Traditional curing in pet soap making involves air-drying the bars for several weeks, allowing the soap to harden naturally and achieve a gentle, long-lasting lather that is safe for sensitive animal skin. Forced curing speeds up this process using heat or humidity controls to reduce drying time, but it may compromise the soap's texture and mildness, which are critical for pets. Choosing between traditional and forced curing impacts the quality, shelf life, and overall safety of the pet soap.

Table of Comparison

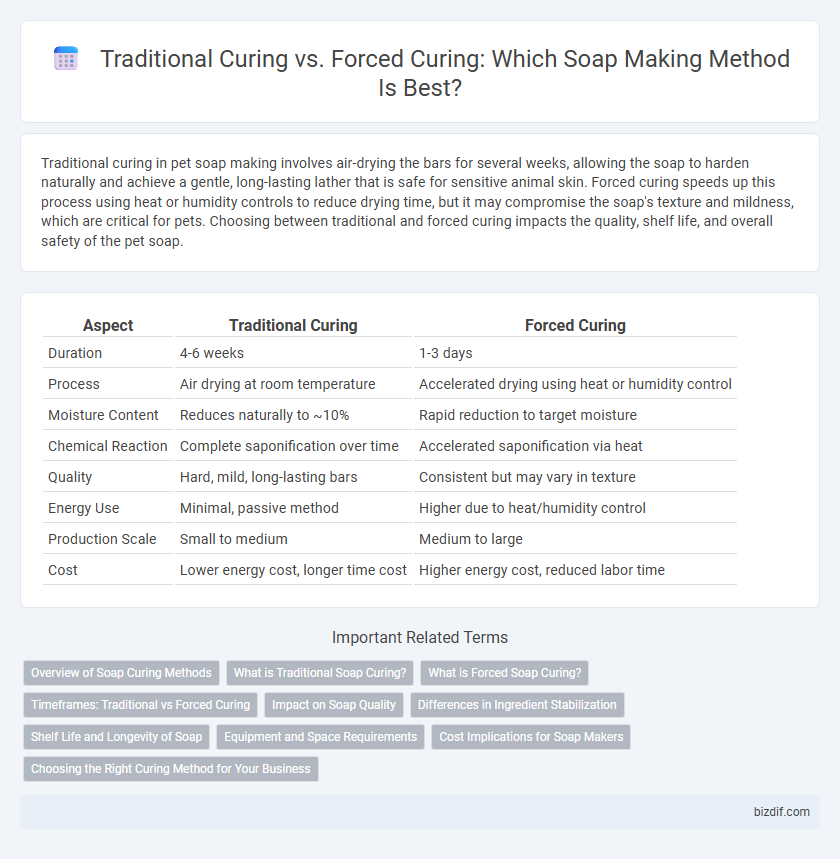

| Aspect | Traditional Curing | Forced Curing |

|---|---|---|

| Duration | 4-6 weeks | 1-3 days |

| Process | Air drying at room temperature | Accelerated drying using heat or humidity control |

| Moisture Content | Reduces naturally to ~10% | Rapid reduction to target moisture |

| Chemical Reaction | Complete saponification over time | Accelerated saponification via heat |

| Quality | Hard, mild, long-lasting bars | Consistent but may vary in texture |

| Energy Use | Minimal, passive method | Higher due to heat/humidity control |

| Production Scale | Small to medium | Medium to large |

| Cost | Lower energy cost, longer time cost | Higher energy cost, reduced labor time |

Overview of Soap Curing Methods

Traditional curing involves air-drying soap bars for 4 to 6 weeks, allowing excess water to evaporate and the saponification process to complete naturally, resulting in harder, longer-lasting soap. Forced curing accelerates this process using heat or ovens, reducing curing time to a few days but potentially affecting soap texture and longevity. Both methods influence soap hardness, shelf life, and moisture content, with traditional curing generally producing a milder, longer-lasting product.

