Batch pricing in soap making pet products offers cost efficiency by producing multiple bars at once, lowering the overall expense per unit and ensuring consistent quality across the batch. Per bar pricing, however, provides flexibility for small-scale or custom orders, allowing customers to purchase individual bars at a potentially higher price reflecting the tailored craftsmanship. Choosing between batch and per bar pricing depends on production scale, customer demand, and pricing strategy to maximize profitability in the pet soap market.

Table of Comparison

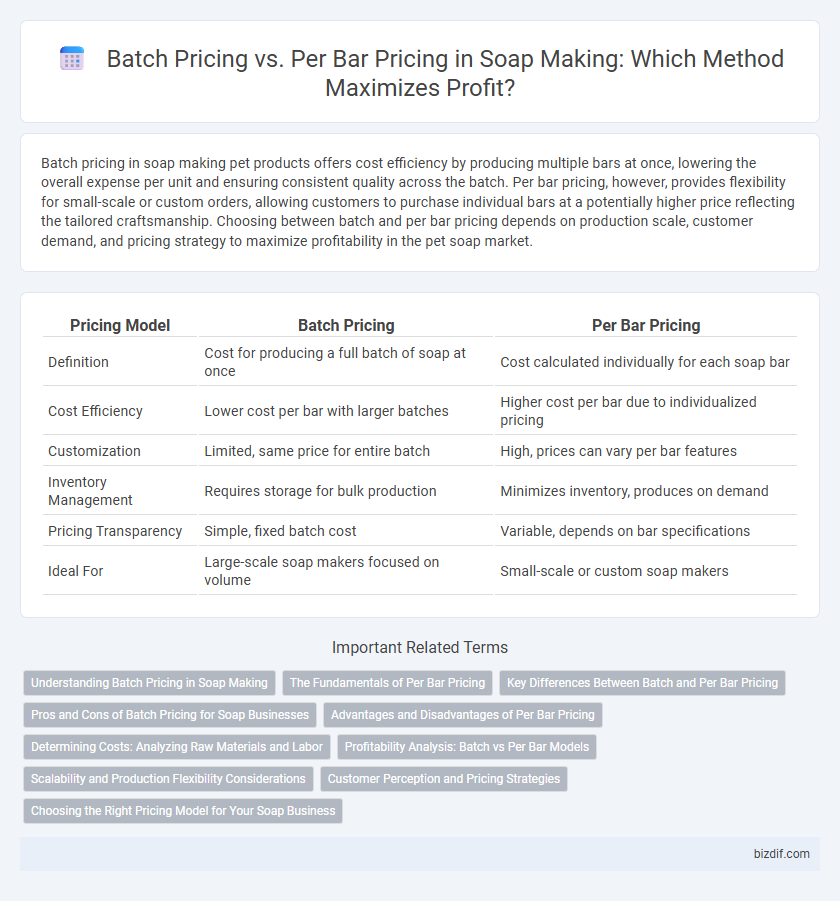

| Pricing Model | Batch Pricing | Per Bar Pricing |

|---|---|---|

| Definition | Cost for producing a full batch of soap at once | Cost calculated individually for each soap bar |

| Cost Efficiency | Lower cost per bar with larger batches | Higher cost per bar due to individualized pricing |

| Customization | Limited, same price for entire batch | High, prices can vary per bar features |

| Inventory Management | Requires storage for bulk production | Minimizes inventory, produces on demand |

| Pricing Transparency | Simple, fixed batch cost | Variable, depends on bar specifications |

| Ideal For | Large-scale soap makers focused on volume | Small-scale or custom soap makers |

Understanding Batch Pricing in Soap Making

Batch pricing in soap making involves calculating the total cost of producing a set quantity of soap bars, which includes raw materials, labor, and overhead expenses. This method provides a comprehensive view of production expenses, enabling more accurate profitability analysis and price setting for the entire batch. Understanding batch pricing helps soap makers optimize ingredient usage, reduce waste, and ensure consistent quality across all bars.

