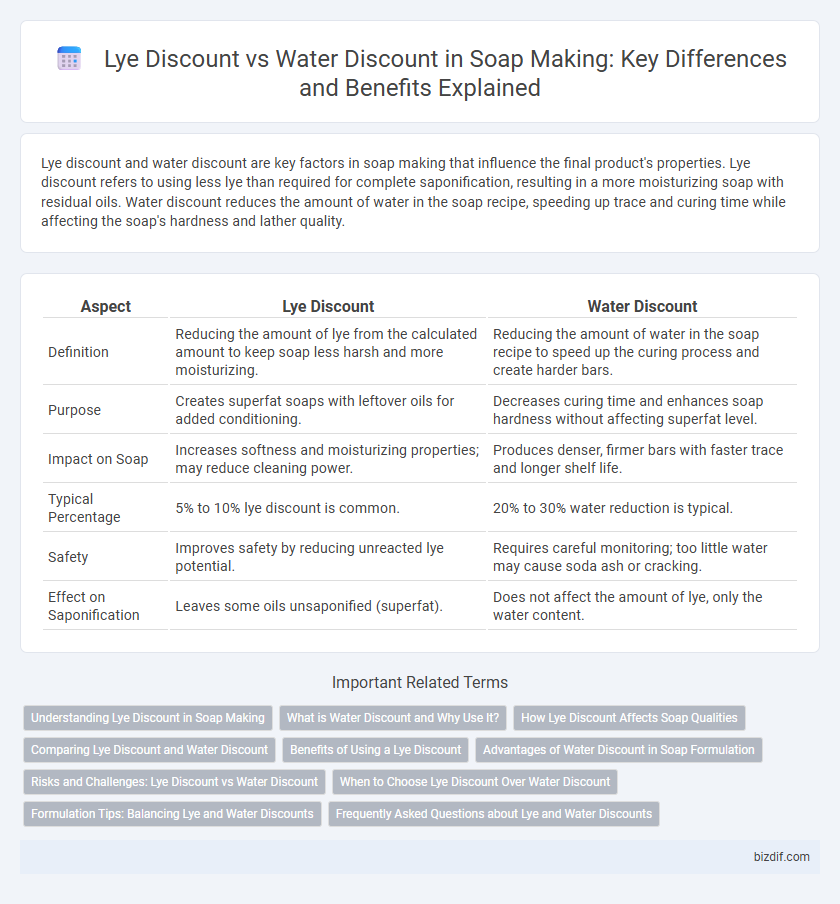

Lye discount and water discount are key factors in soap making that influence the final product's properties. Lye discount refers to using less lye than required for complete saponification, resulting in a more moisturizing soap with residual oils. Water discount reduces the amount of water in the soap recipe, speeding up trace and curing time while affecting the soap's hardness and lather quality.

Table of Comparison

| Aspect | Lye Discount | Water Discount |

|---|---|---|

| Definition | Reducing the amount of lye from the calculated amount to keep soap less harsh and more moisturizing. | Reducing the amount of water in the soap recipe to speed up the curing process and create harder bars. |

| Purpose | Creates superfat soaps with leftover oils for added conditioning. | Decreases curing time and enhances soap hardness without affecting superfat level. |

| Impact on Soap | Increases softness and moisturizing properties; may reduce cleaning power. | Produces denser, firmer bars with faster trace and longer shelf life. |

| Typical Percentage | 5% to 10% lye discount is common. | 20% to 30% water reduction is typical. |

| Safety | Improves safety by reducing unreacted lye potential. | Requires careful monitoring; too little water may cause soda ash or cracking. |

| Effect on Saponification | Leaves some oils unsaponified (superfat). | Does not affect the amount of lye, only the water content. |

Understanding Lye Discount in Soap Making

Lye discount in soap making refers to the intentional reduction of sodium hydroxide (lye) from the calculated amount needed for complete saponification, resulting in a more moisturizing bar by leaving excess oils unsaponified. This technique contrasts with water discount, which involves reducing water content to speed up trace without altering the lye ratio. Understanding lye discount is crucial for controlling the soap's hardness, cleansing properties, and skin feel, ensuring a balance between safety and desired moisturizing effects.

