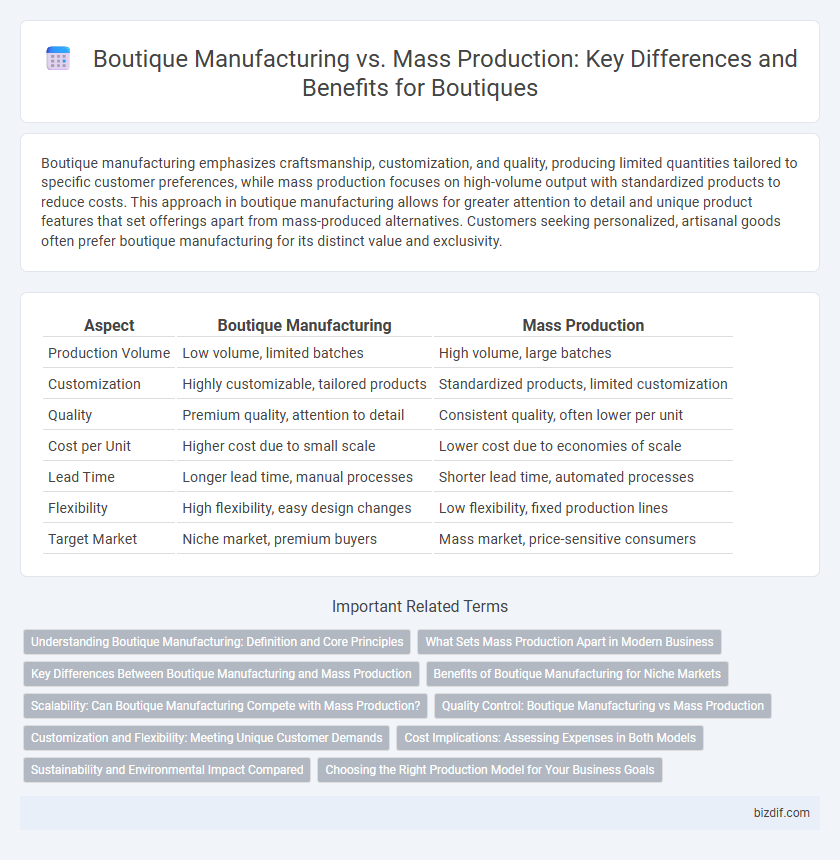

Boutique manufacturing emphasizes craftsmanship, customization, and quality, producing limited quantities tailored to specific customer preferences, while mass production focuses on high-volume output with standardized products to reduce costs. This approach in boutique manufacturing allows for greater attention to detail and unique product features that set offerings apart from mass-produced alternatives. Customers seeking personalized, artisanal goods often prefer boutique manufacturing for its distinct value and exclusivity.

Table of Comparison

| Aspect | Boutique Manufacturing | Mass Production |

|---|---|---|

| Production Volume | Low volume, limited batches | High volume, large batches |

| Customization | Highly customizable, tailored products | Standardized products, limited customization |

| Quality | Premium quality, attention to detail | Consistent quality, often lower per unit |

| Cost per Unit | Higher cost due to small scale | Lower cost due to economies of scale |

| Lead Time | Longer lead time, manual processes | Shorter lead time, automated processes |

| Flexibility | High flexibility, easy design changes | Low flexibility, fixed production lines |

| Target Market | Niche market, premium buyers | Mass market, price-sensitive consumers |

Understanding Boutique Manufacturing: Definition and Core Principles

Boutique manufacturing emphasizes low-volume, high-quality production tailored to niche markets, contrasting with mass production's focus on large-scale output. It relies on skilled craftsmanship, customization, and attention to detail, ensuring unique products that meet specific customer needs. Core principles include flexibility, exclusivity, and maintaining superior standards throughout the manufacturing process.

