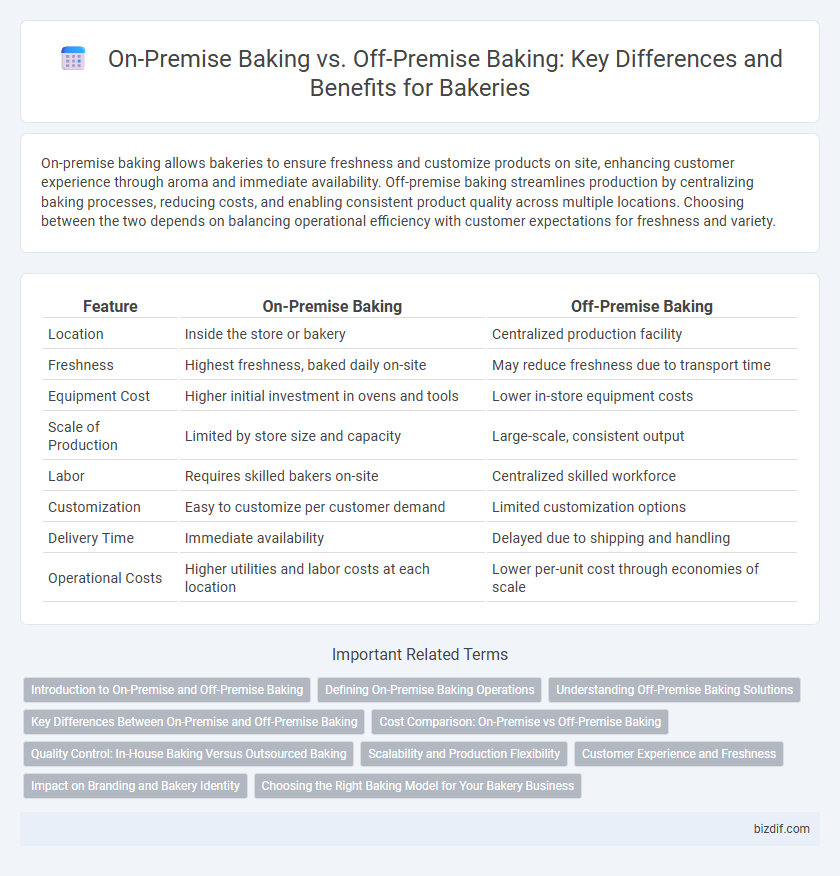

On-premise baking allows bakeries to ensure freshness and customize products on site, enhancing customer experience through aroma and immediate availability. Off-premise baking streamlines production by centralizing baking processes, reducing costs, and enabling consistent product quality across multiple locations. Choosing between the two depends on balancing operational efficiency with customer expectations for freshness and variety.

Table of Comparison

| Feature | On-Premise Baking | Off-Premise Baking |

|---|---|---|

| Location | Inside the store or bakery | Centralized production facility |

| Freshness | Highest freshness, baked daily on-site | May reduce freshness due to transport time |

| Equipment Cost | Higher initial investment in ovens and tools | Lower in-store equipment costs |

| Scale of Production | Limited by store size and capacity | Large-scale, consistent output |

| Labor | Requires skilled bakers on-site | Centralized skilled workforce |

| Customization | Easy to customize per customer demand | Limited customization options |

| Delivery Time | Immediate availability | Delayed due to shipping and handling |

| Operational Costs | Higher utilities and labor costs at each location | Lower per-unit cost through economies of scale |

Introduction to On-Premise and Off-Premise Baking

On-premise baking refers to the process where bakers prepare and bake products directly within the retail or dining location, ensuring freshness and immediate availability for customers. Off-premise baking involves producing bakery items in a separate, centralized facility before transporting them to various sales points, which can enhance efficiency and scalability. Each method impacts product quality, operational costs, and supply chain logistics differently in the bakery industry.

Defining On-Premise Baking Operations

On-premise baking operations involve preparing and baking products directly within the bakery location, ensuring freshness and immediate availability to customers. This approach allows for tight quality control, customization, and the ability to respond quickly to customer preferences and demand fluctuations. Equipment such as industrial ovens, proofing cabinets, and dough mixers are essential components that support efficient on-site production processes.

Understanding Off-Premise Baking Solutions

Off-premise baking solutions enable bakeries to expand production capacity without investing in additional retail space by using centralized commissaries or satellite kitchens. These facilities optimize resource management, improve consistency, and streamline logistics through bulk ingredient handling and large-scale ovens. Leveraging off-premise baking reduces overhead costs while maintaining product quality and meeting increasing consumer demand efficiently.

Key Differences Between On-Premise and Off-Premise Baking

On-premise baking involves preparing and baking goods directly at the bakery location, ensuring fresher products and immediate quality control, while off-premise baking occurs at a separate facility and requires transportation to the point of sale. On-premise baking allows for customization and rapid response to customer demand, whereas off-premise baking offers economies of scale, centralized production, and cost efficiencies. The key differences emphasize freshness, control, and flexibility in on-premise baking versus scalability, consistency, and reduced overhead in off-premise baking.

Cost Comparison: On-Premise vs Off-Premise Baking

On-premise baking often requires higher upfront investments in equipment, utilities, and skilled labor, which increases fixed operational costs. Off-premise baking reduces overhead by centralizing production in large-scale facilities, benefiting from economies of scale and lower labor costs. Evaluating cost efficiency depends on production volume, transportation expenses, and the need for freshness, with off-premise baking generally offering cost advantages for large batches and on-premise preferred for customization and immediate availability.

Quality Control: In-House Baking Versus Outsourced Baking

In-house baking ensures stringent quality control by allowing bakers to monitor every stage of the baking process, from ingredient selection to final product inspection, guaranteeing freshness and consistency. Outsourced baking often faces challenges in maintaining uniform quality due to less direct oversight and potential variations in supplier standards. Bakeries prioritizing premium taste and product reliability typically favor on-premise baking to uphold strict quality benchmarks.

Scalability and Production Flexibility

On-premise baking offers limited scalability due to fixed kitchen space and equipment, restricting production volume and menu variety. Off-premise baking enables greater scalability by utilizing centralized facilities with advanced technology, allowing bulk production and streamlined distribution. This model enhances production flexibility through scalable operations and rapid adaptation to fluctuating demand or seasonal product lines.

Customer Experience and Freshness

On-premise baking ensures customers experience the aroma and freshness of bread straight from the oven, enhancing satisfaction and engagement. Off-premise baking offers convenience by delivering products to multiple locations but may compromise freshness due to transportation and storage. Balancing these methods involves optimizing freshness through efficient logistics and maintaining the sensory appeal that on-site baking guarantees.

Impact on Branding and Bakery Identity

On-premise baking enhances bakery identity by allowing fresh aromas and visual appeal to strengthen local brand recognition and customer loyalty. Off-premise baking supports scalability and consistent product quality but may dilute the sensory brand experience essential for building a strong bakery identity. Balancing both approaches can optimize brand presence while meeting production demands.

Choosing the Right Baking Model for Your Bakery Business

On-premise baking ensures fresh, aromatic products that enhance customer experience and loyalty by producing goods directly at the bakery location. Off-premise baking offers scalability and cost savings by centralizing production in a dedicated facility, optimizing efficiency, and maintaining consistent quality. Bakers must evaluate factors like product freshness, operational costs, space constraints, and customer expectations to choose the right baking model for their business success.

On-premise baking vs Off-premise baking Infographic

bizdif.com

bizdif.com