Hand-poured candles offer a unique artisanal touch with careful attention to detail, ensuring each candle is crafted with precision and care. Machine-poured candles provide consistency and efficiency, allowing for uniformity in size, shape, and wax distribution. Choosing between hand-poured and machine-poured depends on whether you prioritize craftsmanship or mass production.

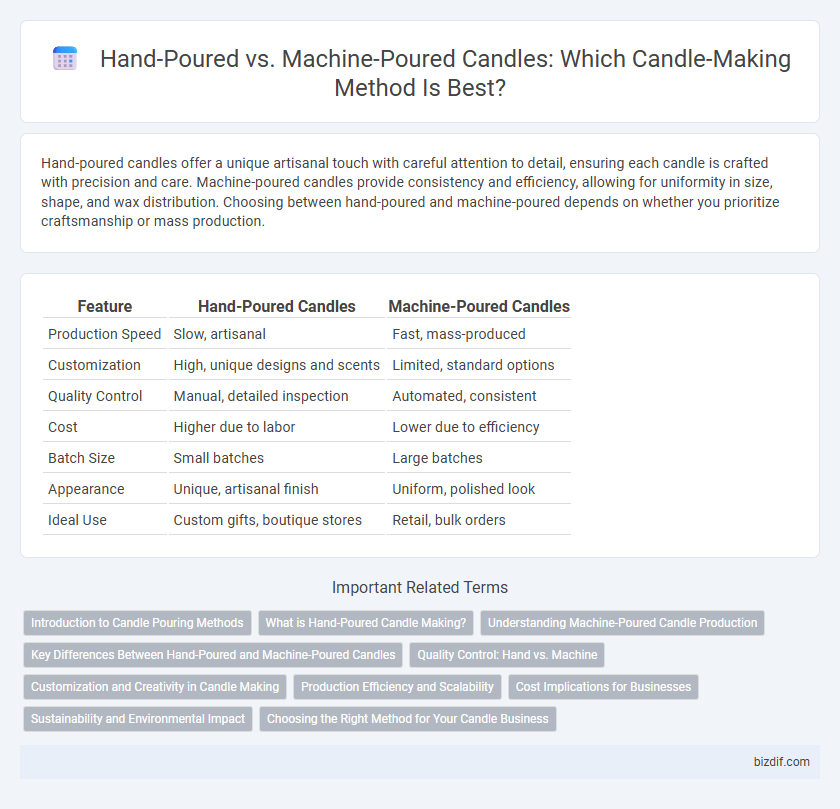

Table of Comparison

| Feature | Hand-Poured Candles | Machine-Poured Candles |

|---|---|---|

| Production Speed | Slow, artisanal | Fast, mass-produced |

| Customization | High, unique designs and scents | Limited, standard options |

| Quality Control | Manual, detailed inspection | Automated, consistent |

| Cost | Higher due to labor | Lower due to efficiency |

| Batch Size | Small batches | Large batches |

| Appearance | Unique, artisanal finish | Uniform, polished look |

| Ideal Use | Custom gifts, boutique stores | Retail, bulk orders |

Introduction to Candle Pouring Methods

Hand-poured candles are crafted individually, allowing for greater control over fragrance intensity and wax texture, often resulting in a more artisanal product. Machine-poured candles, however, offer consistency and efficiency, producing large quantities with uniform appearance and quality. Both methods utilize precise temperature regulation and wax formulation to ensure optimal scent throw and candle burn time.

What is Hand-Poured Candle Making?

Hand-poured candle making involves carefully pouring molten wax into molds or containers manually, allowing greater control over wax temperature and fragrance distribution. This artisanal method ensures unique, high-quality candles with attention to detail, often resulting in smoother finishes and personalized designs. Compared to machine-poured candles, hand-poured candles frequently showcase superior craftsmanship and customization options for candle makers and consumers.

Understanding Machine-Poured Candle Production

Machine-poured candle production involves automated processes that ensure consistent wax temperature and precise pouring volumes, resulting in uniform candle shapes and sizes. This method increases production speed and scalability, making it ideal for large-scale manufacturers aiming for efficiency and cost-effectiveness. Quality control systems integrated into machine-pouring lines help minimize defects and improve overall product reliability compared to hand-poured techniques.

Key Differences Between Hand-Poured and Machine-Poured Candles

Hand-poured candles exhibit unique craftsmanship with attention to detail, often featuring smoother wax surfaces and custom scent blends, while machine-poured candles prioritize uniformity and high-volume production efficiency. The slower cooling process in hand-poured candles enhances scent throw and wax texture, contrasting with the faster, consistent output of machine-poured candles that may sacrifice some artisanal quality. Differences in wick placement precision and wax formulation are also evident, impacting burn time and overall candle performance.

Quality Control: Hand vs. Machine

Hand-poured candles offer meticulous quality control, as artisans monitor temperature and wax consistency throughout the process, ensuring unique, high-quality products. Machine-poured candles provide uniformity and efficiency but may sacrifice the nuanced precision achievable with manual techniques. The choice between hand and machine pouring impacts the candle's finish, scent distribution, and overall craftsmanship.

Customization and Creativity in Candle Making

Hand-poured candles offer unparalleled customization, allowing artisans to experiment with unique scents, colors, and shapes tailored to individual preferences. Machine-poured candles ensure consistency and efficiency but limit creative flexibility, often resulting in uniform designs. Emphasizing creativity, hand-pouring enables candle makers to craft distinctive, personalized products that stand out in the market.

Production Efficiency and Scalability

Hand-poured candles offer artisanal quality and custom details but limit production efficiency due to slower batch processing and manual labor intensity. Machine-poured candles enhance scalability by automating pouring and cooling, significantly increasing output volume while maintaining consistent quality. Manufacturers aiming for large-scale production prioritize machine-pouring methods to optimize cost-effectiveness and meet high demand.

Cost Implications for Businesses

Hand-poured candles typically incur higher labor costs due to the manual process, resulting in increased production expenses compared to machine-poured candles. Machine-poured candles benefit from automation, reducing labor costs and enabling higher output volume, which lowers the per-unit cost. Businesses must balance initial investment in machinery against ongoing labor expenses to optimize profitability in candle production.

Sustainability and Environmental Impact

Hand-poured candles often use sustainable, natural materials such as soy or beeswax, minimizing environmental impact through smaller batch production and reduced energy consumption. Machine-poured candles enable higher volume but frequently rely on paraffin wax and synthetic additives, contributing to greater carbon emissions and plastic waste. Choosing hand-poured candles supports eco-friendly practices by promoting biodegradability and reducing industrial pollution.

Choosing the Right Method for Your Candle Business

Hand-poured candles offer artisanal quality and customization, ideal for boutique candle businesses emphasizing craftsmanship and unique scents. Machine-poured candles enable higher production volumes and consistency, making them suitable for scaling operations and meeting large orders efficiently. Selecting the right method depends on balancing product uniqueness with production capacity and market demand.

Hand-poured vs Machine-poured Infographic

bizdif.com

bizdif.com