What Sets Mass Production Apart in Modern Business

Mass production is characterized by high-volume output using standardized processes and automation to maximize efficiency and reduce costs. This approach enables businesses to meet large-scale consumer demand and achieve economies of scale unavailable to boutique manufacturing. Advanced machinery and streamlined workflows in mass production ensure consistent product quality and faster market delivery compared to the customized, labor-intensive focus of boutique production.

Key Differences Between Boutique Manufacturing and Mass Production

Boutique manufacturing emphasizes customized, small-batch production with a focus on craftsmanship, quality, and unique designs, contrasting with mass production's high-volume, standardized output aimed at efficiency and cost reduction. Key differences include the scalability, production speed, and flexibility, where boutique manufacturing allows for greater personalization and attention to detail, while mass production relies on automation and uniformity to meet large consumer demands. Inventory management and resource allocation also vary significantly, with boutique operations often working with limited stock and specialized materials versus the bulk sourcing and streamlined logistics of mass production.

Benefits of Boutique Manufacturing for Niche Markets

Boutique manufacturing offers unparalleled customization and craftsmanship, catering specifically to niche markets with unique product demands. This approach enables smaller production runs with higher quality control, fostering stronger brand loyalty and customer satisfaction. By focusing on specialized products, boutique manufacturers can quickly adapt to market trends and deliver superior value compared to mass production methods.

Scalability: Can Boutique Manufacturing Compete with Mass Production?

Boutique manufacturing offers highly customizable products tailored to specific customer needs, but scalability remains a significant challenge compared to mass production's economies of scale. Mass production excels in rapid, large-volume output with lower per-unit costs, making it ideal for widespread distribution and market penetration. Boutique manufacturers can compete by focusing on niche markets and leveraging advanced technologies like flexible automation to improve scalability without sacrificing uniqueness.

Quality Control: Boutique Manufacturing vs Mass Production

Boutique manufacturing excels in quality control by emphasizing handcrafted precision and rigorous inspection at every stage, ensuring superior product uniqueness and durability. Mass production, while efficient for high volume, relies on automated processes that may compromise individual quality consistency due to standardized assembly lines. Boutique settings adapt swiftly to quality issues, minimizing defects and enhancing customer satisfaction through meticulous attention to detail.

Customization and Flexibility: Meeting Unique Customer Demands

Boutique manufacturing offers unparalleled customization and flexibility, allowing businesses to tailor products precisely to individual customer preferences, unlike mass production which relies on standardized outputs. This approach enables the creation of unique, high-quality items that cater to niche markets or specialized requirements. Meeting unique customer demands through boutique manufacturing fosters brand loyalty and supports innovation within small-scale production environments.

Cost Implications: Assessing Expenses in Both Models

Boutique manufacturing typically incurs higher costs due to smaller production runs, specialized materials, and handcrafted processes, resulting in premium pricing. Mass production benefits from economies of scale, reducing per-unit expenses through automated assembly lines and bulk purchasing of raw materials. Evaluating these cost implications is crucial for businesses to balance product quality and profitability based on target market demands.

Sustainability and Environmental Impact Compared

Boutique manufacturing emphasizes sustainable practices by producing limited quantities with higher quality materials, reducing waste and energy consumption compared to mass production. Mass production often results in significant environmental impact due to large-scale resource use, emissions, and excess inventory waste. Boutique manufacturing supports eco-friendly sourcing and carbon footprint reduction, aligning with increasing consumer demand for sustainability.

Choosing the Right Production Model for Your Business Goals

Boutique manufacturing excels in producing high-quality, customized products tailored to niche markets, making it ideal for businesses prioritizing exclusivity and craftsmanship. Mass production offers cost-efficient, large-scale output suitable for brands aiming to maximize volume and market penetration. Selecting the right production model depends on factors such as product complexity, target audience, budget constraints, and desired scalability to align with specific business objectives.

Boutique Manufacturing vs Mass Production Infographic

bizdif.com

bizdif.com