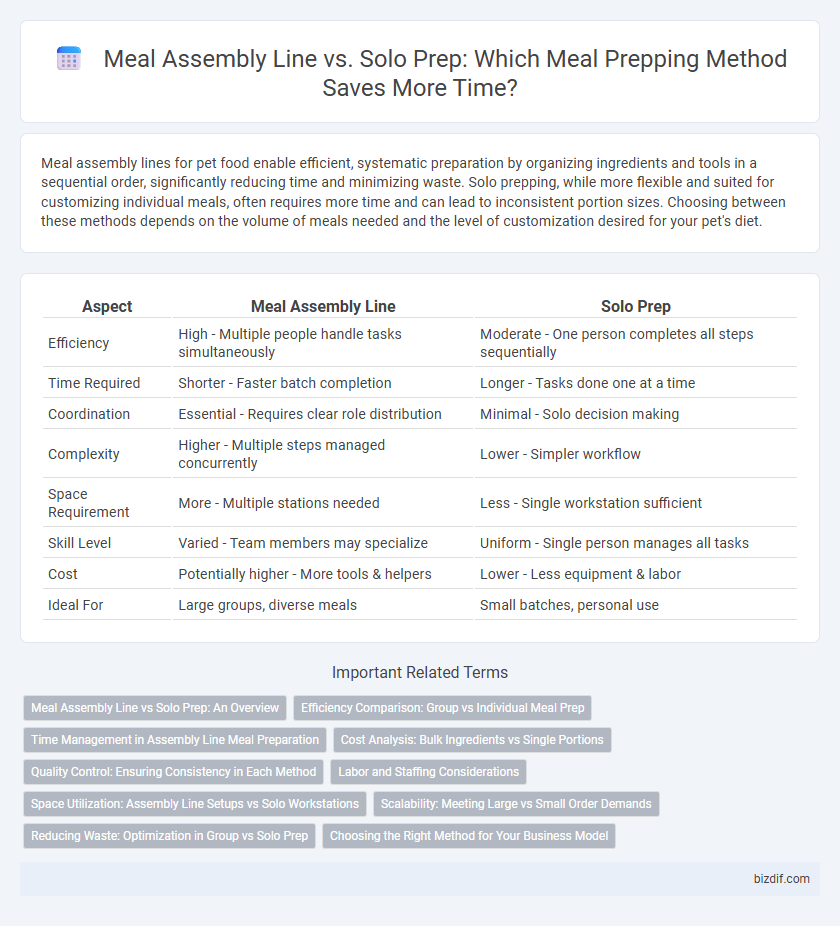

Meal assembly lines for pet food enable efficient, systematic preparation by organizing ingredients and tools in a sequential order, significantly reducing time and minimizing waste. Solo prepping, while more flexible and suited for customizing individual meals, often requires more time and can lead to inconsistent portion sizes. Choosing between these methods depends on the volume of meals needed and the level of customization desired for your pet's diet.

Table of Comparison

| Aspect | Meal Assembly Line | Solo Prep |

|---|---|---|

| Efficiency | High - Multiple people handle tasks simultaneously | Moderate - One person completes all steps sequentially |

| Time Required | Shorter - Faster batch completion | Longer - Tasks done one at a time |

| Coordination | Essential - Requires clear role distribution | Minimal - Solo decision making |

| Complexity | Higher - Multiple steps managed concurrently | Lower - Simpler workflow |

| Space Requirement | More - Multiple stations needed | Less - Single workstation sufficient |

| Skill Level | Varied - Team members may specialize | Uniform - Single person manages all tasks |

| Cost | Potentially higher - More tools & helpers | Lower - Less equipment & labor |

| Ideal For | Large groups, diverse meals | Small batches, personal use |

Meal Assembly Line vs Solo Prep: An Overview

Meal assembly line streamlines meal prepping by dividing tasks among multiple participants, enhancing efficiency and reducing overall preparation time. Solo prep offers flexibility and individual pace but may require longer sessions and stronger organizational skills to maintain consistency. Comparing these methods highlights that meal assembly lines excel in group settings for bulk cooking, while solo prep suits personalized meal customization.

