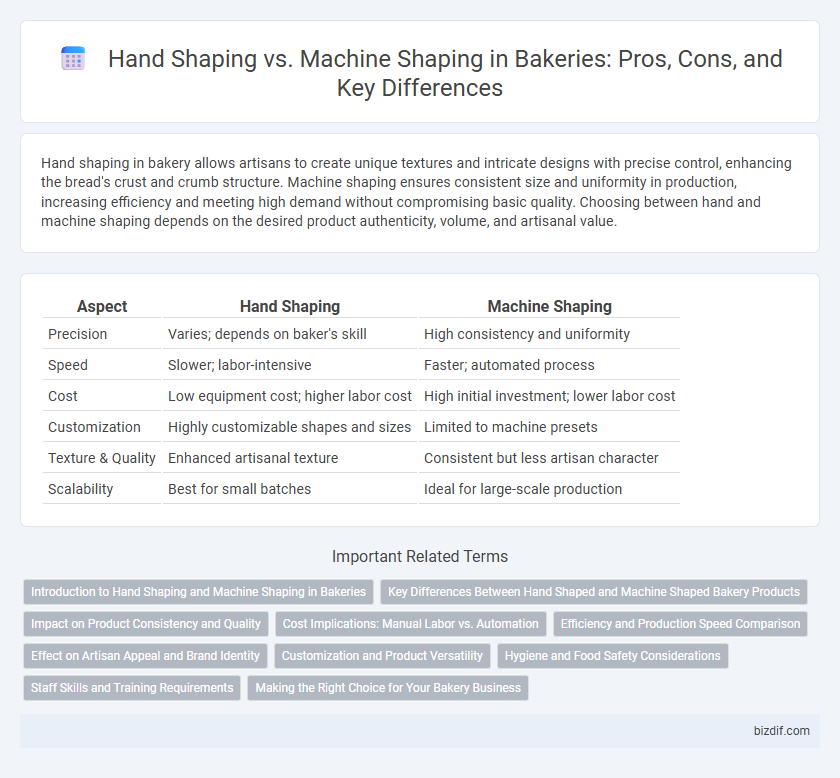

Hand shaping in bakery allows artisans to create unique textures and intricate designs with precise control, enhancing the bread's crust and crumb structure. Machine shaping ensures consistent size and uniformity in production, increasing efficiency and meeting high demand without compromising basic quality. Choosing between hand and machine shaping depends on the desired product authenticity, volume, and artisanal value.

Table of Comparison

| Aspect | Hand Shaping | Machine Shaping |

|---|---|---|

| Precision | Varies; depends on baker's skill | High consistency and uniformity |

| Speed | Slower; labor-intensive | Faster; automated process |

| Cost | Low equipment cost; higher labor cost | High initial investment; lower labor cost |

| Customization | Highly customizable shapes and sizes | Limited to machine presets |

| Texture & Quality | Enhanced artisanal texture | Consistent but less artisan character |

| Scalability | Best for small batches | Ideal for large-scale production |

Introduction to Hand Shaping and Machine Shaping in Bakeries

Hand shaping in bakeries involves skilled artisans manually molding dough to create unique textures and traditional bread shapes, enhancing flavor development through precise manipulation. Machine shaping uses automated equipment to ensure consistent size, uniform texture, and higher production rates, ideal for large-scale bakery operations. The choice between hand shaping and machine shaping impacts product quality, production efficiency, and bakery scale.

Key Differences Between Hand Shaped and Machine Shaped Bakery Products

Hand shaping bakery products allows for unique textures and artisanal qualities, resulting in irregular shapes and varied crumb structures that enhance flavor complexity. Machine shaping provides consistent size, uniformity, and faster production rates, ideal for mass-market bakery items. The choice between hand shaped and machine shaped products affects the product's texture, appearance, and overall consumer perception of quality.

Impact on Product Consistency and Quality

Hand shaping in bakery allows bakers to control dough texture and gas retention, resulting in artisanal bread with unique crumb structure and flavor profiles, though it may introduce slight variability between batches. Machine shaping ensures uniform dough handling, enhancing product consistency and reducing defects, which is essential for large-scale production demanding standardized loaf size and shape. Both methods influence crust formation and moisture retention, affecting the final quality, with hand shaping favored for specialty breads and machine shaping optimized for high-volume, consistent output.

Cost Implications: Manual Labor vs. Automation

Hand shaping in bakery involves significant manual labor costs due to skilled workers required for consistent quality, resulting in higher hourly wages and slower production rates. Machine shaping reduces labor expenses by automating repetitive tasks, increasing throughput and minimizing human error, but entails upfront capital investment and maintenance costs. Balancing these cost implications depends on bakery scale, production volume, and long-term return on investment in automation technology.

Efficiency and Production Speed Comparison

Hand shaping in bakeries offers artisanal quality and precision but significantly limits production speed, handling fewer units per hour compared to machine shaping. Machine shaping automates dough processing, increasing efficiency by producing consistent, uniform pieces at a much faster rate, often multiplying output by three or more times. Efficiency gains from machine shaping reduce labor costs and accommodate high-volume demand, making it ideal for large-scale commercial bakeries.

Effect on Artisan Appeal and Brand Identity

Hand shaping dough enhances artisan appeal by showcasing traditional craftsmanship and unique, irregular textures that convey authenticity and quality. Machine shaping offers consistency and efficiency but may diminish the handcrafted aesthetic that strengthens brand identity rooted in artisanal values. Brands emphasizing handmade techniques often attract customers seeking genuine, artisanal bakery experiences distinguished from mass-produced products.

Customization and Product Versatility

Hand shaping in bakery allows for greater customization and product versatility, enabling bakers to adjust dough textures and shapes to meet specific artisanal standards. Machine shaping offers consistency and speed but limits the ability to create unique, intricate forms tailored to individual preferences. Choosing hand shaping enhances the potential for diverse, handcrafted bakery items, while machine shaping suits high-volume production with uniform results.

Hygiene and Food Safety Considerations

Hand shaping in baking allows for greater control and can reduce cross-contamination risks when proper hygiene protocols are followed, as bakers can clean their hands frequently and avoid contact with contaminated surfaces. Machine shaping enhances consistency and minimizes direct human contact, lowering the likelihood of microbial transmission, but requires rigorous equipment sanitation to prevent bacterial buildup. Ensuring strict hand hygiene for bakers and regular sterilization of shaping machines is critical to maintaining optimal food safety standards in bakery production.

Staff Skills and Training Requirements

Hand shaping in bakery demands skilled craftsmanship and extensive training, fostering a deep understanding of dough texture and elasticity. Machine shaping streamlines production but requires staff trained in equipment operation, maintenance, and troubleshooting to ensure consistency and efficiency. Investing in comprehensive training for both methods enhances product quality and operational productivity.

Making the Right Choice for Your Bakery Business

Hand shaping offers artisanal precision and unique texture ideal for small-batch, specialty breads, enhancing product authenticity and customer appeal. Machine shaping maximizes efficiency and consistency, supporting high-volume production and reducing labor costs crucial for scaling bakery operations. Choosing the right method depends on balancing craftsmanship, production capacity, and the bakery's market positioning to optimize quality and profitability.

Hand Shaping vs Machine Shaping Infographic

bizdif.com

bizdif.com