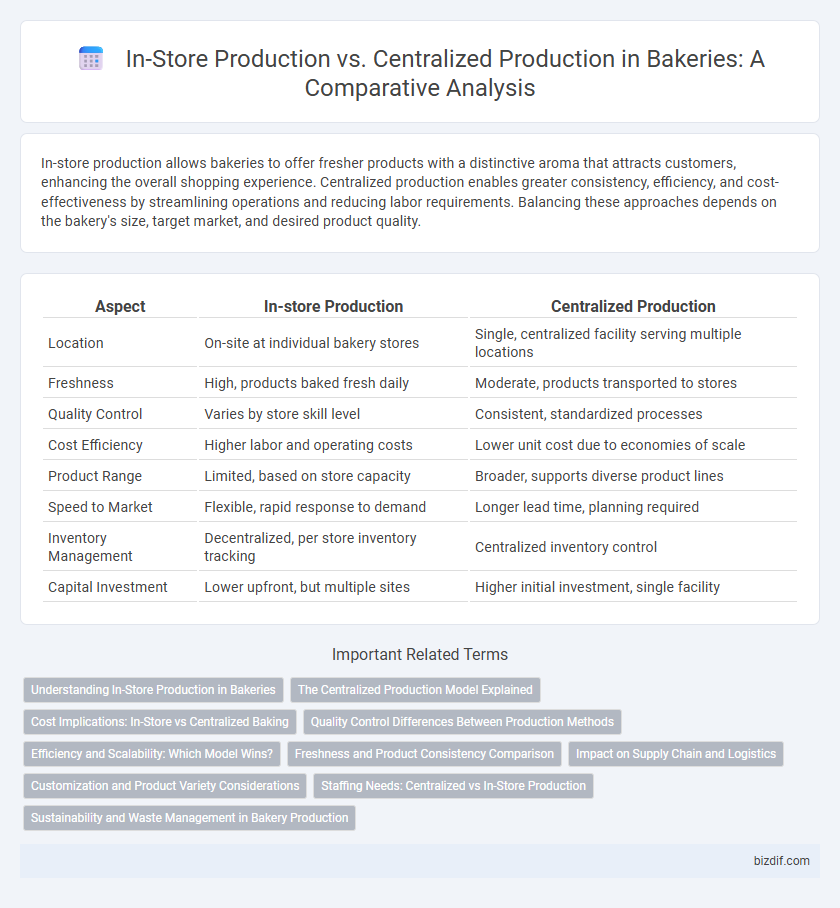

In-store production allows bakeries to offer fresher products with a distinctive aroma that attracts customers, enhancing the overall shopping experience. Centralized production enables greater consistency, efficiency, and cost-effectiveness by streamlining operations and reducing labor requirements. Balancing these approaches depends on the bakery's size, target market, and desired product quality.

Table of Comparison

| Aspect | In-store Production | Centralized Production |

|---|---|---|

| Location | On-site at individual bakery stores | Single, centralized facility serving multiple locations |

| Freshness | High, products baked fresh daily | Moderate, products transported to stores |

| Quality Control | Varies by store skill level | Consistent, standardized processes |

| Cost Efficiency | Higher labor and operating costs | Lower unit cost due to economies of scale |

| Product Range | Limited, based on store capacity | Broader, supports diverse product lines |

| Speed to Market | Flexible, rapid response to demand | Longer lead time, planning required |

| Inventory Management | Decentralized, per store inventory tracking | Centralized inventory control |

| Capital Investment | Lower upfront, but multiple sites | Higher initial investment, single facility |

Understanding In-Store Production in Bakeries

In-store production in bakeries involves preparing fresh baked goods directly on-site, ensuring maximum freshness and allowing for immediate customization based on customer preferences. This approach reduces transportation time and preserves product quality, enhancing the overall customer experience. Bakeries benefit from increased inventory control and responsiveness to daily demand fluctuations through in-store production.

The Centralized Production Model Explained

The centralized production model in bakeries involves producing large batches of baked goods in a single, central facility, which enhances consistency, reduces labor costs, and streamlines quality control. This model supports efficient inventory management and enables faster scaling of operations across multiple retail locations. Centralized production also minimizes waste through precise portion control and optimized use of raw materials.

Cost Implications: In-Store vs Centralized Baking

In-store production often incurs higher labor and utility costs due to smaller batch sizes and less automation compared to centralized baking facilities. Centralized production benefits from economies of scale, reducing per-unit ingredient costs and optimizing energy consumption through advanced equipment. However, transportation expenses and potential quality control challenges can offset some of these savings in centralized baking operations.

Quality Control Differences Between Production Methods

In-store production allows for immediate quality control through direct oversight by bakers, ensuring freshness and customization tailored to local customer preferences. Centralized production benefits from standardized processes and advanced technology, promoting consistent product quality across multiple retail locations. Quality control in centralized facilities relies heavily on batch testing and automated systems, while in-store production emphasizes hands-on inspections and real-time adjustments.

Efficiency and Scalability: Which Model Wins?

In-store production offers flexibility and freshness, enabling bakeries to tailor products to local customer preferences, but often faces limitations in efficiency and scalability due to smaller batch sizes and inconsistent quality control. Centralized production leverages economies of scale, standardized processes, and advanced machinery to boost output and maintain uniform quality across multiple locations, making it more efficient and scalable for large bakery chains. Ultimately, centralized production wins in efficiency and scalability, while in-store production excels in customization and local responsiveness.

Freshness and Product Consistency Comparison

In-store production ensures maximum freshness by baking products on-site, allowing immediate availability and optimal taste for customers. Centralized production offers superior product consistency through standardized processes and quality control across all bakery locations. Balancing freshness and consistency depends on bakery scale, customer demands, and distribution logistics.

Impact on Supply Chain and Logistics

In-store production reduces dependency on complex logistics by enabling fresh product creation closer to customers, minimizing transportation costs and delivery times within the supply chain. Centralized production streamlines operations by consolidating baking processes, which enhances inventory management and facilitates bulk ingredient procurement but increases reliance on efficient distribution networks to maintain product freshness. Balancing these approaches impacts supply chain agility, transportation logistics, and inventory turnover rates in bakery operations.

Customization and Product Variety Considerations

In-store production enables bakeries to offer greater customization and a wider variety of fresh products tailored to local customer preferences, enhancing customer satisfaction and loyalty. Centralized production often limits the range of product options due to standardized processes, but it benefits from economies of scale and consistent quality control. Balancing in-store and centralized production allows bakeries to optimize product variety while maintaining efficiency and cost-effectiveness.

Staffing Needs: Centralized vs In-Store Production

Centralized production in bakeries typically requires fewer specialized staff on-site, concentrating skilled bakers and production workers in a single facility to maximize efficiency and reduce labor costs. In-store production demands a higher number of versatile staff trained in both baking and customer service, increasing overall labor needs and potentially raising expenses. Staffing strategies must balance operational efficiency with product freshness and customer experience to optimize bakery performance.

Sustainability and Waste Management in Bakery Production

In-store production reduces transportation emissions and allows bakeries to tailor production to immediate demand, minimizing food waste and unsold inventory. Centralized production streamlines resource use, enabling efficient energy management and larger-scale waste recycling programs that optimize sustainability efforts. Both methods benefit from advanced forecasting and inventory systems, but in-store baking excels in reducing packaging waste by selling fresh products directly to consumers.

In-store production vs Centralized production Infographic

bizdif.com

bizdif.com