What is Water Discount and Why Use It?

Water discount in soap making refers to using less water than the typical recipe amount to create a thicker, harder soap bar with a shorter curing time. Reducing water improves the soap's consistency by limiting excess moisture, which helps prevent separation and accelerates saponification. This technique balances lye concentration and hydration levels, ensuring a more efficient chemical reaction and enhanced soap quality.

How Lye Discount Affects Soap Qualities

Lye discount directly influences soap qualities by controlling the amount of unreacted oils, which enhances moisturizing properties and reduces the soap's alkalinity, resulting in a gentler bar. Adjusting lye discount can impact hardness, lather creaminess, and curing time, with higher discounts producing softer, more conditioning soaps. Precise management of lye discount optimizes soap balance, improving user experience and product performance.

Comparing Lye Discount and Water Discount

Lye discount and water discount are crucial parameters in cold process soap making that influence the soap's hardness and curing time. Lye discount refers to reducing the amount of sodium hydroxide (lye) used, resulting in a softer, more moisturizing bar with some unsaponified oils, while water discount involves decreasing the water content to speed up trace and harden the soap faster without altering the chemical balance. Comparing both, lye discount directly affects saponification and soap qualities, whereas water discount primarily impacts the soap's drying and curing phases.

Benefits of Using a Lye Discount

Using a lye discount in soap making ensures a softer, more moisturizing bar by leaving extra un-reacted oils, which enhances skin hydration and mildness. This approach reduces the soap's alkalinity, decreasing the risk of irritation and making it suitable for sensitive skin. Lye discount also allows greater control over the final soap's texture and conditioning properties, improving the overall user experience.

Advantages of Water Discount in Soap Formulation

Water discount in soap formulation reduces the total water content, accelerating trace development and shortening cure time, which enhances production efficiency. It improves soap hardness and shelf life by limiting excess water that can weaken the final bar and cause longer drying periods. This approach also minimizes potential issues like soap softening or surface sweating, resulting in a more stable and durable product.

Risks and Challenges: Lye Discount vs Water Discount

Lye discount reduces the amount of sodium hydroxide, yielding a milder soap but increasing the risk of incomplete saponification, which can produce a soft or sticky bar prone to rancidity. Water discount decreases the water used in mixing, speeding up trace and reducing curing time, yet it can lead to overheating or false trace, causing inconsistent texture and difficulty in molding. Balancing lye and water discounts is critical to managing soap quality and safety, as excessive lye risks caustic soap while inadequate water compromises the chemical reaction and final product stability.

When to Choose Lye Discount Over Water Discount

Choosing lye discount over water discount is essential when aiming for a softer, more moisturizing soap with reduced alkalinity. Lye discount specifically reduces the amount of sodium hydroxide, ensuring excess oils remain in the final product for conditioning benefits. This method is preferred in formulations targeting sensitive skin or when incorporating delicate additives that may react adversely to high pH levels.

Formulation Tips: Balancing Lye and Water Discounts

Balancing lye discount and water discount is crucial for achieving optimal soap hardness and curing time in soap making. A higher lye discount reduces the amount of caustic soda, resulting in a milder soap, while adjusting water discount controls the soap's consistency and trace speed. Careful formulation ensures a stable saponification process, preventing separation or lye-heavy soap, and promoting a balanced texture and quality in the final product.

Frequently Asked Questions about Lye and Water Discounts

Lye discount in soap making refers to reducing the amount of lye below the full saponification value to create a milder, more moisturizing bar with excess oils remaining, while water discount involves using less water than standard recipes to speed up trace and curing time without altering the chemical balance. Frequently asked questions often address how lye discount affects soap hardness and cleansing properties versus how water discount influences the soap's texture and curing duration. Understanding both is crucial for customizing soap recipes to achieve desired qualities like gentleness, hardness, and curing speed.

Lye Discount vs Water Discount Infographic

bizdif.com

bizdif.com