Cold process soap making allows for precise control over ingredients and results in a smoother, more luxurious bar with longer curing time, enhancing its hardness and longevity. Hot process soap making speeds up saponification by applying heat, producing a soap that's ready to use sooner but often has a rustic texture due to the shorter curing period. Both methods use natural ingredients and lye but differ in time, texture, and final appearance, making each suitable for different preferences and crafting styles.

Table of Comparison

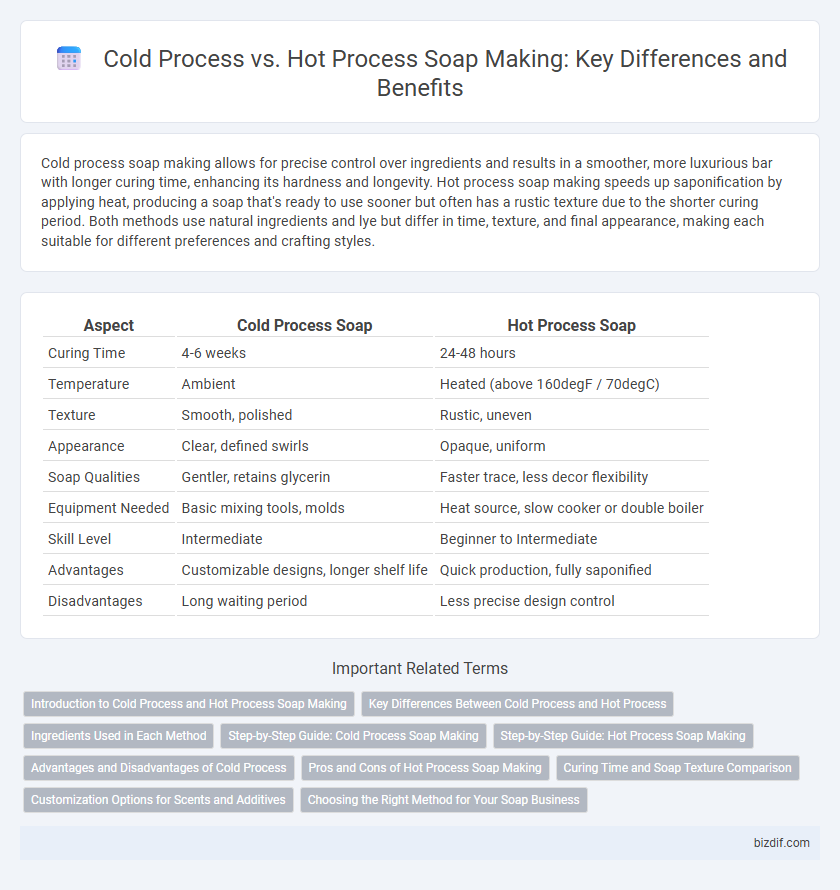

| Aspect | Cold Process Soap | Hot Process Soap |

|---|---|---|

| Curing Time | 4-6 weeks | 24-48 hours |

| Temperature | Ambient | Heated (above 160degF / 70degC) |

| Texture | Smooth, polished | Rustic, uneven |

| Appearance | Clear, defined swirls | Opaque, uniform |

| Soap Qualities | Gentler, retains glycerin | Faster trace, less decor flexibility |

| Equipment Needed | Basic mixing tools, molds | Heat source, slow cooker or double boiler |

| Skill Level | Intermediate | Beginner to Intermediate |

| Advantages | Customizable designs, longer shelf life | Quick production, fully saponified |

| Disadvantages | Long waiting period | Less precise design control |

Introduction to Cold Process and Hot Process Soap Making

Cold process soap making involves mixing oils and lye solution at room temperature, allowing saponification to occur slowly, resulting in a smooth, creamy bar with intricate designs. Hot process soap making uses external heat, often a slow cooker or double boiler, to accelerate saponification, producing a rustic, textured soap that can be used sooner. Both methods require precise measurements of lye and oils to ensure safety and effectiveness in the final soap product.

