In-store baking offers fresher products with appealing aromas that attract customers directly within the bakery, enhancing the shopping experience. Central kitchen baking streamlines production, ensuring consistent quality and cost efficiency by preparing baked goods in bulk before distribution. Balancing these methods allows bakeries to optimize freshness and operational efficiency while meeting customer demand.

Table of Comparison

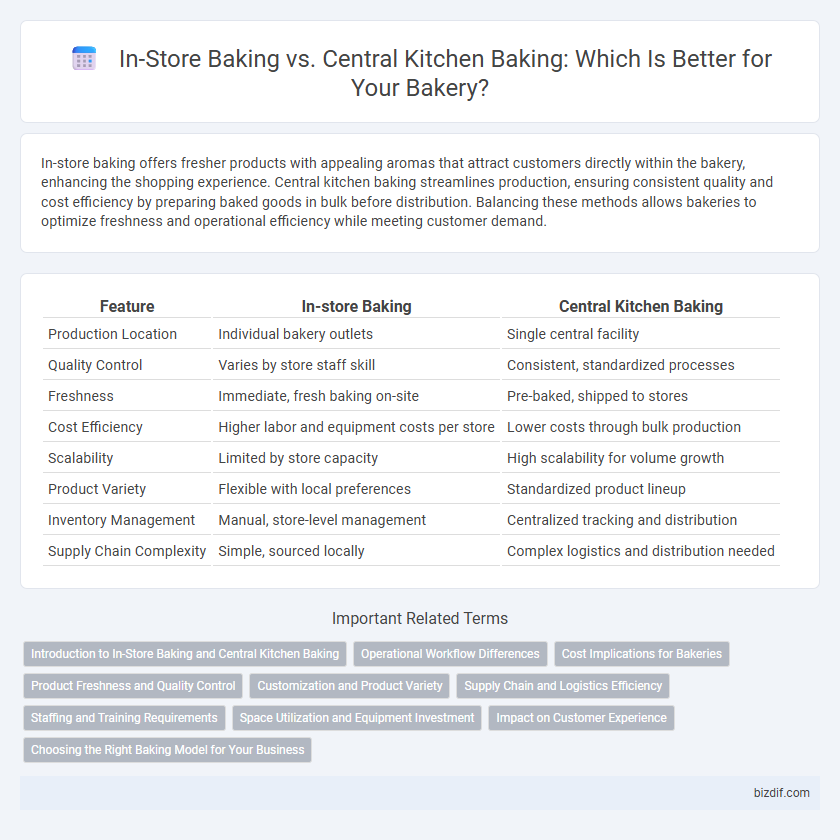

| Feature | In-store Baking | Central Kitchen Baking |

|---|---|---|

| Production Location | Individual bakery outlets | Single central facility |

| Quality Control | Varies by store staff skill | Consistent, standardized processes |

| Freshness | Immediate, fresh baking on-site | Pre-baked, shipped to stores |

| Cost Efficiency | Higher labor and equipment costs per store | Lower costs through bulk production |

| Scalability | Limited by store capacity | High scalability for volume growth |

| Product Variety | Flexible with local preferences | Standardized product lineup |

| Inventory Management | Manual, store-level management | Centralized tracking and distribution |

| Supply Chain Complexity | Simple, sourced locally | Complex logistics and distribution needed |

Introduction to In-Store Baking and Central Kitchen Baking

In-store baking involves preparing and baking products directly within the retail bakery, ensuring fresh items and immediate availability for customers. Central kitchen baking centralizes production in a dedicated facility, enabling large-scale batch processing and consistent product quality across multiple retail locations. Both methods impact operational efficiency, product freshness, and customer experience differently in the bakery industry.

Operational Workflow Differences

In-store baking requires a decentralized operational workflow where dough preparation, proofing, and baking occur on-site, allowing for fresh product customization and immediate customer service. Central kitchen baking employs a centralized workflow with bulk production of dough and par-baked goods that are transported to retail locations for final baking and display, optimizing consistency and reducing labor at stores. These operational differences impact inventory management, resource allocation, and delivery scheduling, influencing overall bakery efficiency and product freshness.

Cost Implications for Bakeries

In-store baking often incurs higher labor and utility costs due to the need for skilled bakers and multiple ovens operating simultaneously, leading to increased overhead expenses for each store location. Central kitchen baking benefits from economies of scale, reducing ingredient procurement and production costs by consolidating operations in a single facility. However, additional expenses such as transportation and product freshness must be managed to maintain cost-efficiency and product quality across bakery outlets.

Product Freshness and Quality Control

In-store baking ensures product freshness by allowing baked goods to be prepared and sold within hours, preserving optimal texture and flavor. Central kitchen baking offers stringent quality control through standardized processes and centralized ingredient sourcing but may sacrifice immediacy, potentially affecting freshness upon delivery. Balancing in-store baking with central kitchen production can optimize product quality and freshness, meeting customer expectations effectively.

Customization and Product Variety

In-store baking allows bakeries to customize products on-site, offering fresh, diverse items tailored to local customer preferences, which enhances product variety and meets specific dietary needs. Central kitchen baking streamlines operations by producing large batches of standardized goods, ensuring consistent quality but limiting customization and variety at individual store locations. Balancing in-store baking with central kitchen production enables bakeries to optimize both product variety and operational efficiency, catering to broad customer demands while maintaining brand consistency.

Supply Chain and Logistics Efficiency

In-store baking allows fresh products to be made on demand, reducing transportation costs and minimizing the need for complex cold chain logistics. Central kitchen baking streamlines production by consolidating resources, enabling bulk ingredient purchasing and consistent quality control, though it requires efficient distribution networks to ensure timely delivery. Supply chain management for central kitchens emphasizes coordinated inventory flow and optimized route planning to balance freshness with operational scalability.

Staffing and Training Requirements

In-store baking requires a larger, versatile team skilled in various baking techniques to ensure freshness and customization, with ongoing training focused on product consistency and customer interaction. Central kitchen baking demands specialized staff proficient in large-scale production processes and stringent quality control, emphasizing efficiency and standardization during training. Staffing for in-store operations often involves cross-trained employees, while central kitchens prioritize technical expertise and strict adherence to production schedules.

Space Utilization and Equipment Investment

In-store baking requires dedicated space for ovens, proofers, and prep areas, limiting retail display and customer flow but enabling fresh product presentation. Central kitchen baking consolidates equipment and production in one location, optimizing space in individual stores and reducing the need for multiple high-cost appliances. Investment in a central kitchen yields economies of scale, while in-store baking demands capital for dispersed equipment and higher real estate usage per location.

Impact on Customer Experience

In-store baking enhances customer experience by providing fresh aromas and a visually appealing environment that encourages impulse purchases and builds trust in product quality. Central kitchen baking ensures consistent product quality and streamlines operations but may lack the sensory engagement that draws customers closer to the bakery. Choosing between the two methods directly influences customer satisfaction, brand perception, and repeat business.

Choosing the Right Baking Model for Your Business

Choosing the right baking model depends on your bakery's scale, product variety, and customer demand. In-store baking offers freshness and customization, enhancing customer experience and immediate product turnover. Central kitchen baking streamlines production, reduces costs, and ensures consistent quality across multiple locations, making it ideal for expanding bakery chains.

In-store Baking vs Central Kitchen Baking Infographic

bizdif.com

bizdif.com