A proofing cabinet creates an optimal warm and humid environment to encourage dough fermentation and yeast activity, speeding up the rising process. A retarder controls dough temperature by chilling it, slowing down fermentation to develop flavor and extend shelf life. Bakers choose between proofing cabinets or retarders based on desired dough characteristics and production timing.

Table of Comparison

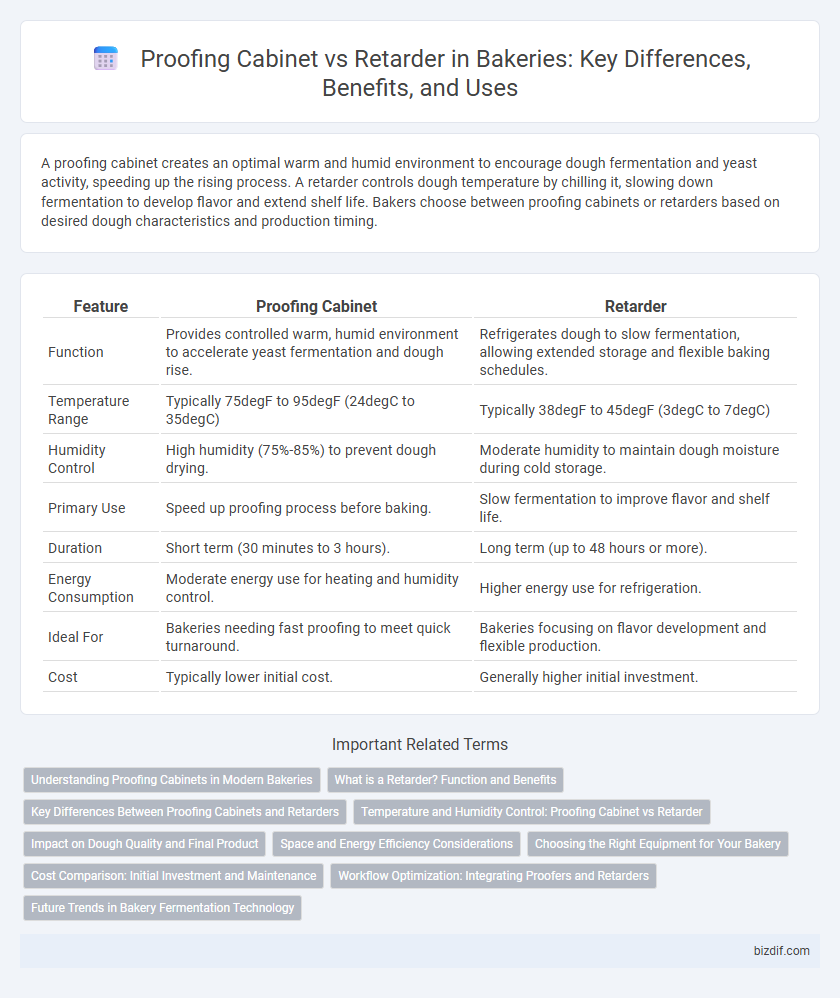

| Feature | Proofing Cabinet | Retarder |

|---|---|---|

| Function | Provides controlled warm, humid environment to accelerate yeast fermentation and dough rise. | Refrigerates dough to slow fermentation, allowing extended storage and flexible baking schedules. |

| Temperature Range | Typically 75degF to 95degF (24degC to 35degC) | Typically 38degF to 45degF (3degC to 7degC) |

| Humidity Control | High humidity (75%-85%) to prevent dough drying. | Moderate humidity to maintain dough moisture during cold storage. |

| Primary Use | Speed up proofing process before baking. | Slow fermentation to improve flavor and shelf life. |

| Duration | Short term (30 minutes to 3 hours). | Long term (up to 48 hours or more). |

| Energy Consumption | Moderate energy use for heating and humidity control. | Higher energy use for refrigeration. |

| Ideal For | Bakeries needing fast proofing to meet quick turnaround. | Bakeries focusing on flavor development and flexible production. |

| Cost | Typically lower initial cost. | Generally higher initial investment. |

Understanding Proofing Cabinets in Modern Bakeries

Proofing cabinets in modern bakeries provide a controlled environment with optimal temperature and humidity levels to promote yeast activation and dough fermentation, ensuring consistent rise and texture. Unlike retarders, which slow fermentation by refrigeration, proofing cabinets accelerate the process, reducing proofing time while maintaining dough quality. These cabinets are essential for bakeries aiming to enhance product uniformity, improve workflow efficiency, and increase daily production capacity.