Key Differences Between Cold Process and Hot Process

Cold process soap making involves mixing oils and lye at lower temperatures, allowing the mixture to saponify slowly, resulting in a smoother, more customizable bar with a longer curing time of 4 to 6 weeks. Hot process uses heat to accelerate saponification, producing a rustic, ready-to-use soap within a few days, though it may have a denser texture due to the accelerated curing. Key differences include processing time, texture, and customization ability, with cold process favoring detailed design and hot process offering faster production.

Ingredients Used in Each Method

Cold process soap uses a precise blend of oils, lye, and water, allowing natural oils like olive, coconut, and palm to retain their beneficial properties through saponification at lower temperatures. Hot process soap incorporates similar oils but involves cooking the mixture, which accelerates saponification and allows for the inclusion of additives like clays, herbs, and exfoliants without degradation. Both methods rely on sodium hydroxide as the lye source, but temperature control in cold process preserves delicate ingredients, while hot process offers faster curing and durability in the final soap.

Step-by-Step Guide: Cold Process Soap Making

Cold process soap making involves combining oils and lye to create saponification without external heat, preserving natural glycerin and beneficial properties. The step-by-step guide includes measuring and mixing lye with water, blending oils to a specific temperature, slowly combining lye solution with oils while stirring to trace, adding desired additives like essential oils or colorants, then pouring the batter into molds for 24-48 hours of curing. This method requires a curing time of 4-6 weeks to fully harden and become mild, ensuring a long-lasting, moisturizing bar.

Step-by-Step Guide: Hot Process Soap Making

Hot process soap making involves cooking the soap batter at a controlled temperature to accelerate saponification, resulting in a thicker and more gelled mixture. This method requires adding lye and oils, mixing to trace, then transferring the batter to a slow cooker or double boiler where it cooks for 1-3 hours with periodic stirring. After cooking, the soap is poured into molds and allowed to cure for 1-2 weeks, producing a milder and ready-to-use bar compared to the longer curing time needed for cold process soap.

Advantages and Disadvantages of Cold Process

Cold process soap making preserves natural glycerin, resulting in a moisturizing bar with intricate design possibilities. The long curing time, typically 4-6 weeks, allows excess water to evaporate, creating a harder and longer-lasting soap but requires patience and careful control of ingredients. Sensitivity to temperature fluctuations and potential lye trace inconsistencies are challenges that may impact the final product's texture and quality.

Pros and Cons of Hot Process Soap Making

Hot process soap making offers the advantage of faster curing time, allowing soap to be used within a week, which is significantly shorter than cold process soaps that require 4-6 weeks. This method benefits from the heat accelerating saponification, resulting in a sturdier, more rustic texture that can be molded or cut immediately after cooking. However, hot process soaps may have a rougher appearance and slightly less vibrant colors compared to cold process soaps, which preserve more delicate fragrances and designs due to their slower curing process.

Curing Time and Soap Texture Comparison

Cold process soap requires a curing time of 4 to 6 weeks, allowing excess water to evaporate and resulting in a harder, longer-lasting bar with a smooth, creamy texture. Hot process soap has a significantly shorter curing time, typically 1 to 2 weeks, due to the accelerated saponification from heat, producing a rustic, textured finish that is ready for use sooner. The extended curing period of cold process soap enhances longevity and lather quality, while hot process soap offers quick turnaround and a more natural, uneven texture.

Customization Options for Scents and Additives

Cold process soap making offers greater customization options for scents and additives since essential oils and delicate botanicals can be incorporated at lower temperatures, preserving their aromatic and therapeutic properties. Hot process soap involves higher heat, which can diminish the potency of fragrances and sensitive additives, limiting customization flexibility. For artisans seeking precise control over scent profiles and ingredient integrity, cold process remains the preferred method.

Choosing the Right Method for Your Soap Business

Cold process soap offers greater control over ingredient customization and results in a smoother, more refined texture, making it ideal for artisan soap businesses aiming for aesthetic appeal. Hot process soap cures faster and is more forgiving with additives, suitable for businesses needing quicker production turnaround and robust, rustic bars. Evaluating your target market's preference, production timeline, and ingredient flexibility will guide the optimal method selection for scalable soap business success.

Cold Process vs Hot Process Infographic

bizdif.com

bizdif.com