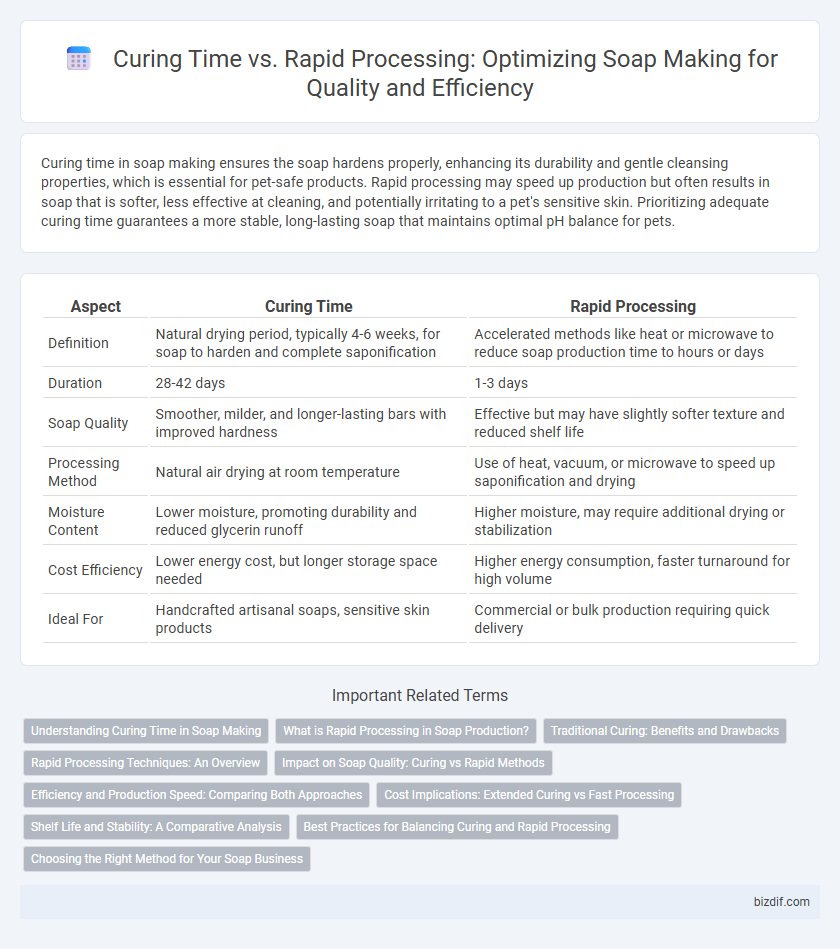

Curing time in soap making ensures the soap hardens properly, enhancing its durability and gentle cleansing properties, which is essential for pet-safe products. Rapid processing may speed up production but often results in soap that is softer, less effective at cleaning, and potentially irritating to a pet's sensitive skin. Prioritizing adequate curing time guarantees a more stable, long-lasting soap that maintains optimal pH balance for pets.

Table of Comparison

| Aspect | Curing Time | Rapid Processing |

|---|---|---|

| Definition | Natural drying period, typically 4-6 weeks, for soap to harden and complete saponification | Accelerated methods like heat or microwave to reduce soap production time to hours or days |

| Duration | 28-42 days | 1-3 days |

| Soap Quality | Smoother, milder, and longer-lasting bars with improved hardness | Effective but may have slightly softer texture and reduced shelf life |

| Processing Method | Natural air drying at room temperature | Use of heat, vacuum, or microwave to speed up saponification and drying |

| Moisture Content | Lower moisture, promoting durability and reduced glycerin runoff | Higher moisture, may require additional drying or stabilization |

| Cost Efficiency | Lower energy cost, but longer storage space needed | Higher energy consumption, faster turnaround for high volume |

| Ideal For | Handcrafted artisanal soaps, sensitive skin products | Commercial or bulk production requiring quick delivery |

Understanding Curing Time in Soap Making

Curing time in soap making is essential for allowing excess water to evaporate, resulting in a harder, longer-lasting bar with improved lather and gentler cleansing properties. Rushing the process through rapid processing methods often compromises the soap's texture, durability, and skin benefits, leading to a softer, less stable product. Proper curing, typically spanning 4 to 6 weeks, enhances saponification completion and ensures balanced moisture content for optimal soap performance.

