Careful ingredient sourcing ensures the highest quality and nutritional value for meal prepping pet food, directly impacting pet health and energy levels. Prioritizing fresh, organic, and species-appropriate ingredients allows for tailored diets that meet specific dietary needs. Efficient meal assembly then transforms these premium ingredients into convenient, balanced portions that simplify feeding routines without compromising freshness or nutrient integrity.

Table of Comparison

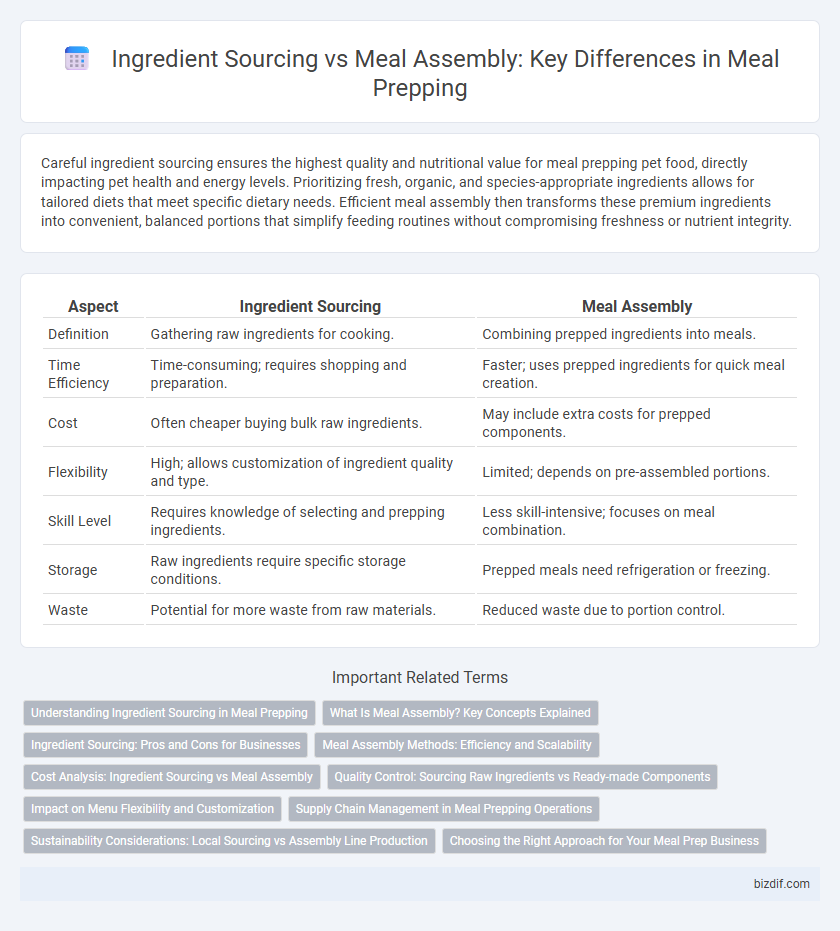

| Aspect | Ingredient Sourcing | Meal Assembly |

|---|---|---|

| Definition | Gathering raw ingredients for cooking. | Combining prepped ingredients into meals. |

| Time Efficiency | Time-consuming; requires shopping and preparation. | Faster; uses prepped ingredients for quick meal creation. |

| Cost | Often cheaper buying bulk raw ingredients. | May include extra costs for prepped components. |

| Flexibility | High; allows customization of ingredient quality and type. | Limited; depends on pre-assembled portions. |

| Skill Level | Requires knowledge of selecting and prepping ingredients. | Less skill-intensive; focuses on meal combination. |

| Storage | Raw ingredients require specific storage conditions. | Prepped meals need refrigeration or freezing. |

| Waste | Potential for more waste from raw materials. | Reduced waste due to portion control. |

Understanding Ingredient Sourcing in Meal Prepping

Understanding ingredient sourcing in meal prepping involves selecting fresh, high-quality produce, proteins, and grains from reliable suppliers to ensure nutritional value and flavor. Prioritizing seasonal and local ingredients reduces costs and enhances sustainability while supporting local economies. Proper ingredient sourcing directly impacts the efficiency of meal assembly by minimizing preparation time and maximizing consistency in portion sizes and meal quality.

