allows customization based on individual pet preferences and specific dietary needs, though it requires more effort and attention to detail. Choosing between the two depends on balancing convenience with personalization to ensure optimal pet nutrition.

Table of Comparison

| Aspect | Automated Meal Assembly | Manual Meal Prep |

|---|---|---|

| Speed | High - rapid portioning and assembly | Moderate - dependent on individual pace |

| Consistency | Precise portions and uniform meals | Variable - depends on skill and attention |

| Labor | Low - minimal human intervention | High - manual chopping, cooking, packaging |

| Cost | Higher initial investment, lower long-term labor costs | Lower upfront costs, higher ongoing labor expenses |

| Scalability | Highly scalable for mass production | Limited scalability, suitable for small batches |

| Customization | Limited flexibility in recipes | High flexibility for personal preferences |

| Hygiene | Enhanced through automation | Dependent on manual cleaning practices |

Understanding Automated Meal Assembly in Business Meal Prep

Automated meal assembly uses robotics and conveyor systems to increase efficiency and consistency in business meal prep, reducing human error and labor costs. This technology enables high-volume production with standardized portion control, ensuring food safety and quality compliance. Investing in automated solutions supports scalability and faster turnaround times essential for meeting corporate catering demands.

Manual Meal Prep: Traditional Methods and Workflow

Manual meal prep relies on hands-on techniques such as chopping, portioning, and cooking using traditional kitchen tools like knives, cutting boards, and stovetops. It allows for greater customization of ingredients and portion sizes based on individual dietary needs and preferences. While time-intensive, manual methods foster creativity and control over freshness and quality in meal preparation.

Efficiency: Automated Systems vs. Manual Labor

Automated meal assembly systems significantly enhance efficiency by reducing preparation time through precise, programmable processes and consistent portion control. Manual meal prep relies heavily on human labor, leading to variability in speed and quality while increasing the risk of errors and fatigue. Integration of automated solutions in commercial kitchens can boost productivity by up to 50%, streamlining operations and minimizing labor costs.

Cost Analysis: Automation Compared to Manual Preparation

Automated meal assembly significantly reduces labor costs by minimizing human involvement in repetitive tasks, leading to consistent portion control and reduced food waste. Manual meal prep incurs higher ongoing expenses due to labor intensity, variability in output, and increased potential for errors or spoilage. Initial investment in automated systems is substantial but offers long-term savings and scalability that manual preparation cannot match.

Consistency and Quality Control in Automated vs. Manual Prep

Automated meal assembly ensures uniform portion sizes and precise ingredient distribution, leading to consistent meal quality that meets strict dietary standards. Manual meal prep varies based on individual skill and attention, which can result in inconsistencies in flavor, texture, and nutritional content. Quality control in automated systems relies on standardized processes and real-time monitoring, reducing human error and ensuring compliance with health regulations.

Scalability: Meeting Business Demand with Automation

Automated meal assembly significantly enhances scalability by rapidly increasing production capacity without compromising consistency, making it ideal for meeting high-volume business demand. Unlike manual meal prep, which is limited by human labor constraints and variability, automation ensures precise portioning and uniform quality at scale. This efficiency reduction in labor costs and faster turnaround times supports businesses in expanding their customer base efficiently.

Labor Management and Staffing Implications

Automated meal assembly significantly reduces labor costs by minimizing the need for extensive manual staffing and streamlining repetitive tasks with robotics and conveyor systems. Manual meal prep requires more skilled labor for customization and quality control, increasing staffing demands and scheduling complexities. Efficient labor management in automated systems allows faster scaling with fewer employees, while manual prep remains labor-intensive, impacting workforce allocation and training requirements.

Technology Investments: Pros and Cons for Meal Prep Businesses

Technology investments in automated meal assembly streamline operations by increasing production speed and ensuring consistent portion control, which reduces labor costs and food waste. However, the high initial capital expenditure and maintenance costs can be prohibitive for small to medium meal prep businesses, potentially limiting flexibility in menu customization. Manual meal prep offers greater adaptability and a personalized touch but demands more time and labor, impacting scalability and operational efficiency.

Food Safety and Hygiene: Automation vs. Manual Handling

Automated meal assembly systems significantly reduce contamination risks by minimizing direct human contact, ensuring consistent adherence to food safety protocols through precise temperature controls and sanitation processes. Manual meal prep increases potential exposure to pathogens due to varied hygiene practices and inadvertent cross-contamination during handling. Integration of automation in meal prep optimizes hygiene standards, lowers microbial contamination, and enhances overall food safety compliance.

Future Trends: The Evolution of Meal Prep in Business Operations

Automated meal assembly is transforming the future of meal prep by integrating robotics and AI to enhance efficiency and consistency in business operations. Manual meal prep, while still valued for customization and artisanal quality, faces scalability challenges that automation addresses through streamlined workflows and reduced labor costs. Emerging trends emphasize hybrid models combining automation with human oversight to optimize productivity and maintain food quality.

Automated meal assembly vs Manual meal prep Infographic

bizdif.com

bizdif.com