What is Rapid Processing in Soap Production?

Rapid processing in soap production refers to techniques that significantly shorten the traditional curing time, which typically spans 4 to 6 weeks. Methods such as heat curing, microwave curing, or using additives like accelerators enable soaps to harden and mature faster while maintaining quality. This process enhances production efficiency by allowing quicker packaging and sales without compromising the soap's cleansing properties or shelf life.

Traditional Curing: Benefits and Drawbacks

Traditional curing in soap making involves a prolonged period, typically 4 to 6 weeks, allowing the soap to harden and excess moisture to evaporate for a milder, longer-lasting bar. This slow curing process enhances the soap's texture, improves lather quality, and ensures complete saponification, reducing skin irritation risks. However, the extended curing time can limit production speed and increase storage needs, posing challenges for high-volume or rapid processing demands.

Rapid Processing Techniques: An Overview

Rapid processing techniques in soap making dramatically reduce curing time by utilizing methods such as hot process and microwave curing, which accelerate saponification and drying. These techniques maintain soap quality while shortening the traditional 4-6 weeks curing period to just a few hours or days. Using controlled heat and specialized equipment, rapid curing ensures consistent texture, hardness, and longevity without compromising the soap's cleansing properties.

Impact on Soap Quality: Curing vs Rapid Methods

Extended curing time in soap making allows complete saponification and moisture evaporation, resulting in a harder, longer-lasting bar with improved lather and skin conditioning. Rapid processing methods, such as hot process or microwave techniques, shorten curing time but may yield softer soap with higher moisture content and potentially less refined texture. The quality impact favors traditional curing for superior durability and mildness, while rapid methods prioritize faster production at some expense to soap longevity and finish.

Efficiency and Production Speed: Comparing Both Approaches

Curing time in soap making enhances product hardness, longevity, and skin benefits by allowing saponification to complete fully, though it requires several weeks and limits production speed. Rapid processing methods, such as hot process soap making, accelerate saponification through external heat, significantly reducing curing time to days but may sacrifice some texture refinement and mildness. Balancing curing time and rapid processing depends on production goals, with traditional curing favoring quality and shelf life, while rapid methods optimize efficiency and faster market availability.

Cost Implications: Extended Curing vs Fast Processing

Extended curing in soap making increases production time and inventory costs but results in a harder, longer-lasting bar that reduces customer complaints and returns. Rapid processing techniques lower upfront labor and storage expenses by shortening the curing period but may compromise soap quality, leading to potential product inconsistencies and higher defect rates. Balancing curing time and processing speed directly impacts cost efficiency, product durability, and customer satisfaction in soap manufacturing.

Shelf Life and Stability: A Comparative Analysis

Curing time in soap making enhances shelf life by allowing excess water to evaporate, resulting in a harder, more stable bar resistant to degradation and microbial growth. Rapid processing, while faster, often produces softer soap with higher moisture content, leading to reduced stability and a shorter shelf life due to accelerated rancidity. Optimal curing, typically 4 to 6 weeks, balances moisture reduction and saponification completion, ensuring maximum longevity and consistent product quality.

Best Practices for Balancing Curing and Rapid Processing

Balancing curing time with rapid processing in soap making requires maintaining a minimum 4 to 6 weeks curing period to ensure saponification completes and excess moisture evaporates, resulting in a harder, longer-lasting bar. Utilizing accelerated curing techniques such as heat curing or embedding curing racks in a controlled environment with optimal humidity (45%-60%) and temperature (60-70degF) can reduce curing time without compromising soap quality. Careful monitoring of pH levels and texture throughout the curing process supports best practices for achieving a safe, gentle, and durable soap product.

Choosing the Right Method for Your Soap Business

Curing time impacts the hardness, longevity, and safety of handmade soap, with traditional cold process methods requiring 4 to 6 weeks for optimal results. Rapid processing techniques, such as hot process or melt and pour, significantly reduce production time but may affect texture and quality consistency. Choosing the right method depends on balancing product quality with business scalability, customer demand, and production capacity.

Curing Time vs Rapid Processing Infographic

bizdif.com

bizdif.com