Efficiency Comparison: Group vs Individual Meal Prep

Group meal prep utilizing a meal assembly line significantly increases efficiency by dividing tasks and reducing repetitive actions, enabling faster completion compared to solo prep. Individual meal prepping often takes longer due to multitasking and limited assistance, but it allows for personalized portion control and customization. The collective effort in group prep maximizes time savings, making it ideal for preparing large quantities or complex meals efficiently.

Time Management in Assembly Line Meal Preparation

Meal assembly line prep significantly enhances time management by streamlining repetitive tasks and minimizing downtime between meal components. Organizing ingredients and tools in a systematic flow allows multiple meals to be prepared simultaneously, reducing overall cooking duration. This efficiency makes assembly lines ideal for bulk meal prepping, optimizing productivity compared to solo prep where tasks are handled sequentially.

Cost Analysis: Bulk Ingredients vs Single Portions

Meal assembly lines optimize cost efficiency by utilizing bulk ingredients, significantly reducing per-serving expenses compared to solo prep methods that rely on single portions. Bulk purchasing lowers ingredient costs and minimizes packaging waste, enhancing overall meal prep affordability. Solo prep often incurs higher overhead due to smaller ingredient quantities and increased labor time, impacting the cost-effectiveness of individual meal preparation.

Quality Control: Ensuring Consistency in Each Method

Meal assembly line offers superior quality control by allowing each ingredient to be measured and inspected at every station, ensuring consistent portion sizes and freshness across all meals. Solo prep, while flexible, risks variability in seasoning, cooking times, and ingredient distribution, potentially affecting the uniformity of taste and presentation. Implementing standardized recipes and tools enhances consistency in solo prep but often cannot match the precision and efficiency of an organized assembly line system.

Labor and Staffing Considerations

Meal assembly lines streamline labor by enabling multiple workers to focus on specific tasks, increasing efficiency and reducing prep time compared to solo meal prepping. Solo prep requires fewer staff but significantly more individual time investment, limiting scalability in commercial kitchens. Efficient staffing strategies in meal assembly lines optimize labor costs while maintaining consistent quality through specialized task division.

Space Utilization: Assembly Line Setups vs Solo Workstations

Meal assembly line setups maximize space utilization by organizing ingredients and tools in a sequential flow, reducing movement and increasing efficiency. Solo workstations require more individual space per prep area, often leading to underutilized kitchen zones and scattered supplies. Optimizing space with assembly lines supports higher volume cooking while minimizing clutter and transit time.

Scalability: Meeting Large vs Small Order Demands

Meal assembly lines streamline large-scale meal prepping by enabling efficient, repeatable tasks that boost output and consistency for bulk orders. Solo prep suits smaller demands, offering flexibility and customization but limited scalability due to time and labor constraints. Choosing between the two depends on order volume, with assembly lines excelling in high-demand scenarios and solo prep ideal for personalized, low-volume needs.

Reducing Waste: Optimization in Group vs Solo Prep

Meal assembly lines significantly reduce food waste by streamlining ingredient use and minimizing excess portions through coordinated group efforts. Solo prep often results in inconsistent measurements and leftover ingredients due to less precise planning. Collaborative meal prepping enables better resource allocation and waste reduction by pooling ingredients and sharing responsibilities.

Choosing the Right Method for Your Business Model

Choosing between a meal assembly line and solo prep method depends on your business model's scale and efficiency needs. Assembly lines optimize speed and consistency, ideal for high-volume operations requiring uniform portions and quick turnaround. Solo prep suits smaller, artisan-focused businesses emphasizing customization and quality control in each meal.

Meal Assembly Line vs Solo Prep Infographic

bizdif.com

bizdif.com