What is Traditional Soap Curing?

Traditional soap curing is a natural drying process lasting 4 to 6 weeks, allowing excess water to evaporate and the soap to harden. This method enhances the soap's mildness, lather quality, and longevity by enabling saponification to complete fully. Maintaining proper airflow and temperature during traditional curing is essential to prevent moisture retention and achieve optimal soap durability.

What is Forced Soap Curing?

Forced soap curing is an accelerated process that uses controlled heat and humidity to speed up the saponification and drying phases, reducing cure time from weeks to days. This method involves placing soap in a warm environment, often between 110degF and 140degF, to expedite lye neutralization and moisture evaporation. While traditional curing enhances soap hardness and mildness through gradual water loss, forced curing prioritizes efficiency, often at the expense of some quality attributes.

Timeframes: Traditional vs Forced Curing

Traditional soap curing typically requires 4 to 6 weeks to allow saponification to complete and excess moisture to evaporate, resulting in a harder, longer-lasting bar. Forced curing accelerates this process, reducing curing time to 1 to 2 weeks by applying heat or controlled airflow, but may yield a softer soap that can affect longevity. Timeframes between traditional and forced curing directly impact the soap's texture, hardness, and overall maturity.

Impact on Soap Quality

Traditional curing enhances soap quality by allowing slow saponification and water evaporation over 4 to 6 weeks, resulting in a harder, milder bar with superior lather and longer shelf life. Forced curing accelerates the process through heat or pressure, producing soap in days but often compromising hardness, causing a softer texture and potentially harsher skin feel. The choice between curing methods directly affects soap durability, cleansing efficiency, and skin compatibility.

Differences in Ingredient Stabilization

Traditional curing in soap making relies on natural evaporation over several weeks, allowing moisture to gradually leave the soap and enabling ingredient stabilization through slow saponification and salt crystallization. Forced curing accelerates this process using elevated temperatures or microwave ovens, which can lead to quicker moisture removal but may cause incomplete ingredient stabilization and potential degradation of sensitive additives like essential oils. The difference in curing methods directly impacts the final soap hardness, lather quality, and shelf life due to these variations in ingredient stabilization efficiency.

Shelf Life and Longevity of Soap

Traditional curing involves air-drying soap for 4 to 6 weeks, allowing excess water to evaporate and resulting in a harder, longer-lasting bar with improved shelf life. Forced curing accelerates this process using heat or humidity control, reducing curing time to days but potentially compromising the soap's durability and reducing its effective lifespan. Soaps cured traditionally tend to maintain their integrity and lather quality over extended periods compared to those subjected to forced curing methods.

Equipment and Space Requirements

Traditional curing requires minimal equipment, relying primarily on well-ventilated racks or shelves and ample space for soap bars to air-dry over 4 to 6 weeks. Forced curing involves specialized equipment such as curing chambers or drying ovens that control temperature and humidity, significantly reducing the curing time to a few days. Space requirements are more compact for forced curing systems but demand electrical power and investment in engineered setups.

Cost Implications for Soap Makers

Traditional curing requires longer drying times, increasing storage costs and tying up capital, while forced curing accelerates soap hardening through heat or humidity, reducing storage duration but raising energy expenses. Soap makers must balance lower overhead from faster turnaround against higher utility bills associated with forced curing methods. Cost efficiency depends on production scale, with traditional curing being more economical for small batches and forced curing benefiting large-scale operations through quicker inventory cycling.

Choosing the Right Curing Method for Your Business

Selecting the ideal curing method for your soap business depends on factors such as production scale, time constraints, and product quality. Traditional curing, requiring 4-6 weeks, ensures thorough saponification and a harder bar, benefiting artisanal and small-batch makers. Forced curing, using heat and humidity control, accelerates turnaround to days, ideal for mass production but may compromise soap hardness and longevity.

Traditional Curing vs Forced Curing Infographic

bizdif.com

bizdif.com