Batch production in bakeries involves producing goods in specific, limited quantities, allowing for flexibility in recipe adjustments and variety. Continuous production operates nonstop, optimizing efficiency and consistency, particularly suitable for large-scale operations with stable product demand. Choosing between the two depends on factors like product type, volume requirements, and customization needs.

Table of Comparison

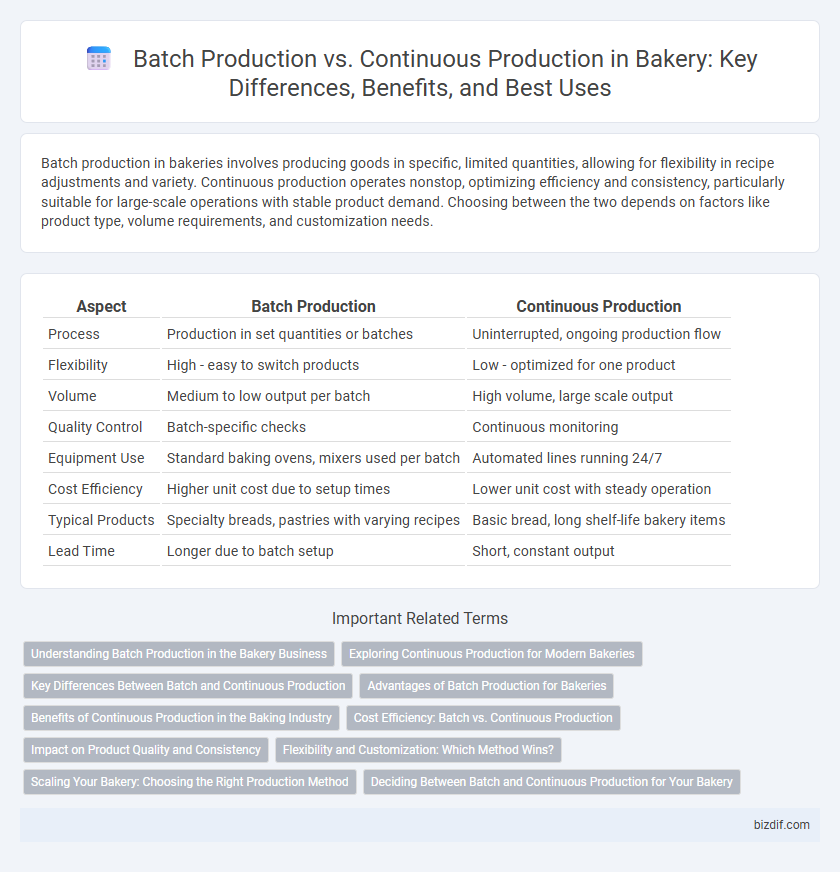

| Aspect | Batch Production | Continuous Production |

|---|---|---|

| Process | Production in set quantities or batches | Uninterrupted, ongoing production flow |

| Flexibility | High - easy to switch products | Low - optimized for one product |

| Volume | Medium to low output per batch | High volume, large scale output |

| Quality Control | Batch-specific checks | Continuous monitoring |

| Equipment Use | Standard baking ovens, mixers used per batch | Automated lines running 24/7 |

| Cost Efficiency | Higher unit cost due to setup times | Lower unit cost with steady operation |

| Typical Products | Specialty breads, pastries with varying recipes | Basic bread, long shelf-life bakery items |

| Lead Time | Longer due to batch setup | Short, constant output |

Understanding Batch Production in the Bakery Business

Batch production in the bakery business involves producing baked goods in specific quantities or lots, allowing for greater control over quality and ingredient variations. This method is ideal for specialty or seasonal products where customization and freshness are essential. Batch production enhances flexibility in recipe adjustments and inventory management, reducing waste and aligning output with demand fluctuations.

Exploring Continuous Production for Modern Bakeries

Continuous production in modern bakeries enhances efficiency by maintaining an uninterrupted flow of dough mixing, baking, and packaging, significantly reducing downtime compared to traditional batch production. Automated systems enable precise control of ingredient dosing and oven temperature, ensuring consistent product quality and meeting high-volume demand. Investing in continuous production technology supports scalability and sustainability by minimizing waste and energy consumption while improving overall profitability.

Key Differences Between Batch and Continuous Production

Batch production in bakeries involves producing goods in specific quantities or batches, allowing flexibility and customization for different recipes or seasonal items. Continuous production operates non-stop, optimizing efficiency and uniformity for high-volume items like mass-produced bread or rolls. Key differences include batch production's adaptability to product variety versus continuous production's emphasis on speed and consistent quality.

Advantages of Batch Production for Bakeries

Batch production in bakeries allows for flexible recipe adjustments and customization, meeting varying customer demands efficiently. It minimizes waste by producing specific quantities that align with seasonal trends or special orders, enhancing inventory management. This method also improves quality control by isolating batches, making it easier to identify and address production issues promptly.

Benefits of Continuous Production in the Baking Industry

Continuous production in the baking industry maximizes efficiency by enabling consistent dough mixing, proofing, and baking processes with minimal downtime. This method ensures uniform product quality and reduces labor costs through automation and streamlined workflows. Enhanced capacity to meet high demand makes continuous production ideal for large-scale bakeries aiming to increase output while maintaining product standards.

Cost Efficiency: Batch vs. Continuous Production

Batch production in bakeries offers flexibility and lower initial investment, making it cost-efficient for small to medium-scale operations with varied product lines. Continuous production delivers higher cost efficiency for large-scale bakeries by minimizing labor costs and reducing material waste through automation and steady workflow. Choosing between batch and continuous production depends on volume demands, with continuous systems optimizing economies of scale and batch systems enhancing product variety.

Impact on Product Quality and Consistency

Batch production in bakery allows for precise control over ingredient mixing and baking time, resulting in high product quality and consistency within each batch. Continuous production optimizes efficiency and output but may face challenges in maintaining uniformity due to nonstop processing and potential ingredient variation. Consistent monitoring and automation are essential in continuous production to sustain product quality comparable to batch methods.

Flexibility and Customization: Which Method Wins?

Batch production in a bakery offers greater flexibility and customization by allowing adjustments to recipes and quantities between batches, ideal for seasonal or specialty breads. Continuous production excels in high-volume consistency but limits the ability to alter product variety quickly. For bakeries prioritizing diverse product lines and frequent recipe changes, batch production clearly wins in flexibility and customization.

Scaling Your Bakery: Choosing the Right Production Method

Batch production allows bakeries to focus on small, customizable runs of products, making it ideal for artisanal or seasonal items that require adjustment and quality control. Continuous production excels in scaling operations for high-demand baked goods, offering consistent output and efficiency through automated processes. Selecting the right production method depends on factors like product variety, order volume, and desired flexibility in bakery operations.

Deciding Between Batch and Continuous Production for Your Bakery

Batch production in a bakery allows for flexibility in creating diverse products like bread, pastries, and cakes in smaller quantities, ideal for customization and seasonal variations. Continuous production suits bakeries with high demand and standardized products, optimizing efficiency by running uninterrupted baking and packaging processes. Evaluating factors such as product variety, order volume, equipment investment, and production speed helps determine whether batch or continuous production best meets your bakery's operational goals.

Batch Production vs Continuous Production Infographic

bizdif.com

bizdif.com