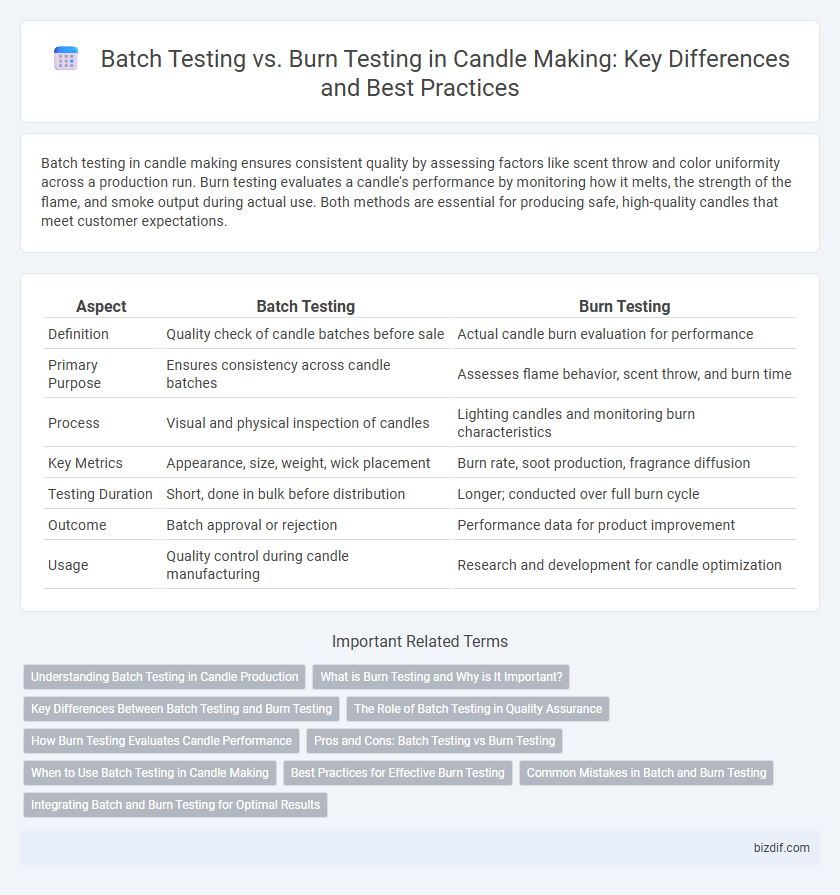

Batch testing in candle making ensures consistent quality by assessing factors like scent throw and color uniformity across a production run. Burn testing evaluates a candle's performance by monitoring how it melts, the strength of the flame, and smoke output during actual use. Both methods are essential for producing safe, high-quality candles that meet customer expectations.

Table of Comparison

| Aspect | Batch Testing | Burn Testing |

|---|---|---|

| Definition | Quality check of candle batches before sale | Actual candle burn evaluation for performance |

| Primary Purpose | Ensures consistency across candle batches | Assesses flame behavior, scent throw, and burn time |

| Process | Visual and physical inspection of candles | Lighting candles and monitoring burn characteristics |

| Key Metrics | Appearance, size, weight, wick placement | Burn rate, soot production, fragrance diffusion |

| Testing Duration | Short, done in bulk before distribution | Longer; conducted over full burn cycle |

| Outcome | Batch approval or rejection | Performance data for product improvement |

| Usage | Quality control during candle manufacturing | Research and development for candle optimization |

Understanding Batch Testing in Candle Production

Batch testing in candle production involves evaluating a specific quantity of candles made under the same conditions to ensure consistency in scent, color, and burn quality. This process verifies that formulations meet safety standards and consumer expectations before full-scale manufacturing. By detecting variations early, batch testing minimizes defects and optimizes product performance across production runs.

What is Burn Testing and Why is It Important?

Burn testing in candle making involves lighting a candle to observe its combustion characteristics, such as wick performance, melt pool formation, and scent throw. This test ensures the candle burns evenly, safely, and efficiently, preventing issues like tunneling, excessive smoke, or uneven melting. Proper burn testing is essential for quality control, customer satisfaction, and regulatory compliance.

Key Differences Between Batch Testing and Burn Testing

Batch testing in candle making evaluates the uniformity and quality of wax, fragrance, and color across an entire production run, ensuring consistency before distribution. Burn testing assesses the candle's performance during combustion, measuring factors like burn time, flame stability, soot production, and scent throw. The key difference lies in batch testing's focus on ingredient and mixture consistency, while burn testing centers on real-world candle behavior and safety during use.

The Role of Batch Testing in Quality Assurance

Batch testing in candle making is essential for maintaining consistent fragrance, color, and wax composition across a production run, ensuring product uniformity and customer satisfaction. This process involves sampling candles from each batch to verify adherence to established quality standards before mass distribution. Accurate batch testing reduces the risk of defects and enhances overall product reliability, complementing burn testing by addressing formulation consistency rather than combustion performance.

How Burn Testing Evaluates Candle Performance

Burn testing evaluates candle performance by measuring burn time, scent throw, and soot production under controlled conditions, providing insights into the candle's overall quality and safety. This process involves lighting the candle for a set duration to observe how evenly the wax melts and how consistently the wick burns, ensuring optimal functionality. Data from burn tests helps manufacturers adjust wick size, wax composition, and fragrance load for improved user experience.

Pros and Cons: Batch Testing vs Burn Testing

Batch testing in candle making provides consistent quality control by evaluating multiple candles simultaneously, saving time and identifying production issues early, but it may miss individual candle defects. Burn testing offers detailed insights into a single candle's performance like burn time, scent throw, and smoke emission, revealing specific product characteristics; however, it is time-consuming and less practical for large-scale production. Choosing between batch and burn testing depends on balancing thorough individual analysis with efficient quality assessment across batches.

When to Use Batch Testing in Candle Making

Batch testing in candle making is essential during the formulation phase to ensure consistency in scent throw, color, and wax performance before large-scale production. It enables makers to identify any variations or defects in a small sample batch, preventing costly mistakes and ensuring product quality. Use batch testing when experimenting with new fragrance oils, wax blends, or wick sizes to optimize the final candle's burn time and safety.

Best Practices for Effective Burn Testing

Effective burn testing in candle making requires selecting representative samples from different batches to ensure consistent fragrance throw and wax performance. Monitor burn characteristics such as wick height, melt pool formation, and soot production over multiple hours to identify potential issues early. Documenting results and adjusting wick size or wax formulation based on test outcomes enhances overall candle quality and safety.

Common Mistakes in Batch and Burn Testing

Common mistakes in batch testing include inconsistent ingredient measurements and neglecting temperature control, leading to uneven candle quality. In burn testing, errors such as improper wick sizing and inadequate safety monitoring result in poor flame performance and potential hazards. Both tests require precise documentation and standardization to ensure reliable, replicable candle production outcomes.

Integrating Batch and Burn Testing for Optimal Results

Integrating batch testing and burn testing in candle making ensures consistent fragrance, color, and burn quality across multiple candle batches. Batch testing verifies raw material consistency and mixture ratios, while burn testing assesses the candle's actual performance, including wick behavior and scent throw. Combining both methods optimizes product reliability, enhances customer satisfaction, and minimizes costly production errors.

Batch testing vs Burn testing Infographic

bizdif.com

bizdif.com