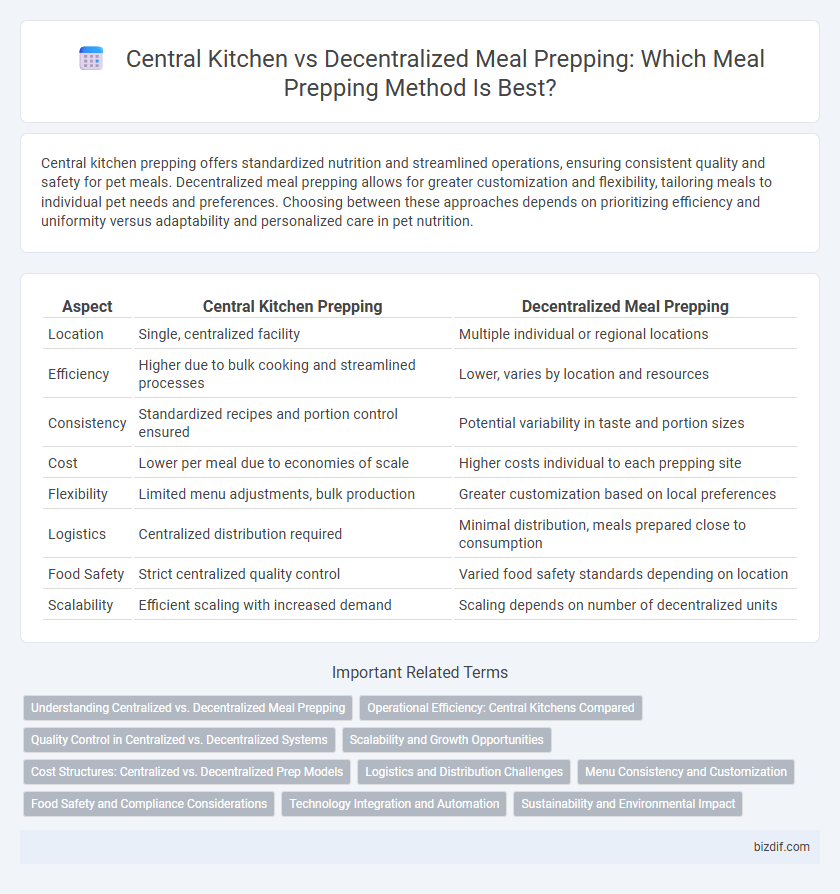

Central kitchen prepping offers standardized nutrition and streamlined operations, ensuring consistent quality and safety for pet meals. Decentralized meal prepping allows for greater customization and flexibility, tailoring meals to individual pet needs and preferences. Choosing between these approaches depends on prioritizing efficiency and uniformity versus adaptability and personalized care in pet nutrition.

Table of Comparison

| Aspect | Central Kitchen Prepping | Decentralized Meal Prepping |

|---|---|---|

| Location | Single, centralized facility | Multiple individual or regional locations |

| Efficiency | Higher due to bulk cooking and streamlined processes | Lower, varies by location and resources |

| Consistency | Standardized recipes and portion control ensured | Potential variability in taste and portion sizes |

| Cost | Lower per meal due to economies of scale | Higher costs individual to each prepping site |

| Flexibility | Limited menu adjustments, bulk production | Greater customization based on local preferences |

| Logistics | Centralized distribution required | Minimal distribution, meals prepared close to consumption |

| Food Safety | Strict centralized quality control | Varied food safety standards depending on location |

| Scalability | Efficient scaling with increased demand | Scaling depends on number of decentralized units |

Understanding Centralized vs. Decentralized Meal Prepping

Centralized meal prepping involves preparing large quantities of meals in a single location, optimizing efficiency, consistency, and ingredient utilization, which suits institutions or large groups. Decentralized meal prepping allows individuals or smaller teams to prepare meals separately, offering flexibility, customization, and freshness but may increase costs and resource duplication. Understanding the trade-offs between centralized and decentralized prepping helps businesses or households balance scale, quality control, and convenience.

