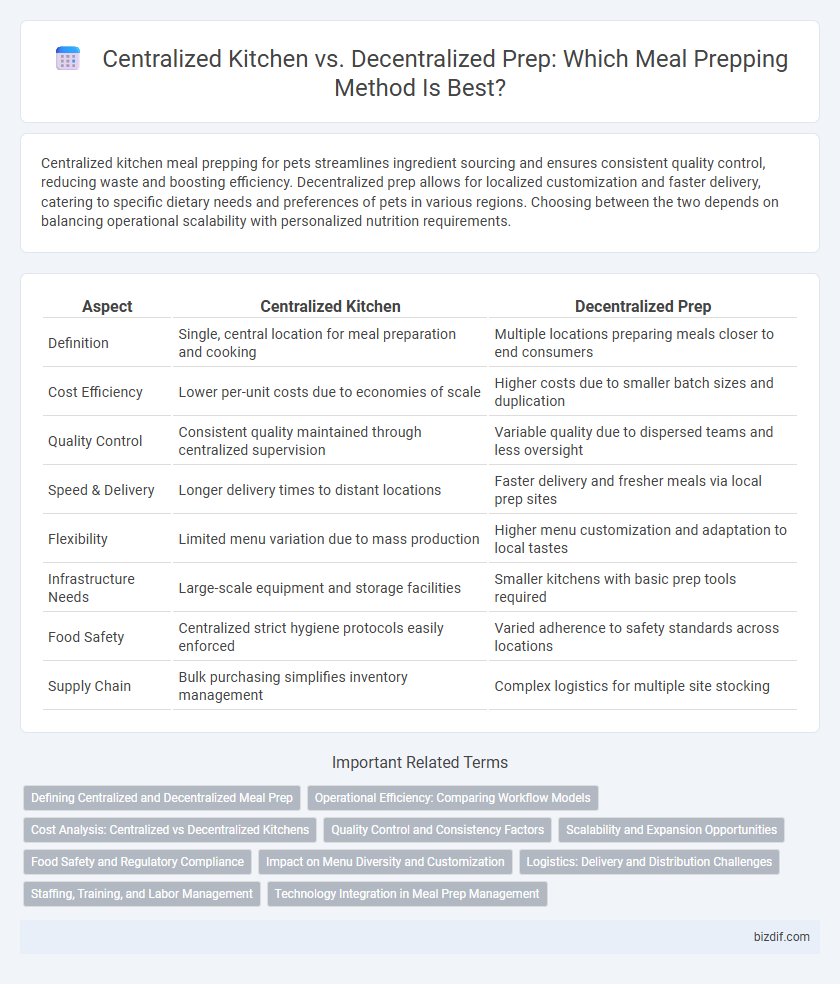

Centralized kitchen meal prepping for pets streamlines ingredient sourcing and ensures consistent quality control, reducing waste and boosting efficiency. Decentralized prep allows for localized customization and faster delivery, catering to specific dietary needs and preferences of pets in various regions. Choosing between the two depends on balancing operational scalability with personalized nutrition requirements.

Table of Comparison

| Aspect | Centralized Kitchen | Decentralized Prep |

|---|---|---|

| Definition | Single, central location for meal preparation and cooking | Multiple locations preparing meals closer to end consumers |

| Cost Efficiency | Lower per-unit costs due to economies of scale | Higher costs due to smaller batch sizes and duplication |

| Quality Control | Consistent quality maintained through centralized supervision | Variable quality due to dispersed teams and less oversight |

| Speed & Delivery | Longer delivery times to distant locations | Faster delivery and fresher meals via local prep sites |

| Flexibility | Limited menu variation due to mass production | Higher menu customization and adaptation to local tastes |

| Infrastructure Needs | Large-scale equipment and storage facilities | Smaller kitchens with basic prep tools required |

| Food Safety | Centralized strict hygiene protocols easily enforced | Varied adherence to safety standards across locations |

| Supply Chain | Bulk purchasing simplifies inventory management | Complex logistics for multiple site stocking |

Defining Centralized and Decentralized Meal Prep

Centralized meal prepping involves preparing large quantities of meals in one location before distributing them to multiple outlets or individuals, optimizing consistency and reducing overall costs. Decentralized meal prep consists of cooking meals at various locations closer to the end consumer, offering greater customization and freshness but potentially increasing logistical complexity. Understanding these definitions is crucial for businesses and consumers aiming to balance efficiency, quality, and operational flexibility in meal preparation.

