Melt and Pour soap making offers simplicity and speed, using pre-made soap bases that are melted, customized, and solidified without curing time, ideal for beginners and quick projects. Cold Process involves mixing oils and lye, allowing saponification to occur naturally, creating a more customizable and durable soap but requiring patience for curing and safety precautions. Choosing between Melt and Pour and Cold Process depends on desired control, time commitment, and skill level in soap making.

Table of Comparison

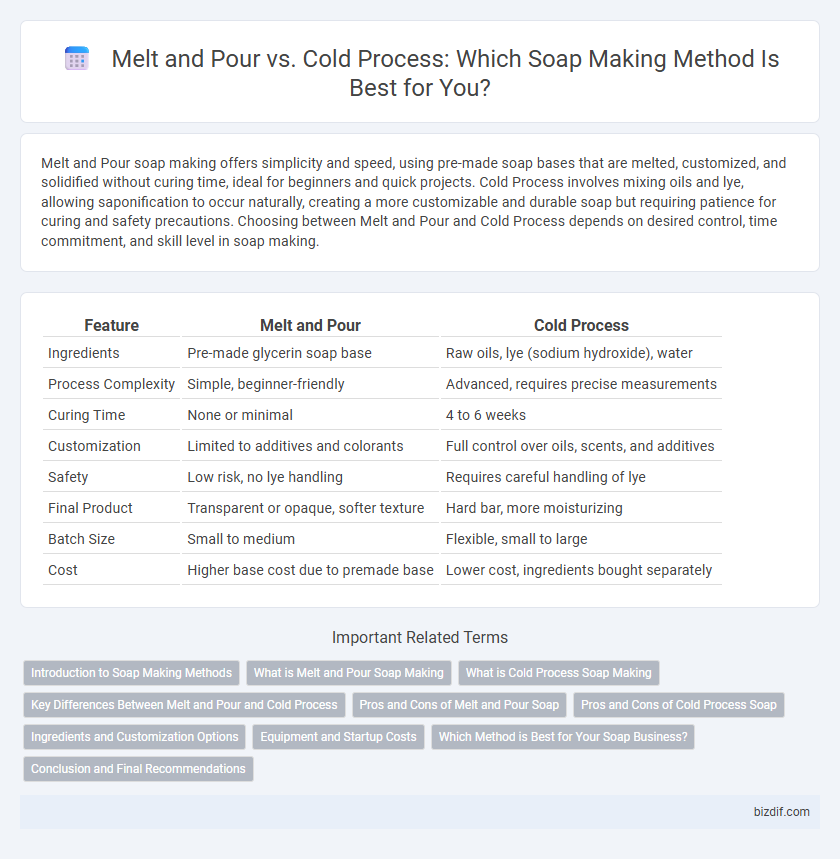

| Feature | Melt and Pour | Cold Process |

|---|---|---|

| Ingredients | Pre-made glycerin soap base | Raw oils, lye (sodium hydroxide), water |

| Process Complexity | Simple, beginner-friendly | Advanced, requires precise measurements |

| Curing Time | None or minimal | 4 to 6 weeks |

| Customization | Limited to additives and colorants | Full control over oils, scents, and additives |

| Safety | Low risk, no lye handling | Requires careful handling of lye |

| Final Product | Transparent or opaque, softer texture | Hard bar, more moisturizing |

| Batch Size | Small to medium | Flexible, small to large |

| Cost | Higher base cost due to premade base | Lower cost, ingredients bought separately |

Introduction to Soap Making Methods

Melt and Pour soap making involves melting a pre-made glycerin soap base and adding colors, scents, and additives before pouring it into molds, offering a quick and beginner-friendly approach. Cold Process soap making combines oils and lye through saponification, allowing for greater customization in ingredients and design but requiring curing time of 4 to 6 weeks. Both methods provide unique advantages in creativity and control, appealing to hobbyists and professional soap makers alike.

What is Melt and Pour Soap Making

Melt and Pour soap making involves heating pre-made glycerin soap bases until melted, then mixing in colors, fragrances, and additives before pouring into molds to set. This method offers a quick, beginner-friendly process without requiring handling of lye, unlike cold process soap making which involves saponification from scratch. Melt and Pour soap provides consistent results and allows for extensive customization with embedments and swirls.

What is Cold Process Soap Making

Cold process soap making involves combining oils and lye to trigger saponification, creating a natural, handcrafted bar with customizable ingredients and textures. Unlike melt and pour, cold process requires curing time of 4 to 6 weeks for the soap to harden and become safe for use. This method allows full control over oil blends, additives like essential oils, and natural colorants, resulting in a highly personalized soap product.

Key Differences Between Melt and Pour and Cold Process

Melt and Pour soap uses a pre-made base that is melted and customized with fragrances and colors, offering quick and easy soap creation without handling lye. Cold Process soap involves combining oils and lye, initiating saponification and requiring curing for 4-6 weeks to develop hardness and mildness. Key differences include preparation time, control over ingredients, and the need for safety precautions when handling lye during the Cold Process method.

Pros and Cons of Melt and Pour Soap

Melt and Pour soap offers the advantage of convenience and safety, as it bypasses the need to handle lye, making it ideal for beginners and quick projects. This method allows for easy customization with colors, scents, and additives without curing time, enabling immediate use or gifting. However, Melt and Pour soap often lacks the natural glycerin retention of cold process soap and can be less durable or produce a softer bar, limiting its longevity compared to cold-processed alternatives.

Pros and Cons of Cold Process Soap

Cold process soap offers full control over ingredients, allowing customization for sensitive skin and specific needs, but it requires curing time of 4-6 weeks before use. This method produces a harder, longer-lasting bar with a natural glycerin content, though it involves handling lye, which demands safety precautions and experience. Compared to melt and pour, cold process soap provides superior durability and ingredient flexibility but requires more time, skill, and careful handling during production.

Ingredients and Customization Options

Melt and Pour soap bases consist of pre-made glycerin soap that allows the addition of colors, fragrances, and additives without the need for handling lye, making customization straightforward and safe for beginners. Cold Process soap requires combining precise amounts of oils and lye, enabling full control over the soap's ingredients, scents, and textures but demands careful measurement and curing time for chemical reactions to complete. While Melt and Pour offers convenience and quick customization, Cold Process provides deeper ingredient control and the ability to tailor soap properties such as hardness and moisturizing qualities.

Equipment and Startup Costs

Melt and pour soap making requires minimal equipment such as a microwave or double boiler and simple molds, resulting in low startup costs typically under $100. Cold process soap making demands specialized tools including a digital scale, stick blender, safety gear, and curing racks, increasing initial expenses to around $150-$300. Both methods offer scalable options, but cold process entails more investment due to ingredient handling and longer curing times.

Which Method is Best for Your Soap Business?

Melt and Pour soap making offers quick production with pre-made bases, ideal for beginners and small-scale businesses seeking customization without handling lye. Cold Process requires more skill, using raw ingredients and a curing period, resulting in higher-quality, long-lasting bars favored by artisans and luxury brands. Choosing the best method depends on your business goals, production scale, and desired product quality.

Conclusion and Final Recommendations

Melt and Pour soap making offers simplicity and quick results ideal for beginners or small batches, while Cold Process requires more skill but allows for greater customization and control over ingredients. For artisanal quality and long-lasting bars, Cold Process is recommended, though Melt and Pour serves well for fast, decorative projects. Choosing between methods depends on the desired outcome, available time, and hands-on experience in soap crafting.

Melt and Pour vs Cold Process Infographic

bizdif.com

bizdif.com