What is a Retarder? Function and Benefits

A retarder is a specialized refrigeration unit used in bakeries to slow down the fermentation process of dough by maintaining low temperatures, allowing for controlled proofing and extended dough storage. Its primary function is to delay yeast activity, which enhances flavor development, improves dough texture, and increases scheduling flexibility in production. Benefits of using a retarder include reduced over-proofing risk, better consistency in baked goods, and optimized workflow efficiency by enabling dough preparation ahead of baking times.

Key Differences Between Proofing Cabinets and Retarders

Proofing cabinets maintain warm, humid environments to accelerate yeast fermentation, crucial for dough rising, while retarders cool dough to slow fermentation, enhancing flavor development and shelf life. Proofing cabinets typically operate at temperatures between 75degF to 95degF with humidity around 75%-85%, whereas retarders function at temperatures near 38degF to 45degF, preserving dough quality over extended periods. The choice between proofing cabinets and retarders depends on production timing, desired dough characteristics, and bakery workflow efficiency.

Temperature and Humidity Control: Proofing Cabinet vs Retarder

Proofing cabinets maintain a consistent temperature around 85degF with high humidity levels of 75-85% to encourage dough fermentation, while retarders operate at cooler temperatures between 38degF and 45degF with lower humidity to slow yeast activity and extend fermentation. Precise temperature and humidity control in proofing cabinets ensures optimal rising conditions for bread, while retarders provide controlled slow fermentation to develop flavor and texture. Both systems utilize regulated environments, but proofing cabinets focus on warmth and moisture to accelerate proofing, whereas retarders emphasize coolness and moisture retention for fermentation delay.

Impact on Dough Quality and Final Product

Proofing cabinets maintain a controlled warm and humid environment that accelerates yeast activity, resulting in consistent dough rise and enhanced texture in the final baked product. Retarders slow down fermentation by cooling the dough, which improves flavor complexity and extends shelf life without compromising dough strength. Both devices significantly influence dough quality, with proofing cabinets optimizing fermentation speed and retarders enhancing flavor development and dough handling flexibility.

Space and Energy Efficiency Considerations

Proofing cabinets offer rapid dough fermentation in a controlled warm and humid environment, making them ideal for smaller bakeries with limited space due to their compact design. Retarders cool the dough slowly, requiring larger units that consume more energy over extended periods but provide superior flavor development and workflow flexibility. Choosing between the two involves balancing space constraints and long-term energy costs, with proofing cabinets favoring space-saving efficiency and retarders optimizing energy use through temperature control.

Choosing the Right Equipment for Your Bakery

Selecting the right equipment for your bakery hinges on understanding the distinct functions of proofing cabinets and retarders. Proofing cabinets provide controlled warmth and humidity to encourage optimal yeast fermentation, enhancing dough rise and texture. Retarders offer precise temperature control to slow fermentation, extending dough shelf life and improving flavor complexity, making both essential for efficient and high-quality bread production.

Cost Comparison: Initial Investment and Maintenance

Proofing cabinets typically require a lower initial investment compared to retarders, making them more accessible for small to mid-sized bakeries. Maintenance costs for proofing cabinets are generally less expensive due to simpler mechanical components, whereas retarders involve higher upkeep expenses because of their advanced refrigeration and humidity control systems. Evaluating these factors helps bakeries balance upfront costs with long-term operational expenses when choosing between proofing cabinets and retarders.

Workflow Optimization: Integrating Proofers and Retarders

Integrating proofing cabinets and retarders streamlines bakery workflow by allowing precise control over dough fermentation and temperature management, enhancing product consistency. Proofers provide optimal warm conditions for dough rising, while retarders slow fermentation through refrigeration, enabling flexible scheduling. This combination reduces bottlenecks and maximizes productivity by synchronizing proofing stages with production demands.

Future Trends in Bakery Fermentation Technology

Proofing cabinets and retarders are evolving with smart technology integration, allowing precise control over temperature and humidity to optimize yeast fermentation. Emerging trends include IoT-enabled systems that monitor dough conditions in real-time, reducing fermentation time while enhancing bread quality. Advances in fermentation biotechnology emphasize energy efficiency and sustainability, shaping future bakery operations with automated and data-driven proofing solutions.

Proofing cabinet vs Retarder Infographic

bizdif.com

bizdif.com