Operational Efficiency: Comparing Workflow Models

Centralized kitchens streamline meal prepping by consolidating production processes, reducing ingredient waste, and enhancing quality control through standardized workflows. Decentralized prep allows for faster customization and adaptability at individual locations, improving responsiveness but potentially increasing labor and supply chain complexities. Operational efficiency hinges on balancing centralized resource allocation benefits with decentralized agility to meet demand variability in meal prepping systems.

Cost Analysis: Centralized vs Decentralized Kitchens

Centralized kitchens benefit from economies of scale, reducing per-unit costs by consolidating labor, equipment, and ingredient purchasing, leading to significant cost savings in meal prepping operations. Decentralized prep kitchens, while offering flexibility and faster local distribution, often face higher operational expenses due to duplicated resources and inefficiencies in ingredient procurement. Analyzing fixed and variable costs reveals centralized kitchens optimize capital investment, whereas decentralized models increase labor and logistics costs, impacting overall meal prep pricing strategies.

Quality Control and Consistency Factors

Centralized kitchens enable stringent quality control through standardized processes and centralized supervision, ensuring uniform meal preparation and consistent flavor profiles across large batches. Decentralized prep offers flexibility but may introduce variability in ingredient handling and cooking methods, potentially impacting overall quality and consistency. Implementing robust training protocols and real-time monitoring systems helps mitigate inconsistencies in decentralized setups.

Scalability and Expansion Opportunities

Centralized kitchens enable scalable meal prepping by consolidating cooking and packaging processes, reducing overhead costs while maintaining consistent quality across large volumes. Decentralized prep offers flexibility and faster delivery times in local markets but may face challenges in standardizing recipes and managing inventory efficiently as operations expand. Businesses prioritizing rapid scalability and uniformity often favor centralized kitchens, whereas decentralized models appeal to those targeting localized customization and faster market penetration.

Food Safety and Regulatory Compliance

Centralized kitchens streamline food safety protocols by maintaining strict control over hygiene standards, temperature monitoring, and cross-contamination prevention, reducing risks associated with multiple preparation points. Decentralized prep increases complexity in regulatory compliance as varying locations must individually adhere to local health codes, food handling practices, and sanitation requirements. Implementing standardized documentation and regular audits in decentralized setups is essential to ensure consistent food safety and meet regulatory expectations across all sites.

Impact on Menu Diversity and Customization

Centralized kitchens streamline meal prepping by producing large batches of standardized dishes, which can limit menu diversity and reduce customization options for individual preferences or dietary needs. Decentralized prep allows for more localized and flexible cooking processes, supporting a wider variety of menu items tailored to specific customer tastes and nutritional requirements. Businesses prioritizing diverse menus and personalized meals often benefit from decentralized setups, while those focusing on efficiency and consistency lean towards centralized kitchens.

Logistics: Delivery and Distribution Challenges

Centralized kitchens streamline meal prep by concentrating cooking processes in one location but face complex logistics in delivery routes and timing to maintain food quality. Decentralized prep reduces delivery distances and times, minimizing spoilage risk but requires efficient coordination across multiple locations to ensure consistency and inventory management. Balancing delivery frequency and distribution networks is critical to overcoming logistical challenges in both setups.

Staffing, Training, and Labor Management

Centralized kitchens streamline staffing by consolidating meal preparation, requiring specialized training for consistent quality and efficiency, which reduces overall labor costs and simplifies workforce management. Decentralized prep demands more diverse staffing across multiple locations, increasing the complexity of training programs to ensure standardized meal quality and complicating labor scheduling and supervisory roles. Efficient labor management in centralized setups benefits from centralized oversight, while decentralized models necessitate robust communication systems and regional management to maintain productivity and compliance.

Technology Integration in Meal Prep Management

Centralized kitchen models leverage advanced kitchen display systems (KDS) and inventory management software to streamline meal prep workflows and ensure consistency across large volumes. Decentralized prep benefits from cloud-based collaboration platforms and IoT-enabled smart appliances, allowing remote kitchens to synchronize orders and monitor real-time progress. Integration of AI-driven analytics in both models enhances forecasting accuracy, reducing food waste and optimizing resource allocation.

Centralized Kitchen vs Decentralized Prep Infographic

bizdif.com

bizdif.com