What Is Meal Assembly? Key Concepts Explained

Meal assembly involves organizing and combining pre-portioned ingredients into ready-to-cook or ready-to-eat meals, streamlining the cooking process and saving time. Unlike ingredient sourcing, which focuses on selecting quality, fresh, and often seasonal components, meal assembly emphasizes efficiency, portion control, and balanced nutrition in the preparation phase. This method supports consistent meal planning by reducing daily cooking effort and minimizing food waste through precise ingredient utilization.

Ingredient Sourcing: Pros and Cons for Businesses

Ingredient sourcing in meal prepping allows businesses to control quality, cost, and consistency by selecting suppliers that meet specific standards and budgets. However, it poses challenges such as supply chain disruptions, fluctuating prices, and the need for rigorous quality assurance processes. Balancing reliable ingredient sourcing with scalability is crucial for maintaining operational efficiency and customer satisfaction.

Meal Assembly Methods: Efficiency and Scalability

Meal assembly methods for meal prepping prioritize efficiency and scalability by utilizing batch cooking, portion control, and streamlined packaging techniques to reduce preparation time and maintain nutritional consistency. Incorporating automation tools and modular workspace designs further enhances operational flow, enabling large-scale meal preparation while minimizing labor costs. Optimized assembly lines facilitate rapid ingredient combination and customization, supporting diverse dietary needs and improved inventory management.

Cost Analysis: Ingredient Sourcing vs Meal Assembly

Ingredient sourcing often incurs lower upfront costs by purchasing bulk raw materials directly from wholesalers or farmers, reducing per-unit expenses significantly. Meal assembly tends to increase overall costs due to labor, packaging, and storage expenses, which can outweigh savings gained from sourcing cheaper ingredients. Efficient cost analysis reveals that balancing low-cost ingredient procurement with streamlined assembly processes optimizes meal prepping budgets.

Quality Control: Sourcing Raw Ingredients vs Ready-made Components

Quality control in meal prepping hinges on sourcing raw ingredients versus ready-made components, with raw ingredients offering greater transparency and freshness verification. Sourcing raw produce, meats, and spices allows for precise quality checks on texture, aroma, and origin, ensuring superior nutritional value and flavor profiles. Ready-made components expedite assembly but carry risks of hidden additives and inconsistent quality, emphasizing the need for rigorous supplier audits and ingredient certifications.

Impact on Menu Flexibility and Customization

Ingredient sourcing directly influences menu flexibility by determining the variety and quality of available components, enabling diverse recipes and dietary accommodations. Efficient meal assembly leverages these sourced ingredients to customize portions, flavors, and presentations, enhancing personalization for different customer preferences. Strategic coordination between sourcing and assembly maximizes adaptability in menu offerings and optimizes customer satisfaction.

Supply Chain Management in Meal Prepping Operations

Effective supply chain management in meal prepping operations hinges on strategic ingredient sourcing to ensure freshness, cost-efficiency, and sustainability. Optimizing procurement channels and supplier relationships directly impacts inventory accuracy and reduces waste during meal assembly. Coordinated logistics and real-time tracking enhance the seamless transition from ingredient acquisition to efficient portioning and packaging.

Sustainability Considerations: Local Sourcing vs Assembly Line Production

Prioritizing local ingredient sourcing reduces carbon emissions by minimizing transportation distances and supports regional farmers, enhancing overall meal prep sustainability. Assembly line production, while efficient, often relies on ingredients transported over long distances, increasing the environmental footprint and diminishing freshness. Sustainable meal prepping balances eco-friendly local sourcing with streamlined assembly processes to reduce waste and energy consumption.

Choosing the Right Approach for Your Meal Prep Business

Selecting between ingredient sourcing and meal assembly hinges on your business model, target market, and operational capacity. Ingredient sourcing emphasizes quality and variety, allowing for customization and fresh produce, while meal assembly focuses on efficiency and scalability by pre-preparing meals from sourced ingredients. Prioritize supplier reliability, cost-effectiveness, and customer preferences to optimize workflow and profitability in your meal prep business.

Ingredient sourcing vs meal assembly Infographic

bizdif.com

bizdif.com