Operational Efficiency: Central Kitchens Compared

Central kitchens streamline meal prepping by consolidating tasks, which enhances operational efficiency through bulk purchasing, standardized cooking processes, and reduced labor costs. Decentralized meal prepping, while flexible, often leads to duplicated efforts, increased ingredient waste, and inconsistent food quality across locations. Centralized operations enable better inventory management, faster order processing, and improved scalability for large-scale meal production.

Quality Control in Centralized vs. Decentralized Systems

Central kitchen prepping offers superior quality control through standardized processes, consistent ingredient sourcing, and centralized monitoring, reducing variability in meal preparation. Decentralized meal prepping often faces challenges in maintaining uniform quality due to varied kitchen environments, differing skill levels, and inconsistent adherence to recipes. Centralized systems enable easier implementation of food safety protocols and traceability, enhancing overall meal quality assurance.

Scalability and Growth Opportunities

Central kitchen prepping maximizes scalability by streamlining ingredient sourcing, standardizing recipes, and optimizing labor efficiency, enabling rapid expansion and consistent meal quality across multiple locations. Decentralized meal prepping allows flexibility and customization at local levels but often faces challenges in maintaining uniform standards and managing increased operational costs as scale grows. For growth opportunities, central kitchens provide a more controlled environment to innovate menu offerings and integrate technology for automation, supporting large-scale distribution and brand consistency.

Cost Structures: Centralized vs. Decentralized Prep Models

Central kitchen prepping typically reduces costs through bulk purchasing, streamlined labor, and minimized equipment duplication, leading to economies of scale. Decentralized meal prepping incurs higher expenses due to individual site operations, increased staffing needs, and varied supply chain complexities. Analyzing cost structures reveals centralized models optimize overhead and inventory management, while decentralized setups offer flexibility at potentially greater financial outlays.

Logistics and Distribution Challenges

Central kitchen prepping streamlines bulk meal production and ensures consistent quality but introduces complex logistics challenges, such as transporting meals over long distances while maintaining food safety and temperature control. Decentralized meal prepping reduces reliance on extensive distribution networks, allowing fresher meals delivered locally but requires robust coordination across multiple sites to ensure standardization and inventory management. Efficient route planning and real-time tracking technology are essential to overcoming distribution delays and minimizing food waste in both centralized and decentralized models.

Menu Consistency and Customization

Central kitchen prepping ensures menu consistency by standardizing recipes and portion sizes across multiple locations, reducing variability in taste and presentation. Decentralized meal prepping offers greater customization, allowing individual kitchens to adjust meals based on local preferences and dietary needs. Balancing these approaches can optimize operational efficiency while meeting diverse customer demands.

Food Safety and Compliance Considerations

Central kitchen prepping enhances food safety and compliance by maintaining strict control over hygiene standards, temperature monitoring, and standardized procedures under one regulated environment. Decentralized meal prepping poses challenges in consistent food safety practices due to variation in facility conditions, staff training, and local regulatory compliance. Implementing robust HACCP protocols and real-time quality checks is essential for both methods to minimize contamination risks and ensure regulatory adherence.

Technology Integration and Automation

Central kitchen prepping leverages advanced technology integration and automation systems such as automated cooking equipment, robotic food assembly, and centralized inventory management software to streamline meal production and ensure consistency. Decentralized meal prepping relies more on portable technology solutions and app-based coordination tools that enable real-time communication and customization at multiple locations but may lack the scale of automation found in central kitchens. Efficient use of IoT devices and AI-driven analytics in central kitchens optimizes workflow and reduces labor costs, while decentralized setups focus on flexible technology to accommodate diverse dietary preferences and local sourcing.

Sustainability and Environmental Impact

Central kitchen prepping reduces food waste and energy consumption by optimizing bulk ingredient use and minimizing transportation emissions compared to decentralized meal prepping. Centralized operations enable more efficient resource management, lowering water usage and packaging waste through standardized processes. In contrast, decentralized meal prepping often results in higher carbon footprints due to duplicated efforts, increased food spoilage, and varied packaging practices.

Central kitchen prepping vs decentralized meal prepping Infographic

bizdif.com

bizdif.com