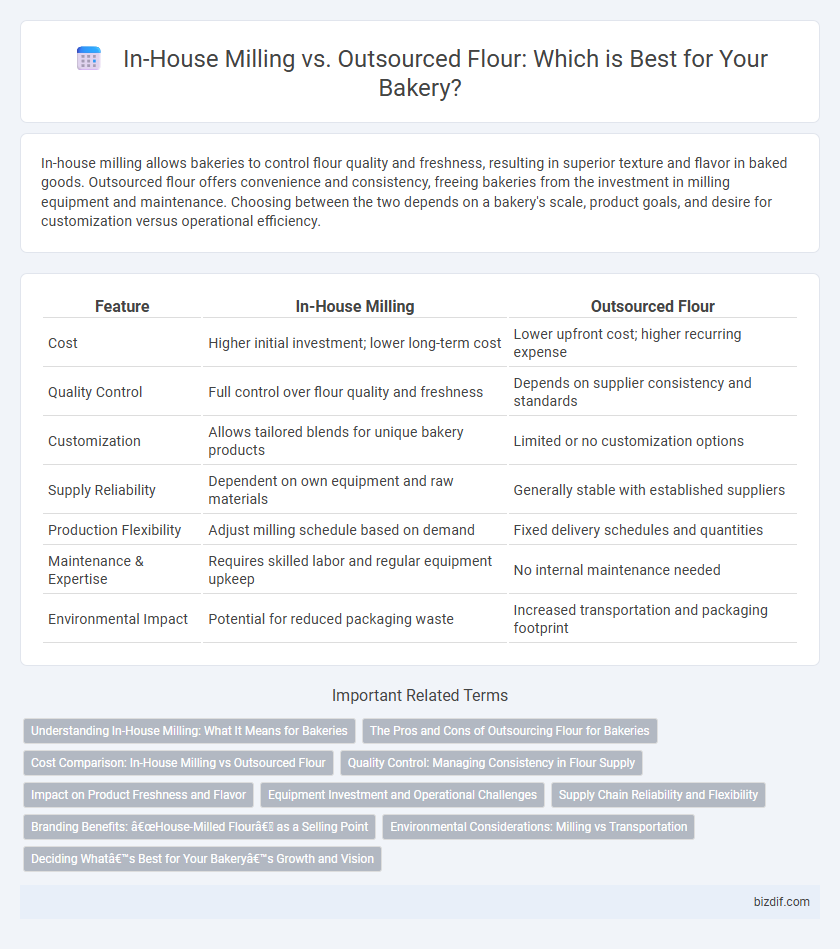

In-house milling allows bakeries to control flour quality and freshness, resulting in superior texture and flavor in baked goods. Outsourced flour offers convenience and consistency, freeing bakeries from the investment in milling equipment and maintenance. Choosing between the two depends on a bakery's scale, product goals, and desire for customization versus operational efficiency.

Table of Comparison

| Feature | In-House Milling | Outsourced Flour |

|---|---|---|

| Cost | Higher initial investment; lower long-term cost | Lower upfront cost; higher recurring expense |

| Quality Control | Full control over flour quality and freshness | Depends on supplier consistency and standards |

| Customization | Allows tailored blends for unique bakery products | Limited or no customization options |

| Supply Reliability | Dependent on own equipment and raw materials | Generally stable with established suppliers |

| Production Flexibility | Adjust milling schedule based on demand | Fixed delivery schedules and quantities |

| Maintenance & Expertise | Requires skilled labor and regular equipment upkeep | No internal maintenance needed |

| Environmental Impact | Potential for reduced packaging waste | Increased transportation and packaging footprint |

Understanding In-House Milling: What It Means for Bakeries

In-house milling allows bakeries to control flour quality by grinding grains on-site, ensuring freshness and tailored flour characteristics that enhance dough texture and flavor. This process reduces dependency on suppliers and enables customization of milling techniques to meet specific recipe requirements, optimizing ingredient performance and product consistency. Investing in milling equipment offers long-term cost savings and supports artisanal baking practices that appeal to quality-conscious consumers.

