Manual scoring in bakery pet products relies on human expertise to assess texture and quality, ensuring nuanced judgment in each batch. Machine scoring offers greater consistency and speed by using automated sensors and algorithms to evaluate product attributes with precision. Choosing between manual and machine scoring depends on balancing the need for traditional quality control with the demands of high-volume production.

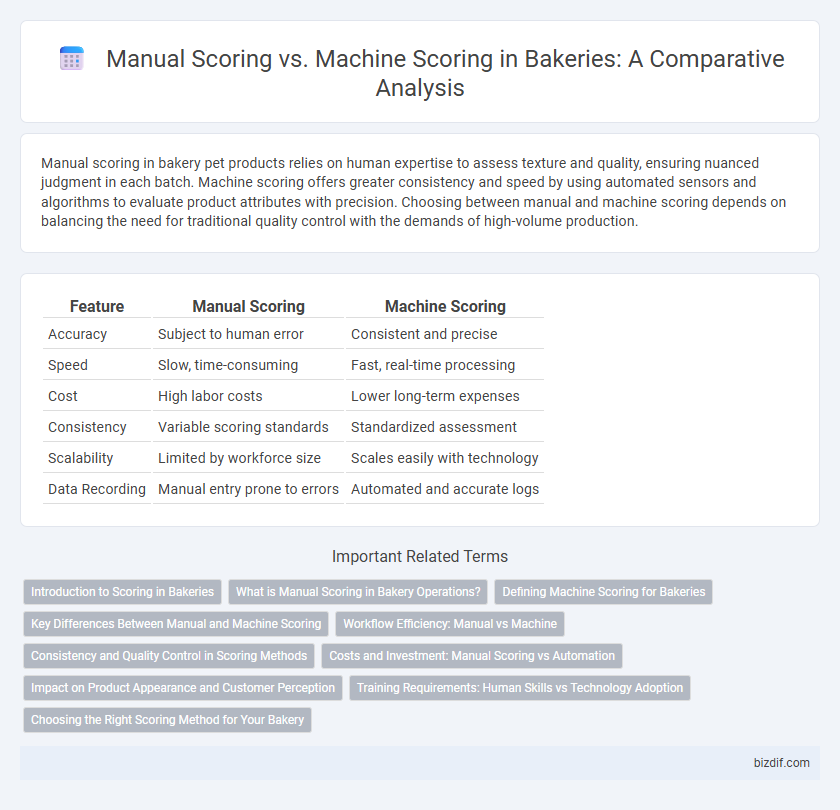

Table of Comparison

| Feature | Manual Scoring | Machine Scoring |

|---|---|---|

| Accuracy | Subject to human error | Consistent and precise |

| Speed | Slow, time-consuming | Fast, real-time processing |

| Cost | High labor costs | Lower long-term expenses |

| Consistency | Variable scoring standards | Standardized assessment |

| Scalability | Limited by workforce size | Scales easily with technology |

| Data Recording | Manual entry prone to errors | Automated and accurate logs |

Introduction to Scoring in Bakeries

Scoring in bakeries refers to the deliberate cutting of dough surfaces to control expansion during baking and create decorative patterns. Manual scoring relies on the baker's skill and intuition, using tools like lame knives to make precise cuts that influence the bread's texture and appearance. Machine scoring offers consistent, high-speed cuts with programmable settings, enhancing production efficiency while maintaining uniform quality.

What is Manual Scoring in Bakery Operations?

Manual scoring in bakery operations involves the skilled process of hand-cutting dough surfaces to control expansion during baking, ensuring optimal crust formation and aesthetic appeal. This technique allows bakers to regulate oven spring and dictate the final bread shape, texture, and crumb structure. Precision and experience are crucial for consistent results, as manual scoring directly influences baking quality and product differentiation.

Defining Machine Scoring for Bakeries

Machine scoring in bakeries involves using automated equipment to cut precise, consistent slashes on bread dough before baking, enhancing both appearance and expansion control. This technology ensures uniform patterns that improve oven spring and crust texture, leading to higher-quality products and reduced labor costs. By integrating machine scoring, bakeries achieve scalable efficiency and maintain product consistency across large batches.

Key Differences Between Manual and Machine Scoring

Manual scoring in bakeries involves skilled workers inspecting and cutting dough by hand, ensuring precise control over texture and design through tactile feedback. Machine scoring automates the process using programmable blades for consistent depth and pattern, significantly increasing production speed and uniformity. Key differences include human judgment and flexibility in manual scoring versus the efficiency, accuracy, and repeatability offered by machine scoring systems.

Workflow Efficiency: Manual vs Machine

Manual scoring in bakeries relies on skilled workers to assess product quality, which can slow down production due to human error and fatigue. Machine scoring uses automated systems with sensors and AI to rapidly evaluate dough texture and consistency, significantly increasing throughput and accuracy. This shift enhances workflow efficiency by reducing inspection time and enabling real-time adjustments during the baking process.

Consistency and Quality Control in Scoring Methods

Manual scoring in bakery quality control relies heavily on human judgment, which can lead to variability and inconsistencies in evaluating product attributes. Machine scoring employs sensors and algorithms that ensure uniformity and objective analysis, significantly enhancing the consistency of quality assessments. Implementing automated scoring methods improves repeatability and reduces errors, providing more reliable data for maintaining bakery product standards.

Costs and Investment: Manual Scoring vs Automation

Manual scoring in bakeries involves lower upfront costs but demands significant ongoing labor expenses and time investments, impacting overall efficiency. Automation requires a higher initial investment in machinery and technology but reduces long-term labor costs and increases scoring precision and consistency. Evaluating cost-benefit reveals that automation delivers greater return on investment through enhanced productivity and reduced waste over time.

Impact on Product Appearance and Customer Perception

Manual scoring in bakery allows for precise control over dough patterns, enhancing the artisanal appearance of bread and appealing to customers seeking handcrafted quality. Machine scoring ensures consistent and uniform cuts, improving production efficiency but sometimes resulting in less distinctive aesthetics. Customer perception often favors the traditional look achieved by manual scoring, associating it with authenticity and premium value.

Training Requirements: Human Skills vs Technology Adoption

Manual scoring in bakeries demands extensive training in sensory evaluation, requiring bakers to develop acute taste, smell, and texture recognition skills through hands-on experience. Machine scoring leverages advanced sensors and AI technology, necessitating training focused on operating and maintaining automated systems rather than honing sensory abilities. Investing in technology adoption streamlines quality control processes, but successful implementation depends on staff proficiency with digital tools and data interpretation.

Choosing the Right Scoring Method for Your Bakery

Choosing the right scoring method for your bakery depends on production volume, consistency needs, and budget constraints. Manual scoring offers artisanal precision and control, ideal for small batches and specialty breads, while machine scoring ensures uniformity and speed, suitable for high-volume operations. Evaluate factors like dough type, desired crust texture, and scalability to select a scoring method that enhances product quality and efficiency.

Manual Scoring vs Machine Scoring Infographic

bizdif.com

bizdif.com