The Fundamentals of Per Bar Pricing

Per bar pricing in soap making directly reflects the individual cost of ingredients, labor, and packaging, allowing for precise profit margin calculation on each soap unit sold. This method simplifies inventory management and helps small-scale producers adjust prices based on fluctuations in material costs or market demand. Understanding per bar pricing fundamentals ensures transparent pricing strategies that improve customer trust and business sustainability.

Key Differences Between Batch and Per Bar Pricing

Batch pricing involves calculating the total cost for producing an entire batch of soap, accounting for ingredients, labor, and overhead as a single unit, which can lower costs per bar when producing in large quantities. Per bar pricing breaks down the expenses to determine the cost of each individual soap bar, allowing for more precise pricing and profitability analysis on a smaller scale. Key differences include economies of scale impact, cost allocation accuracy, and pricing flexibility, with batch pricing favoring volume production and per bar pricing enabling detailed market adjustments.

Pros and Cons of Batch Pricing for Soap Businesses

Batch pricing in soap making allows businesses to calculate costs based on the entire quantity produced, promoting streamlined inventory management and potentially lowering production expenses per unit. This method can simplify bookkeeping and forecasting but may obscure individual bar profitability and limit pricing flexibility for varied product lines. Not offering detailed per-bar cost analysis can challenge precise profit margin control and pricing strategies tailored to different soap varieties.

Advantages and Disadvantages of Per Bar Pricing

Per bar pricing in soap making ensures clear transparency for customers, allowing for precise cost assessment of individual units, which can enhance buying confidence and facilitate easier inventory management. However, this approach may complicate pricing consistency when bars vary in size or quality, potentially leading to customer dissatisfaction or perceived unfairness. Moreover, per bar pricing can increase administrative workload due to the need for detailed tracking and differentiation across product lines.

Determining Costs: Analyzing Raw Materials and Labor

Batch pricing in soap making involves calculating the total cost of raw materials and labor for an entire batch, providing a comprehensive overview of production expenses, while per bar pricing breaks down these costs to determine the expense of producing each individual bar. Analyzing raw materials includes quantifying ingredients like oils, fragrances, and additives, and labor cost factors consider time spent on mixing, curing, and packaging. Accurate cost determination through both methods guides pricing strategies to ensure profitability and competitive market positioning.

Profitability Analysis: Batch vs Per Bar Models

Batch pricing in soap making allows for economies of scale by spreading fixed costs across a larger quantity, improving overall profitability when producing high volumes. Per bar pricing provides flexibility for small batches but can result in higher per-unit costs due to packaging, labor, and material expenses, potentially reducing profit margins. Analyzing cost components such as raw materials, labor, and overhead per batch versus per bar helps identify the most profitable pricing strategy based on production scale and market demand.

Scalability and Production Flexibility Considerations

Batch pricing in soap making enhances scalability by allowing producers to calculate costs based on entire production runs, reducing per-unit expenses as batch sizes increase. Per bar pricing offers greater production flexibility by enabling precise cost control and pricing adjustments for individual bars, which is ideal for custom or small-scale operations. Choosing between batch pricing and per bar pricing depends on balancing the need for scalable efficiency with adaptable production workflows.

Customer Perception and Pricing Strategies

Batch pricing in soap making offers customers a sense of value through bulk purchase discounts, encouraging larger orders and reducing per-unit costs. Per bar pricing aligns with customer expectations for transparency and simplicity, allowing precise cost comparison and immediate purchase decisions. Strategically, combining batch and per bar pricing can optimize revenue by catering to both budget-conscious buyers and those seeking convenience.

Choosing the Right Pricing Model for Your Soap Business

Choosing between batch pricing and per bar pricing involves analyzing production costs, time efficiency, and market demand for your soap business. Batch pricing offers simplicity and consistency, ideal for larger quantities and streamlined inventory management, while per bar pricing allows for flexibility, accommodating varied sizes and custom orders. Evaluating your target market, production scale, and cost structure ensures selecting the optimal pricing model to maximize profitability and customer satisfaction.

Batch Pricing vs Per Bar Pricing Infographic

bizdif.com

bizdif.com