Automated meal prepping for pets offers consistent portion control and saves time compared to manual methods, reducing the risk of overfeeding or underfeeding. Modern systems often include programmable settings that cater to specific dietary needs and feeding schedules, ensuring pets receive balanced nutrition without daily human intervention. Manual meal prepping, while customizable and cost-effective, demands regular attention and can be prone to measurement inaccuracies and scheduling errors.

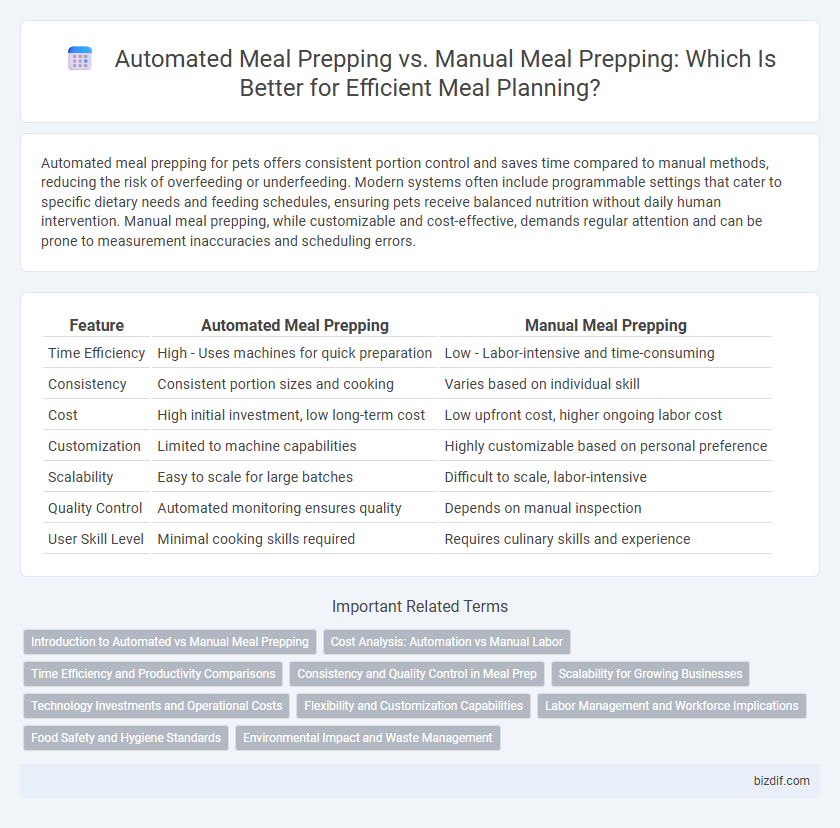

Table of Comparison

| Feature | Automated Meal Prepping | Manual Meal Prepping |

|---|---|---|

| Time Efficiency | High - Uses machines for quick preparation | Low - Labor-intensive and time-consuming |

| Consistency | Consistent portion sizes and cooking | Varies based on individual skill |

| Cost | High initial investment, low long-term cost | Low upfront cost, higher ongoing labor cost |

| Customization | Limited to machine capabilities | Highly customizable based on personal preference |

| Scalability | Easy to scale for large batches | Difficult to scale, labor-intensive |

| Quality Control | Automated monitoring ensures quality | Depends on manual inspection |

| User Skill Level | Minimal cooking skills required | Requires culinary skills and experience |

Introduction to Automated vs Manual Meal Prepping

Automated meal prepping leverages technology and appliances such as smart cookers and meal prep apps to streamline cooking and portioning, reducing time and effort. Manual meal prepping relies on traditional methods involving manual chopping, cooking, and portioning, offering greater flexibility and control over ingredients. Choosing between automated and manual meal prepping depends on personal preferences, available time, and desired convenience level.

Cost Analysis: Automation vs Manual Labor

Automated meal prepping significantly reduces long-term labor costs by minimizing human intervention, leading to increased efficiency and consistent portion control. Manual meal prepping incurs higher labor expenses due to time-intensive processes and variability in preparation speed and accuracy. Initial investment in automated systems may be substantial, but the cost savings from reduced labor and food waste often outweigh these expenses over time.

Time Efficiency and Productivity Comparisons

Automated meal prepping systems reduce preparation time by up to 50%, allowing users to increase weekly productivity with consistent portion control and ingredient organization. Manual meal prepping requires a significant time investment for chopping, cooking, and cleaning, often exceeding two hours for a week's worth of meals, which can reduce overall efficiency. Employing automation in meal preparation enhances time management, enabling individuals to allocate saved time towards other activities or nutritional planning.

Consistency and Quality Control in Meal Prep

Automated meal prepping ensures consistency by precisely measuring ingredients and cooking times, minimizing human error and maintaining uniform portion sizes. Manual meal prepping relies heavily on individual skill and attention, which can lead to variability in taste, texture, and nutritional content across batches. Quality control in automated systems is enhanced through programmable settings and monitoring, while manual processes require stringent personal oversight to achieve comparable standards.

Scalability for Growing Businesses

Automated meal prepping systems enable growing businesses to scale operations efficiently by increasing output while maintaining consistency and quality. Manual meal prepping often limits scalability due to labor-intensive processes and higher risk of human error, which can slow down production as demand rises. Investing in automation technology enhances operational capacity and supports rapid business expansion without compromising product standards.

Technology Investments and Operational Costs

Automated meal prepping leverages advanced robotics and AI technologies, significantly reducing labor expenses and increasing efficiency despite the initial high capital investment in equipment and software. Manual meal prepping incurs lower upfront technology costs but demands greater ongoing operational expenditure due to labor-intensive processes and time consumption. Businesses must balance the upfront technology investments with long-term savings in operational costs to optimize meal prepping strategies for scalability and profitability.

Flexibility and Customization Capabilities

Automated meal prepping offers consistent portion control and time-saving benefits but often lacks the flexibility to adjust recipes on-the-fly, limiting customization for dietary preferences or ingredient swaps. Manual meal prepping provides greater control over ingredient selection, cooking methods, and meal variations, allowing for personalized adjustments based on nutrition goals and taste preferences. Choosing between automated and manual meal prepping hinges on the balance between efficiency and the need for tailored meal customization.

Labor Management and Workforce Implications

Automated meal prepping reduces labor costs by minimizing repetitive manual tasks, enabling a streamlined workforce allocation and enhancing operational efficiency. Manual meal prepping requires skilled labor and flexible scheduling, which can lead to higher labor expenses and increased workforce management complexity. Workforce implications include potential job shifts from manual food preparation to equipment monitoring and maintenance roles in automated settings.

Food Safety and Hygiene Standards

Automated meal prepping systems utilize precise temperature control and sealed environments to minimize contamination risks, ensuring consistent adherence to food safety regulations. Manual meal prepping relies heavily on strict personal hygiene practices and proper sanitation of utensils and surfaces to prevent cross-contamination and foodborne illnesses. Implementing automated solutions can significantly reduce human error, enhancing overall hygiene standards and maintaining food safety throughout the preparation process.

Environmental Impact and Waste Management

Automated meal prepping significantly reduces food waste through precise portion control and optimized ingredient usage, minimizing environmental impact compared to manual meal prepping. Manual meal prepping often leads to excess food spoilage and inefficient use of resources, resulting in higher waste and increased carbon footprint. Using automated systems enhances sustainability by streamlining inventory management and promoting resource-efficient cooking methods.

Automated meal prepping vs manual meal prepping Infographic

bizdif.com

bizdif.com