Batch testing in candle making involves producing a specific quantity and evaluating quality before moving to the next batch, ensuring consistency in scent, color, and burn time. Continuous testing monitors parameters during the entire production process, allowing for real-time adjustments and minimizing defects. Choosing between batch and continuous testing depends on production scale, quality control needs, and operational efficiency goals.

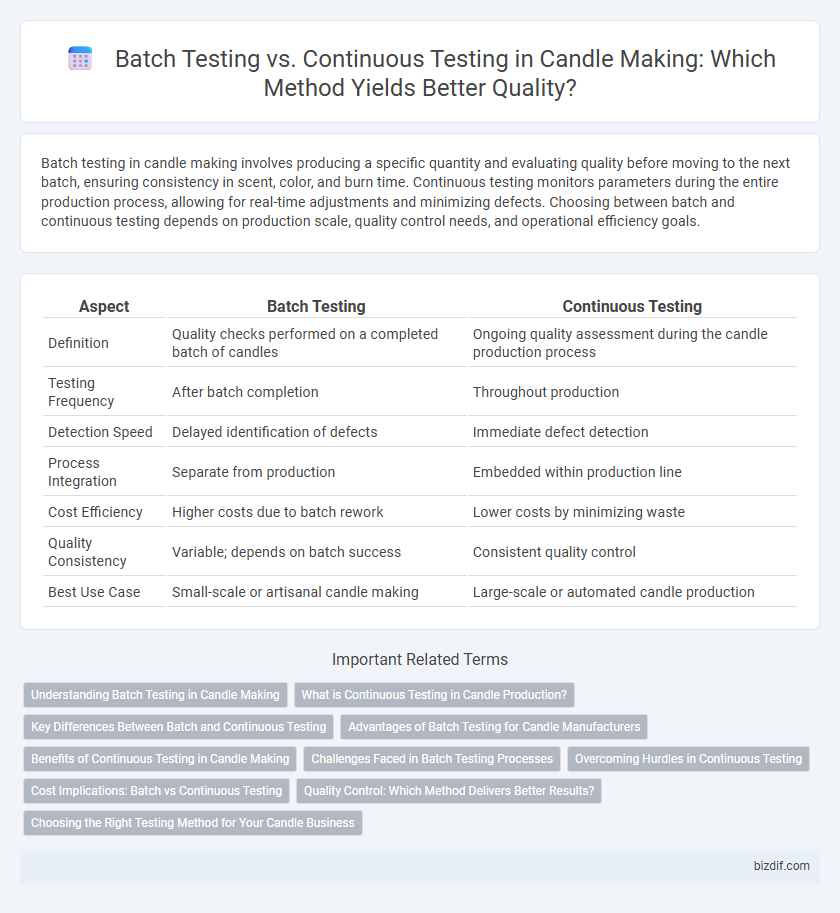

Table of Comparison

| Aspect | Batch Testing | Continuous Testing |

|---|---|---|

| Definition | Quality checks performed on a completed batch of candles | Ongoing quality assessment during the candle production process |

| Testing Frequency | After batch completion | Throughout production |

| Detection Speed | Delayed identification of defects | Immediate defect detection |

| Process Integration | Separate from production | Embedded within production line |

| Cost Efficiency | Higher costs due to batch rework | Lower costs by minimizing waste |

| Quality Consistency | Variable; depends on batch success | Consistent quality control |

| Best Use Case | Small-scale or artisanal candle making | Large-scale or automated candle production |

Understanding Batch Testing in Candle Making

Batch testing in candle making involves producing a specific quantity of candles under controlled conditions to evaluate consistency, scent throw, and burn quality before mass production. This method ensures quality assurance by identifying flaws such as improper wax blend or wick size variations within each batch. Data from batch tests help optimize formulations, ensuring uniform fragrance diffusion and burn time across all candles produced.

What is Continuous Testing in Candle Production?

Continuous testing in candle production involves monitoring and assessing the quality of candles throughout the entire manufacturing process, ensuring consistent fragrance, color, and burn time. This method allows for real-time adjustments to wax temperature, wick placement, and additive ratios, optimizing product uniformity and reducing defects. By implementing continuous testing, manufacturers can maintain high standards, minimize waste, and enhance customer satisfaction with each batch produced.

Key Differences Between Batch and Continuous Testing

Batch testing in candle making involves producing a set quantity of candles at once to evaluate consistency in scent, color, and burn time, ensuring uniform quality before moving to large-scale production. Continuous testing, on the other hand, monitors candle attributes during the entire manufacturing process, allowing for real-time adjustments to maintain product standards. Key differences include batch testing's emphasis on sampling discrete groups versus continuous testing's focus on ongoing quality control throughout production.

Advantages of Batch Testing for Candle Manufacturers

Batch testing for candle manufacturers allows precise control over product quality by testing specific batches before mass production, reducing the risk of defects and inconsistencies. This method facilitates easier identification and isolation of issues within a batch, leading to targeted improvements and cost efficiency. By ensuring uniformity in wax composition, fragrance diffusion, and burn time across each batch, manufacturers can maintain high standards and customer satisfaction.

Benefits of Continuous Testing in Candle Making

Continuous testing in candle making ensures consistent quality by monitoring each production stage, leading to fewer defects and improved product reliability. Real-time feedback allows for quick adjustments in scent ratios, wax temperature, and curing times, enhancing efficiency and reducing waste. This proactive approach supports scalability and meets strict safety standards, ultimately providing a superior candle experience for consumers.

Challenges Faced in Batch Testing Processes

Batch testing in candle making often faces challenges like inconsistent quality due to variations in ingredient mixing and temperature control. Variability between batches can lead to defects such as uneven scent distribution or poor wax texture, impacting overall product quality. Managing these inconsistencies requires meticulous monitoring and increased labor, which can slow production and increase costs.

Overcoming Hurdles in Continuous Testing

Batch testing in candle making isolates each production run for quality checks, while continuous testing integrates real-time monitoring during the manufacturing process. Overcoming hurdles in continuous testing involves implementing advanced sensor technology and automation to detect inconsistencies such as temperature fluctuations and scent dispersion immediately. This approach minimizes defects, reduces waste, and ensures consistent candle quality by allowing instant adjustments without interrupting production flow.

Cost Implications: Batch vs Continuous Testing

Batch testing in candle making incurs higher costs due to the need for multiple setups, downtime between batches, and more frequent quality checks, leading to increased labor and material expenses. Continuous testing reduces waste and labor costs by enabling real-time monitoring and adjustments during production, improving efficiency and minimizing defective candles. Manufacturers benefit from lower operational costs and enhanced production consistency with continuous testing methods.

Quality Control: Which Method Delivers Better Results?

Batch testing in candle making involves evaluating a specific group of candles for consistency in burn time, fragrance release, and safety, ensuring that each batch meets quality standards before distribution. Continuous testing monitors these parameters throughout the production process, quickly identifying defects and allowing real-time adjustments to maintain product reliability. Continuous testing delivers better results by providing ongoing data that enhances overall quality control and reduces the risk of defective candles reaching consumers.

Choosing the Right Testing Method for Your Candle Business

Batch testing involves evaluating a specific group of candles to ensure consistent quality, ideal for small-scale or artisanal candle makers who produce varied scents and designs. Continuous testing monitors every candle throughout the production process, providing real-time quality control crucial for large-scale manufacturers aiming to maintain uniformity and meet industry standards. Selecting the right testing method depends on production volume, product diversity, and the importance of immediate feedback to uphold fragrance potency, burn time, and safety compliance.

Batch testing vs Continuous testing Infographic

bizdif.com

bizdif.com