The Pros and Cons of Outsourcing Flour for Bakeries

Outsourcing flour allows bakeries to access consistent quality and specialized blends without investing in costly milling equipment, reducing upfront expenses and maintenance. However, reliance on external suppliers can lead to supply chain disruptions, less control over flour freshness, and potential variability affecting product consistency. Weighing these pros and cons helps bakeries decide between operational efficiency and maintaining full control over ingredient quality.

Cost Comparison: In-House Milling vs Outsourced Flour

In-house milling reduces long-term costs by eliminating supplier markups and allowing precise control over flour quality, but requires upfront investment in milling equipment and ongoing maintenance expenses. Outsourced flour offers predictable, lower initial costs with bulk purchasing and supplier reliability but may include premium pricing and less flexibility in customization. Evaluating total cost of ownership involves balancing capital expenditure, operational efficiency, and ingredient consistency to determine the most financially viable option for bakery production.

Quality Control: Managing Consistency in Flour Supply

In-house milling enables bakeries to maintain strict quality control by directly monitoring grain selection, milling processes, and flour freshness, ensuring consistent texture and flavor in baked goods. Outsourced flour suppliers may offer convenience but can introduce variability due to differing production standards and supply chain fluctuations. Consistent quality control in flour supply impacts dough performance, crumb structure, and overall product reliability, making in-house milling a preferred choice for artisanal and high-quality bakeries.

Impact on Product Freshness and Flavor

In-house milling enhances product freshness by grinding grains immediately before baking, preserving essential oils and nutrients that contribute to richer flavor profiles and superior texture. Outsourced flour, while convenient, often undergoes extended storage and transportation, leading to potential nutrient degradation and diminished aromatic qualities. Bakeries investing in on-site milling can therefore offer fresher, more flavorful products that differentiate them in quality-conscious markets.

Equipment Investment and Operational Challenges

In-house milling requires significant equipment investment, including grain grinders, sifters, and storage silos, leading to higher upfront costs but greater control over flour quality and customization. Outsourcing flour reduces capital expenditure and simplifies operations but may introduce challenges related to supply chain reliability and limited flour variety. Operationally, in-house milling demands skilled labor and regular maintenance, while outsourced flour relies on consistent vendor performance and bulk storage management.

Supply Chain Reliability and Flexibility

In-house milling enhances supply chain reliability by allowing bakeries to control grain sourcing, processing schedules, and inventory levels, reducing dependence on external suppliers and minimizing disruptions. Flexible production is achieved as in-house milling enables rapid adjustments to flour types and quantities based on demand fluctuations or recipe innovations. Outsourced flour offers convenience but may introduce risks related to supplier availability, shipping delays, and less adaptability to specific bakery needs, impacting overall efficiency.

Branding Benefits: “House-Milled Flour” as a Selling Point

House-milled flour enhances bakery branding by emphasizing authenticity, freshness, and craftsmanship, attracting customers seeking artisanal quality. Highlighting "house-milled flour" in marketing materials creates a unique selling point that distinguishes the bakery from competitors using outsourced flour. This in-house process reinforces the bakery's commitment to quality control and transparency, boosting customer trust and loyalty.

Environmental Considerations: Milling vs Transportation

In-house milling significantly reduces the carbon footprint by eliminating the need for long-distance transportation of flour, which is a major source of greenhouse gas emissions in outsourced supply chains. Milling flour on-site also allows for better control over energy consumption, enabling bakeries to implement more sustainable practices such as using renewable energy sources. Conversely, outsourced flour often involves heavy packaging and frequent deliveries, increasing environmental impact through fuel use, emissions, and waste.

Deciding What’s Best for Your Bakery’s Growth and Vision

In-house milling offers bakeries complete control over flour quality, allowing customization to enhance product uniqueness and freshness, which can directly support brand differentiation and customer loyalty. Outsourced flour provides consistent supply and cost efficiency, reducing the need for specialized equipment and labor, ideal for bakeries focused on scaling quickly and maintaining dependable production. Evaluating your bakery's growth goals, product demands, and operational capacity will determine whether investing in in-house milling or relying on outsourced flour aligns best with your long-term vision.

In-house milling vs Outsourced flour Infographic

bizdif.com

bizdif.com