Scratch baking offers superior flavor and texture by using fresh, high-quality ingredients and allowing full control over the dough-making process. Frozen dough provides convenience and consistency, enabling bakeries to save time and reduce labor costs while ensuring product uniformity. Choosing between the two depends on balancing the desire for artisanal quality with operational efficiency.

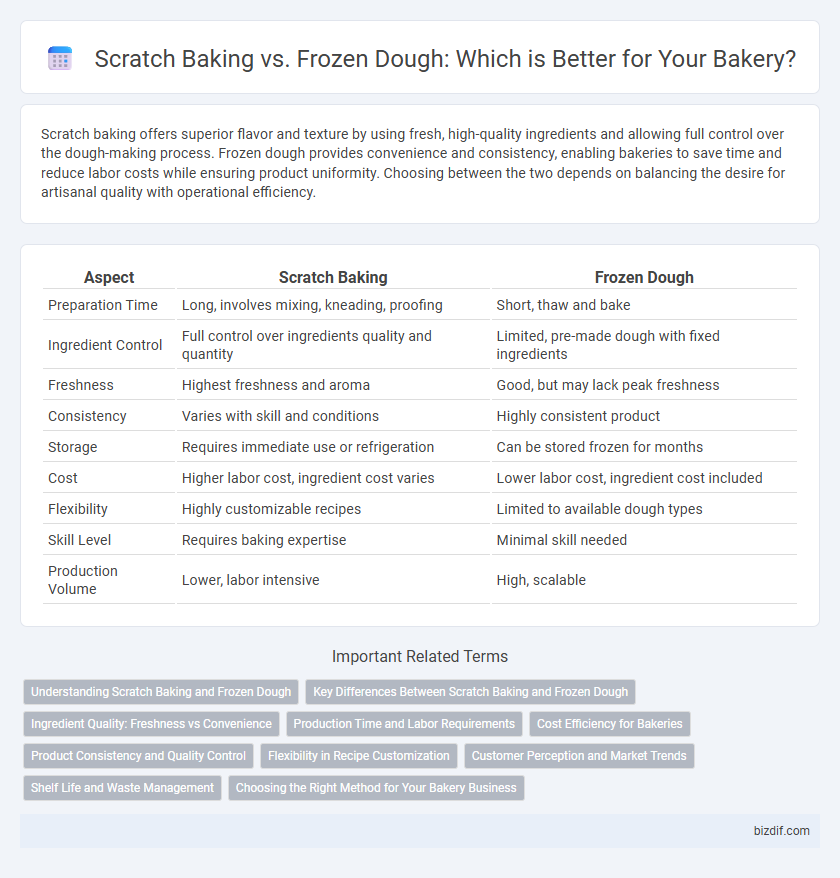

Table of Comparison

| Aspect | Scratch Baking | Frozen Dough |

|---|---|---|

| Preparation Time | Long, involves mixing, kneading, proofing | Short, thaw and bake |

| Ingredient Control | Full control over ingredients quality and quantity | Limited, pre-made dough with fixed ingredients |

| Freshness | Highest freshness and aroma | Good, but may lack peak freshness |

| Consistency | Varies with skill and conditions | Highly consistent product |

| Storage | Requires immediate use or refrigeration | Can be stored frozen for months |

| Cost | Higher labor cost, ingredient cost varies | Lower labor cost, ingredient cost included |

| Flexibility | Highly customizable recipes | Limited to available dough types |

| Skill Level | Requires baking expertise | Minimal skill needed |

| Production Volume | Lower, labor intensive | High, scalable |

Understanding Scratch Baking and Frozen Dough

Scratch baking involves mixing raw ingredients from the beginning, allowing precise control over flavor, texture, and ingredient quality, resulting in fresh, artisanal baked goods. Frozen dough is pre-made and stored at low temperatures, offering convenience and consistency by reducing preparation time and labor in commercial bakeries. Understanding the trade-offs between scratch baking's customization and frozen dough's efficiency is essential for bakery operations aiming to balance quality with productivity.

Key Differences Between Scratch Baking and Frozen Dough

Scratch baking offers full control over ingredient quality and recipe customization, resulting in fresher, more flavorful bread with superior texture and aroma. Frozen dough provides convenience by reducing preparation time and labor while maintaining consistent product quality, though it may lack the depth of flavor found in scratch-made baked goods. The key differences lie in freshness, flexibility, and time investment, impacting both final product quality and operational efficiency in bakery production.

Ingredient Quality: Freshness vs Convenience

Scratch baking uses fresh, high-quality ingredients such as unprocessed flour, fresh yeast, and natural sugars, resulting in superior flavor and texture. Frozen dough offers convenience with pre-mixed components, but may contain preservatives and stabilizers that impact freshness and taste. Prioritizing ingredient quality in scratch baking enhances nutritional value and allows bakers to customize recipes for optimal freshness.

Production Time and Labor Requirements

Scratch baking demands significantly more production time and skilled labor, as it involves mixing, proofing, and shaping dough from basic ingredients. Frozen dough reduces production time by minimizing proofing duration and streamlining preparation, allowing for quicker baking cycles. Labor requirements decrease with frozen dough, as workers mainly handle thawing and baking tasks instead of detailed dough preparation.

Cost Efficiency for Bakeries

Scratch baking requires higher upfront labor and ingredient costs but offers greater control over quality and product differentiation, which can boost long-term profitability for bakeries. Frozen dough reduces labor expenses and ingredient waste through standardized portioning and extended shelf life, making it a cost-effective choice for high-volume production. Balancing scratch baking and frozen dough utilization allows bakeries to optimize operational efficiency while maintaining product consistency and customer satisfaction.

Product Consistency and Quality Control

Scratch baking allows for precise control over ingredient quality and mixing processes, resulting in consistent texture and flavor tailored to specific recipes. Frozen dough often faces variability due to storage conditions and thawing times, which can impact yeast activity and dough performance. Implementing rigorous quality control measures in scratch baking enhances product reliability and customer satisfaction.

Flexibility in Recipe Customization

Scratch baking offers unparalleled flexibility in recipe customization, allowing bakers to adjust ingredients, flavors, and textures to meet specific preferences or dietary requirements. Frozen dough, while convenient, limits the ability to modify recipes since the base formulation is predetermined and standardized. This constraint makes scratch baking ideal for artisans seeking creative control and unique product differentiation in their bakery offerings.

Customer Perception and Market Trends

Scratch baking is perceived by customers as a hallmark of quality and freshness, often associated with artisanal craftsmanship and superior flavor profiles. Market trends indicate a growing demand for transparency and authenticity, leading to increased preference for scratch-made products over frozen dough, which is sometimes viewed as less fresh or mass-produced. However, frozen dough remains popular in fast-paced retail environments due to cost efficiency and consistent product availability.

Shelf Life and Waste Management

Scratch baking offers a shorter shelf life compared to frozen dough, which can be stored for extended periods without compromising quality. Frozen dough minimizes waste by allowing bakers to produce only what is needed, reducing leftover product spoilage. Efficient waste management practices highlight frozen dough's advantage in maintaining freshness while lowering disposal costs in bakery operations.

Choosing the Right Method for Your Bakery Business

Choosing between scratch baking and frozen dough depends on your bakery's scale, desired product quality, and operational efficiency. Scratch baking offers superior flavor and customization, ideal for artisan bakeries prioritizing freshness and unique recipes. Frozen dough enhances consistency and reduces prep time, suitable for high-volume bakeries aiming to streamline production and minimize labor costs.

Scratch baking vs Frozen dough Infographic

bizdif.com

bizdif.com